Time History Analysis of Axial Forces (Pass ... at Joints in a Braced Frame

advertisement

Time History Analysis of Axial Forces (Pass Through Forces)

at Joints in a Braced Frame

By

Vincent Paschini

B.Eng.

Polytechnique Montreal, 2011

Submitted to the Department of Civil and Environmental Engineering in Partial

Fulfillment of the Requirements for the Degree of Master of Engineering in Civil and

Environmental Engineering at the Massachusetts Institute of Technology

ARCHIVES

JUNE 2012

© 2012 Vincent Paschini. All Rights Reserved

"W SlCUSETS INSTITUTE

JUN 2 2 2

The author hereby grants to MIT permission to reproduce and to

distribute publicly paper and electronic copies of this thesis document in whole or in part

in any medium now known or hereafter created.

Author:

)

Department of Civil and Environmental Engineering

May 1 1 ,th2012

Certified by:

Jerome J. Connor

Environmental

Engineering

Professor of Civil and

Thesis upervisor

II

A

Accepted by:

H idi M. Nepf

Chair, Departmental Committee of Graduate Students

Time History Analysis of Axial Forces (Pass Through Forces)

at Joints in a Braced Frame

By

Vincent Paschini

Submitted to the Department of Civil and Environmental Engineering on May 11 th, 2012

in Partial Fulfillment of the Requirements for the Degree of Master of Engineering in

Civil and Environmental Engineering at the Massachusetts Institute of Technology

ABSTRACT

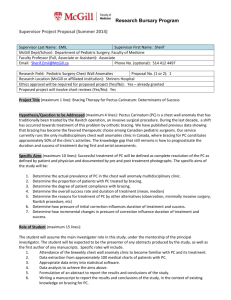

As buildings keep getting taller, traditional braced lateral systems take more loads. This

generates a phenomenon at every joint of a frame called "Pass Through Force". Pass

through forces come from the transfer of axial forces between two side by side

members. Adding a bracing scheme to our frame will introduce even more pass through

forces at the node since part the force in the bracing will be transferred in the horizontal

member.

The main goal of this thesis is to find an appropriate way of computing pass through

forces without being too conservative. If we take an accurate value of pass through

force at a node, the steel connections will not be overdesigned, resulting in cost

savings. In this thesis, we analyse multiple bracing configurations for a typical steel

frame under different load combinations in order to find a procedure for computing pass

through forces adequately. Each scenario will be analysed in detail, a time history

analysis will be used to find precise values under earthquake loading. The results are

compared with two traditional methods of finding pass through forces, and the best

approach is identified.

Thesis Supervisor: Jerome J. Connor

Title: Professor of Civil and Environmental Engineering

Acknowledgements

First of all, I would like to thank my family, girlfriend and friends who greatly

supported me during my whole journey here at MIT. This experience would have been

even harder without their support. I wouldn't be able to do it without you. Thank you for

believing in me and encouraging me. / really appreciate it.

To every professor from the Civil and Environmental Engineering department, but

especially Prof. Jerome J. Connor and his teacher assistant Pierre Ghisbain who helped

me understand every aspect of this thesis. I'm grateful for all the knowledge Prof.

Jerome J. Connor provided me during the last nine months. Thank you, I will never

forget everything I learned in the High Performance Structure program. Again, I really

appreciate it.

To every student in the M.Eng. program and the other ones I met in the past year

for being so kind and always there when I needed to take a time out. I now see you as

friends instead of colleagues and hope to see you again in a near future. Thank you for

those never-ending hours in the M.Eng. room and every special activity we did together.

Once more, I really appreciate it.

To everybody else who crossed my path while I was here at MIT and didn't

mention, thank you. To D.P.H. V. who gave me the idea for this thesis subject. I hope

this thesis will help understanding every concept of pass through forces and even more.

Thank you everybody for the support you gave me, I can't tell you how much I

appreciate it.

- Vincent Paschini

3

TABLE OF CONTENTS

Chapter 1: Introduction ..............................................................................................

10

Chapter 2: Fram e& L

........................................................................................

12

2 .1 F ra m e ...................................................................................................................

12

2 .2 L o ad s ...................................................................................................................

12

2.2.1 Dead L

D ............................................................................................

2.2.2 Live Loads (L & Lr) ...............................

................................................

13

13

2.2.3 Snow Load ( )............................................................................................

13

2.2.4 W ind Loads W ..........................................................................................

14

2.2.5 Earthquake Load (E) .................................................................................

16

Chapter 3: Bracing Configurations ............................................................................

19

Chapter 4: SAP2000 Model........................................................................................

