Production System Design and Implementation in... Automotive Components Industry Bukola L. Masha

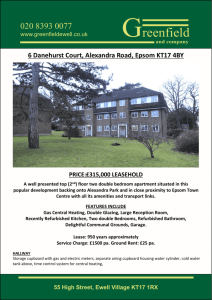

advertisement