22

4.1 Building the M odel ............................................................................................

22

4.2 M assachusetts Earthquake Scaling ..................................................................

23

4.3 Tim e History Analysis Detail ............................................................................

26

Chapter 5: Results ........................................................................................................

29

Chapter 6: Analysis & Com parison.............................................................................

34

6.1 Analysis................................................................................................................

34

6.1.1 Bracing Configuration 1 ..............................................................................

34

4

TABLE OF CONTENTS (CONTINUED)

6.1.2 Bracing Configuration 2 ............................................................................

. 35

6.1.3 Bracing Configuration 3 ............................................................................

. 36

6.1.4 Bracing Configu ration 4 ............................................................................

. 36

6.1.5 Bracing Configuration 5 ............................................................................

. 37

6.1.6 Bracing Configuration 6 ............................................................................

. 38

6.1.7 Bracing Configuration 7 ............................................................................

. 38

6.1.8 Bracing Configuration 8 ............................................................................

. 39

6.1.9 Bracing Configuration 9 ............................................................................

. 40

6 .2 Co m pa riso n ..........................................................................................................

40

6.2.1 1st Method ...................................................................................................

41

Method .................................................................................................

42

6.3 Moving Forward ..............................................................................................

45

6.2.2

2 nd

Chapter 7: Conclusion...............................................................................................

47

R e fe re n c es ....................................................................................................................

49

B oo k ...........................................................................................................................

49

W e bs ite ......................................................................................................................

49

Pro g ra m .....................................................................................................................

50

Appendix A: Axial Forces in Members..........................................................................

51

5

TABLE OF CONTENTS (CONTINUED)

A ppendix B : PT F at N odes........................................................................................

61

Appendix C: 1 st Method Comparison........................................................................

71

Appendix D:

74

2 nd

Method Bracing Force Finding & PTFs ...........................................

6

LIST OF FIGURES

Figure 1 - Pass Through Force (PTF) ......................................................................

10

Figure 2 - Wind Pressure Diagram ............................................................................

16

Figure 3 - Typical Frame Overview ...........................................................................

18

F ig ure 4 - Typ ica l F ram e .............................................................................................

110

Figure 5 - Bracing Configuration 1 .............................................................................

16

Figure 6 - Bracing Configuration 2 ...........................................................................

20

Figure 7 - Bracing Configuration 3 ...........................................................................

20

Figure 8 - Bracing Configuration 4 ...........................................................................

20

Figure 9 - Bracing Configuration 5 ...........................................................................

20

Figure 10 - Bracing Configuration 6..........................................................................

20

Figure 11 - Bracing Configuration 7..........................................................................

20

Figure 12 - Bracing Configuration 8..........................................................................

21

Figure 13 - Bracing Configuration 9..........................................................................

21

Figure 14 - Members & Nodes Numbering................................................................

22

Figure 15 - Altadena Response Spectrum Proprieties ..............................................

23

Figure 16 - Massachusetts Response Spectrum Proprieties.....................................

24

Figure 17 - Assign Load Case Type to the Earthquake Load....................................

24

Figure 18 - Max. Displacement (Altadena Static Quake............................................

25

Figure 19 - Max. Displacement (Massachusetts Static Quake).................................

26

Figure 20 - Time History Function ..............................................................................

27

Figure 21 - Apply the Scale Factor to the Load Case................................................

27

Figure 22 - Example of Foce Envelopes Under a Dynamic Earthquake ...................

28

7

LIST OF FIGURES (CONTINUED)

Figure 23 - Reminder of Members & Nodes Numbering ...........................................

33

Figure 24

PTFs Sketch (Bracing Configuration 1) .......................................................

34

Figure 25

PTFs Sketch (Bracing Configuration 2 ) .......................................................

35

Figure 26

PTFs Sketch (Bracing Configuration 3 ) .......................................................

36

Figure 27

PTFs Sketch (Bracing Configuration 4 ) .......................................................

36

Figure 28

PTFs Sketch (Bracing Configuration 5 ) .......................................................

37

Figure 29

PTFs Sketch (Bracing Configuration 6 ).......................................................

38

Figure 30

PTFs Sketch (Bracing Configuration 7 ) ..........................

Figure 31

PTFs Sketch (Bracing Configuration 8 ) .......................................................

39

Figure 32

PTFs Sketch (Bracing Configuration 9 ) .......................................................

40

Figure 33

Bracing Numbering (Bracing Configuration 1)............................................. 42

Figure 34

Force Equilibrium at node 11 (Bracing Configuration 1) .............................

43

Figure 35 Complex Steel Connection..........................................................................

46

............................. 38

8

LIST OF TABLES

Table 1 - Loads S um m ary ..........................................................................................

17

Table 2 - Load Combinations .....................................................................................

18

Table 3 - Axial Forces in Members (Bracing Configuration 1)...................................

29

Table 4 - PTFs (Bracing Configuration 1)..................................................................

31

Table 5 - PTFs (Bracing Configuration 2)..................................................................

32

Table 6 - PTFs (Bracing Configuration 3)..................................................................

32

Table 7 - PTFs (Bracing Configuration 4)..................................................................

32

Table 8 - PTFs (Bracing Configuration 5)..................................................................

32

Table 9 - PTFs (Bracing Configuration 6)..................................................................

32

Table 10 - PTFs (Bracing Configuration 7)...............................................................

32

Table 11 - PTFs (Bracing Configuration 8)...............................................................

33

Table 12 - PTFs (Bracing Configuration 9)...............................................................

33

Table 13 - Design Axial Force of Members (Bracing Configuration 1)....................... 41

Table 14 - Comparison of PTFs using the 1st Method (Bracing Configuration 1) .....

42

Table 15 - Full Axial Force in Diagonal Members (Bracing Configuration 1).............. 43

Table 16 - PTFs

2 nd

Method using 0 = 0 .......

Table 17 - PTFs

2 nd

Method using 0 = 38.660 ..................

......................... 44

...............

44

Table 18 - Reminder of PTFs Calculated for the First Bracing Configuration in Ch. 5 .. 44

9

CHAPTER

1: INTRODUCTION

Steel connection design is an art and can sometimes be costly. The less material

you use, the better it is (as long as the connection capacity is greater than the demand).

With buildings getting taller year after year, lateral systems need to be efficient in order

to counter wind and earthquake loads. Depending on the lateral system of the building,

the axial forces between two side by side members can be different. If we look at a

conventional braced frame, the horizontal component of the force in the bracing adds an

axial force at the joint.

-

-7

Fbmn

F

Joint

F

Figure 1 - Pass Through Force (PTF)

This additional force between two members is called "Pass Through Force"

(PTF) and results in an extra check in the connection design. If the value of the PTF is

not accurate (usually on the conservative side), the connection will be overdesigned and

the cost will increase.

The purpose of this thesis is to find the absolute maximum value of the PTF at

any joint and maybe find an algorithm on how to compute them. To begin with, a typical

frame encounter on a past job will be replicated, and simplified (2D model). Loads and

10

load combinations from the American Society of Civil Engineers (ASCE 7-10) and the

International Building Code (IBC 2012) will be used throughout both static and dynamic

analyses. Lateral wind loads will be analysed in both directions.

For multiple bracing configurations in our frame, the absolute maximum axial

force in every member will be determined through several analyses (using SAP2000) for

different load combinations. A time history analysis will be necessary for the dynamic

part of this thesis in order to obtain accurate results under earthquake loads. Those

analyses will give us force envelopes, which will be helpful to determine the appropriate

PTF at a joint.

Once we obtain adequate results for our first braced frame, the bracing

configuration will be modified in order to find (if possible) an algorithm on how to

compute those forces. The last step of this thesis will be to compare those results with

two traditional methods.

11

CHAPTER

2: FRAME & LOADS

2.1 FRAME

The first thing we needed to define was our frame dimensions & proprieties. The

main frame used throughout this thesis is inspired from a previous frame encountered

on a past job in Colonsay, Saskatchewan, Canada (I was working on this project last

summer, 2011, designing steel connections for DPHV 1 , a structural engineering firm

located in Ste-Doroth6e/Laval, Quebec, Canada). This frame is part of a building used

as a potash mining warehouse. To simplify our analysis, we will look at a 2D version of

this frame and only part of it will be used.

The frame consists of three 25 feet wide bays with four 20 feet high storeys.

According to the structural plans of this job, girders and columns are W16x40 and

W1 8x1 19 steel sections respectively. Columns are fixed at the base and girders pinned

at each joint. Frames in this building are spaced at 20 feet center to center of each

other. A full sketch of the main frame used throughout this thesis and loads applied to it

can be found in figure 3.

2.2 LOADS

We will assume that our building (and its frame) is located in the Boston area,

Massachusetts, United States. The first step in the structural design of our building was

determining the design loadings that would act on the structural members. Throughout

this process, we used the LRFD (Load and Resistance Factor Design) method outlined

in the ASCE 7-10 (American Society of Civil Engineers) Minimum Design Loads for

1 htt://www.dnhv.ca/nages/drDhv

orofile.htm

12

Buildings and Other Structures, and the IBC 2012 (International Building Code). One

categorization that had to be determined before we proceeded to individual loading

types was the risk category, which we determined using Table 1-5.1 from ASCE 7-10.

The risk category of a light warehouse is 11 (2). Every load will be applied as distributed

(knowing our tributary length of 20 feet between each frame) on each floor/wall except

for the earthquake loading, which will be taken as a dynamic load case.

2.2.1 DEAD LOAD (D)

Dead loading applied to our frame consists of the self-weight of our members

plus a 4 inches lightweight concrete (110 pounds per cubic foot) slab on top of them.

Even if the slab thickness is usually smaller at the roof (or non-existent), we will also

apply the full dead load at this location in order to obtain conservative values.

2.2.2 LIVE LOADS (L & LR)

Live loads in our building fell into two categories, interior live load and roof live

load. The typical value of interior live load at each floor for a light warehouse is 125 psf.

The roof live load will be taken as 20 psf. Both values for live loading were taken from

Table 4-1 in ASCE 7-10. No live load reduction will be used, since we are not allowed to

reduce interior live load greater than 100 psf and roof live load.

2.2.3 SNOW LOAD (S)

Snow load for a flat roof top is defined in Chapter 7 of ASCE 7-10. The first thing

we need to define is the Terrain Category as per section 26.7. For our type of building,

the terrain category is B. Using the following equation (7.3-1 of ASCE 7-10):

S = Pf = 0.7CeCtIsP

13

where:

Ce=

Exposure Factor (Table 7-2 of ASCE 7-10)

Ct= Thermal Factor (Table 7-3 of ASCE 7-10)

Is=

Importance Factor (Table 1.5-2 of ASCE 7-10)

Pg=

Ground Snow Load (Figure 7-1 of ASCE 7-10)

we can determine our snow load. The exposure factor (Ce) for a terrain category B with

a fully exposed roof is 0.9. The thermal factor (Ct) for a normal building and the

importance factor (/s) for risk category 11are both 1.0. The ground snow load (Pg) in the

Massachusetts area is 40 psf. Calculating the snow load we obtain Pf = 25.2 psf. To be

conservative and because Massachusetts' winters are usually heavy in snow, we will

use a snow load of 30 psf at the roof.

2.2.4 WIND LOADS (W)

Again, wind loads fell into two categories, lateral (windward) wind pressure on

walls of our building and roof (downward) wind pressure. We won't need to calculate our

leeward wind pressure, because the opposite wall of our frame is connected to the rest

of the building. Lateral wind load will be analysed in both directions. The first thing we

needed to calculate was the velocity pressure coefficient (qz) as per section 27.3.2 of

ASCE 7-10:

qz = 0.00256 - Kz - Kzt - Ka V

2

where:

K2= Velocity Pressure Exposure Coefficient (Table 27.3-1of ASCE 7-10)

Kzt=

Topographic Factor (Table 26.8-1 of ASCE 7-10)

Kd=

Wind Directional Factor (Table 26.6-1 of ASCE 7-10)

v= Wind Speed (Figure 26.5-lA of ASCE 7-10)

14

Wind speed (v) for risk category 11buildings within the Massachusetts area is 140

miles per hour. The wind directional factor (Kd) equals 0.85 for a typical building and the

topographic factor (Kt) for an Exposure Category B (section 26.7 of ASCE 7-10) is 1.0.

The velocity pressure exposure coefficient (Kz) depends on the height of our building,

and values can be found in Table 27.3-1 of ASCE 7-10.

Once we know the velocity pressure coefficient (qz), we can compute both lateral

and roof wind loads with equation 27.4-1 of ASCE 7-10 for a rigid frame:

W = Pw = qzGeCpe - qh[GCp],

where:

Ge=

Cpe =

qh =

Gust Effect Factor (section 26.9 of ASCE 7-10)

External Pressure Coefficient (Figure 27.4-1 of ASCE 7-10)

Velocity Pressure Coefficient at the Roof

[GC,;= Internal Pressure Coefficient (section 26.11 of ASCE 7-10)

The gust effect factor (Ge) is equal to 0.85, while the internal pressure coefficient

([GCp];) is ±0.18 (note that -0.18 will control for the windward wind pressure). For the

windward wind pressure, the external pressure coefficient (Cpe) is 0.8.

Exposure Coef.

Kzo-1 5 = 0.57

Velocity Pressure Coef.

qzo-1 5= 24.31

Windward Wind Load

Pwo. 1 5 = 23.67 psf

Kz20 =

0.62

qz2 0 =

26.44

Pw20 = 25.12

psf

Kz2 5 =

0.66

qz2 5 =

28.14

Pw25 = 26.28

psf

Kz30 =

qz 3 0 =

29.85

Pw3o = 27.44

qz4 0 =

32.41

Pw4 o= 29.18

Kz5 o =

Kz 6 o =

Kz7 o =

0.70

0.76

0.81

0.85

0.89

qz50 =

qZ60 =

34.54

36.25

qz 7 0 =

37.95

Kh =

0.93

PW

5o= 30.63

PW6o = 31.79

Pw7o = 32.95

Pwh = 3 4 .11

psf

psf

psf

psf

psf

psf

Kz40 =

qh= 39.66

15

80

70

60

50

-W

440

indward

Wind

Pressure Calculated

30

-

-W

indward Wind

Pressure for Design

20

10

23

25

27

29

31

Wind Pressure (psf)

33

35

Figure 2 - Wind Pressure Diagram

To be conservative, we will use a value of 35 psf for the lateral windward wind

load. At the roof, Cpe is equal to either -0.9 or -0.18. The roof wind pressure varies from

1.07 psf upward to 37.48 psf downward. Since the uplift is pretty small, we will neglect

its effect and only apply a downward wind pressure at the roof. Again, to be

conservative, we will use a roof wind load of 38 psf.

2.2.5 EARTHQUAKE LOAD (E)

For the earthquake loading, we will use a time history analysis. The result of this

analysis will give us a force envelope for every member in our frame. In order to do this

dynamic analysis, we need the acceleration data from

an earthquake in the

Massachusetts area. Using SAP2000 to do our analyses, the program's default

database doesn't have any value for such a small earthquake. We will have to use a

California earthquake and scale it down. To do so, we will start by doing a static

analysis on our frame for both earthquakes (Massachusetts and California) and find the

16

maximum displacement for each of them. The ratio between both displacements will

give us the scale factor to use for our time history analysis. Even if this ratio doesn't fully

characterize a Massachusetts earthquake, it is more than enough for the purpose of this

thesis. The site classes in Massachusetts and California are both C (IBC 2012 - Table

1613.5.2), since soil conditions are average to poor.

The west coast earthquake used in our time history analysis is from Altadena Eaton Canyon Park (Los Angeles County, California). This particular region in the south

of California is known for their frequent earthquakes (magnitude 5.0 and up). A step by

step procedure on how we scaled down our earthquake can be found in "Chapter 4:

SAP2000 Model" of this thesis.

The next table summarizes all loads with their orientation in which they will be

analysed plus their pounds per square foot value as well as their distributed load value.

Load

Orientation

D

4

L

4

Lr

4

S

4

W (roof)

4

W (windward)

E

Value

Distributed Load

Self-weight + 37 psf Self-weight + 0.74 kip/ft

125 psf

2.5 kips/ft

20 psf

0.4 kip/ft

30 psf

0.6 kip/ft

38 psf

0.76 kip/ft

35 psf

0.7 kip/ft

Dynamic Analysis

Table 1 - Loads Summary

As mentioned earlier, LRFD load combinations will be used in all of our analyses.

Every load case is presented below in Table 2. For cases 3c, 3d, 4a, 4b and 6a, lateral

wind loading will be analysed in both directions. The same will be done in our time

history analysis with the earthquake loading cases 5a, 5b, 7a and 7b in order to obtain a

force envelope.

17

Case

1 a

2a

Combination

b

a 1.2D + 1.6Lr + L*

3

b

4

a

b

c

d

1.21D + 1.6S + L*

1.2D + 1.6L + 0.5W

1.2D + 1.6S + 0.5W

a

5

b

6

a

7

a

b

Table 2 - Load Combinations

Following ASCE 7-10, L* will be taken as L instead of 0.5L, since L is greater

than 100 psf. The sketch below shows all dimensions of our typical frame with the

location of every load. The next step involves on defining our bracing schemes.

D, Lr, S & W

f

I

I

I1

I

I

I

I

I

I

I

I

D&L

4 @ 20'

D&L

/

MMMMWI

3 @ 25'

Figure 3 - Typical Frame Overview

18

CHAPTER 3: BRACING CONFIGURATIONS

To counter lateral loads, our typical frame needs a bracing system. We came up

with nine different configurations of bracing. The first bracing configuration is copied

from the original structural plan of the building and consists of multiple traditional xbracings. The second, third and fourth configurations are also x-bracings but in a

different pattern.

The fifth, sixth and seventh configurations are similar to previous patterns but

with chevron bracings instead of x-bracings. The eighth configuration is quite simple

and made of four single braces. Our last configuration is a mix between v-bracings and

chevron bracings. All bracing configurations can be found below on figures 4 to12.

Those bracing configurations are really common lateral systems and mainly used

in tall buildings. All brace members are going to be 2L6x6x3/8 (double angles back to

back) as per structural plans. Now that we have our bracing configurations, we can

model our braced frames in SAP2000.

Figure 4 - Typical Frame

Figure 5 - Bracing Configuration 1

19

Figure 6 - Bracing Configuration 2

Figure 7 - Bracing Configuration 3

Figure 8 - Bracing Configuration 4

Figure 9 - Bracing Configuration 5

Figure 10 - Bracing Configuration 6

Figure 11 - Bracing Configuration 7

20

Figure 12 - Bracing Configuration 8

Figure 13 - Bracing Configuration 9

21

CHAPTER 4: SAP2000 MODEL

4.1 BUILDING THE MODEL

Our frame will be modeled in 2D (XZ plan). Column members are defined as

W1 8x1 19 while girders are W1 6x40 sections. Numbering is an important issue here and

need to be the same for all braced frames. The following figure shows the numbering of

each horizontal member and nodes.

Figure 14 - Members & Nodes Numbering

Next, we restrain our columns by completely fixing them at their base (no rotation

and translation allowed). We then define our load patterns (D, L, Lr, S, W and E) and

apply them to the frame. The last step in building our model would be to input our load

combinations defined earlier.

22

4.2 MASSACHUSETTS EARTHQUAKE SCALING

To scale down our California earthquake to a standard Massachusetts quake for

our time history analysis, we will compare both frames under static earthquake loading

and do a ratio of their maximum displacements. We start be defining two response

spectrum functions (with the IBC 2006, SAP2000 integrated code) for both Altadena &

Massachusetts areas. To do that, we need both respective zip codes and site classes in

order to have adequate properties of our earthquakes. We will assume a 0.05 (5%)

damping ratio in our typical frame.

Figure 15 - Altadena Response Spectrum Proprieties

23

Figure 16 - Massachusetts Response Spectrum Proprieties

Once we have two appropriate response spectrum functions, we need to define

them as a load case type to our earthquake load patterns (QUAKE 2 & 3 in the figure

below). Note that the load pattern QUAKE will be used as a time history load case

defined in the next section of this chapter.

Caset

-Load

-

Ctkx

LoadCaseName

Load

Cae Type

DEAD

Linew

Static

MODAL

Modal

LIVE

LinesStaic

RlOOF

LIVE

LinesStaic

--

AddNewLoadCaa..

Add Cm ofLoad Cam~..

ModyShow LoadCam..

Date

LoadCase

Display

LoadCasesQUAKE3

Repons-S

ShowLoadCaseTee..

OK

Cancel

I

Figure 17 - Assign Load Case Type to the Earthquake Load

24

Running an analysis for both static earthquakes, we find the nodes with the

maximum displacement and do a ratio between them. For the Altadena earthquake, the

maximum displacement is 0.0011 foot while for the Massachusetts earthquake, it's

0.0001 foot. The ratio between both displacements equals:

Scale factor =

=

0.0001

umaxMA

-

Umax cA

0.001

0.0011

=

0.0909

In our time history analysis, we will scale down our California earthquake by this

factor in order to have more realistic results. The next two figures (18 & 19) show the

deformed shape of our frame under the static earthquake loading with their maximum

displacement in the x-direction (circled in red).

Figure 18 - Max. Displacement (Altadena Static Quake)

25

Figure 19 - Max. Displacement (Massachusetts Static Quake)

4.3 TIME HISTORY ANALYSIS DETAIL

To create a dynamic earthquake in SAP2000, we have to use a time history

function. This function is defined from a .th (extension type) file built-in SAP2000's

database. We have multiple choices of earthquake accelerograms to choose from and

luckily for us, Altadena earthquake is one of them! Using those accelerogram values

spaced equally at an interval of 0.02 second we can define our function (see figure 20).

Next, we need to modify our load case type QUAKE (Linear Modal History) with

the appropriate scale factor. Note that accelerogram values are in cm/s 2 , and all of our

loads are in kips/ft. To have suitable results, we need to multiple our scale factor by

0.0328ft/cm. The final scale factor to be used is equal to 0.00298 (shown in figure 21).

26

ITIMEHISTORY

Function Name

Values am

Function Fie

Browse.

Fie Name

amx8)\ompuAes and

ltimei history

14\__

Header

Unes toSkip

Tine and Function Values

r

Values atEquallntrvals of

Format

--r* FreeFormat

|3

C

PrefiCheractas perLinetoSkip |0

Nwmer ofPoints

perLine

C

1002

-T

Fused

Format

I

Characters

perItem

|8

Convt to Uw Defined

ViewFie

Functisn

Graph

I

DisplaGraph

I

o.,AO

Figure 20 - Time History Function

Load

Case

--

SetD Nae

QUAKE

Load

Cue Type

Notes

ModyiShow..

Inital Condiins

State

ro Zeo Iriial Concins -Stat fromUnstressed

C

Canoe ha

Ed fMod

[e

TimeHistory

Desir

Anah*jsss

Typ

$ Liaer

-TUeHistryType

ro Modal

j

H o

Important

Note: Loadsfromthis

previous

casearenckuded

in the

T Hory Mao Typ e

TiunHistoryMotion Type

ctart case

- -Transient

IMODAL

UseModesfromCse

LoadType

LoadName

LoadPatte7rIQUAKE

Furction

JTIMEHISTO

ScaleFactor

0.002981818

-Add

rTine

Delete

~ ShowAdvancedLoadParameters

Step

Data

Nure ofOutputTimeSteps

100

Oupot TimeStopSi.

101

Pmetees

rOther

ModMDameprig

-

at 0.05

Constant

-

MoyShow..

Figure 21 - Apply the Scale Factor to the Load Case

27

This time history analysis will give us a force envelope for each member, which

represent the maximum and minimum axial forces in the member for the total duration

of the earthquake. On the next figure, we can see the force envelopes for an

earthquake created with a time history function (bracing configuration 4).

Figure 22 - Example of Force Envelopes Under a Dynamic Earthquake

The last step is to add every other bracing configuration (bracing members are

2L6x6x3/8) to the model and run multiple analyses to find the axial force in all horizontal

members, for each load combination. Once we have those forces, we can now

determine the pass through force at a joint. The next section of this thesis shows how

we determined the absolute maximum PTF at all joints for our nine braced frames.

28

CHAPTER

5: RESULTS

First thing we needed to do was to export the values from SAP2000 to Excel.

Once we exported all those values for every load combination, we could use a Pivot

Chart in Excel to find the maximum and/or minimum axial forces in every member. The

following chart (Table 3) is an example for the first bracing configuration. The members

are numbered the same way mentioned earlier (see figure 14 and/or figure 23 at the

end of this chapter).

Axial

MAxubera

a

OMB2a

OMB2b

OMB3a

OMB3b

OMB3c

OMB3d

OMB4a

OMB4b

Axial

ber #

OMB3c

OMB3d

OMB4a

l.COMB4b

OMB6a

17

-4178

.751

9.018

-8.186

9.039

9.207

10.06

-14.851

15.118

10.525

18

-91

-8.967

-9.009

-6.667

-6.8

-3.9

-4.033

-9228

-9.27

-4.44

17

18

334'Tr

4248 -1.605

3.226 -4.373

-4.414

1.1

0.416

1-3.493

19

IM

-8.827

-8.936

-7.113

-7.465

-4.329

-4.68

-8.385

-8.495

-3.816

19

-3.76

-6.544

-6.654

-1.975

Axial Load (kips)

20

21

22

23

1.66

5-901

SM

-060

-4.241

7.924 6.273 -0.302

-3.934

8.353 6.655 -0.352

-0.535

9.055 7.572 -0.642

0.447

10.425 8.797 -0.802

-3.121

6.482 7.541 -7.756

-2.14

7.853 8.766 -7.917

-14.911 4.538

7.109 -14.252

-14.605 4.966

7.492 -14.303

-11.955 111

4.582 -14221

20

13.219

15.805

16.112

1861

Earthquake

Meber #

17

18

Enve

Max

Min

Max

Min

COMB&e

.5Z

-652--2

COMB5b

-6.098 -7.456 -5.959 -6.91

ICOMB7a

-2.029 -3.387 -1235 -2.186

ICOMB7b

1.985 1-3.343 -1.204 -2.156

LI

Member #

nve

OMB5

OMB5b

OMB7a

OMBib

23

Max

.093

.127

.084

.119

Min

-0.889

-0.854

-0.898

-0.863

Axial Load (kips)

22

23

24

.9

TMTW

13.74

10.454 5.534

15.414

16.312 10A85 12.648 28.826

116.74

10.868 12.598 .29.118

12.935 7.968 12679 14.583

21

Min

19.614

19.667

5.605

5.658

25

5.54

14.829

14.992

11.921

12.441

6.457

6.977

12.355

12.518

4.1

26

rgl

18.951

19.048

14.161

14.47

4.744

5.053

12.288

12.384

2.19

25

26

.2

7.063 7.235

12.527 16.652

12.69 16.749

4.953 6.554

Axial Load (kips)

19

20

21

Max

Min

Max

Min

Max

Min

-313771

=

-6.52

-6.562 -1.157

-3.034 7.413 6.286

-2.04

-2.081 1.976

0.099 4.336 3.209

-2.039 -2.081 2.045

0.167 4.378 3251

25

Max

21.112

21.165

17.103

7.156

24

ME

27.543

27.835

21.91

22.845

8.498

9.433

16.864

17.156

1

Max

Min

11.6

10.339

11.813 10286

4.422 2.895

4.368 2.841

26

Max

15.

15.658

5.775

5.637

Min

11.659

11.521

1.638

1.5

27

28

0"W90.

1.239 31.374

1.265 31.569

1.135 23.986

122

24.61

1.778

10.471

1.863

11.095

3.038 23.586

3.064 23.781

7

27

00

0.045

-0.598

-0.571

-1167

Min

-0135

-0.859

-1.283

-1.407

12.119

25.633

25.828

9251

22

Max

1r

5.629

3.401

3.408

27

Max

2.854

2.73

2.306

2.182

28

Min

5.541

3.313

3.32

2

Max

Min

23.14

22.795

23.149 22.803

6.914 6.569

6.922 6.577

I

Table 3 - Axial Forces in Members (Bracing Configuration 1)

This last table is divided into three parts; the first part is for static load

combinations with the lateral wind load taken in the positive direction; the second part is

29

for the wind load in the opposite orientation, while the last part is the axial force

envelopes (max. and min.) for the dynamic load combinations (earthquake load). All

other charts for every bracing configuration can be found in Appendix A.

Knowing the axial loads in every member for each load combination, we are now

able to find the PTF at any node. First, we won't analyse the exterior nodes and

concentrate our study on the interior ones only (node # 2, 3, 6, 7, 10, 11, 14 & 15). This

is simply because there is no PTF at those joints. The PTF for every static load

combination was calculate as follows:

PTFnode = abs(FAL - FAR)

where:

PTFoode=

Pass Through Force at the node

FAL =

Axial Load in the Member Left to the Node

FAR=

Axial Load in the Member Right to the Node

For example, the PTF at node 2 for the load combination 1a is the difference between

the axial loads in members 17 & 18 of the same load combination. Note that we took the

absolute value to be conservative and because the frame could be mirrored. For the

dynamic load combinations, we took the maximum absolute value of the difference

between the axial load envelopes of each member on each side of the node.

Table 4 shows the PTF at every node for all load combinations as well as the

maximum calculated values for the first bracing configuration. Tables 5 through 12

summarize the maximum value of the PTFs for each bracing configuration. Detailed

calculations of each case can be found in Appendix B.

30

Axial (+W)

PTF (± kips)

Node #

COMBIa

COMB2a

COMB2b

COMB3a

COMB3b

COMB3c

COMB3d

COMB4a

COMB4b

COMB6a

2

1.541

0.216

0.009

1.519

2.239

5.307

6.027

5.623

5.848

6.085

Axial

Node#

COMB3c

COMB3d

COMB4a

COMB4b

COMB6a

PTF (± kips)

2

3

6

7

10

1.922 1.936 0.132 3.139 8.785

2.643 2.155 0.521 3.286 9.88

1.147 2.171 0.507 5.827 16.18

0.921 2.24 0.628 5.872 16.52

0.684 2.391 5.826 4.977 1.904

3

0.568

0.14

0.073

0.446

0.665

0.429

0.647

0.843

0.775

0.624

6

4.234

12.17

1229

9.59

9.978

9.603

9.993

19.45

19.57

13.12

10

10.53

27.85

28.19

22.55

23.65

1625

17.35

31.12

31.46

16.84

11

14

15

4.276 4.959 9.794

1271 17.71 30.14

12.84 17.78 30.3

9.989 13.03 22.85

10.4

13.25 23.39

2.041 2.966 8.693

2456 3.19

9.232

4.509 925 20.55

4.638 9.32 20.72

2.16

0278 4.736

-

Earthquake

Node.#

COMB5a

COMB5b

COMB7a

COMB7b

7

0.673

1.651

1.698

1.483

1.628

1.059

0.913

2.571

2.526

3.421

11

14

7.936 6.966

8.351 7.19

16.3

17.25

16.43 17.32

9.63

7.721

15

11.54

12.07

26.23

26.4

10.42

PTF (± kips)

2

1.51

1.497

2.152

2.139

3

6

0.572 10.47

0.603 10.45

0.846 4.237

0.877 4.211

7

1.837

1.872

1.023

1.058

10

11

14

15

22

10.77 16.53 23.88

22.02 10.88 16.52 24.01

8.001 4.208 7.058 8.197

8.019 4.315 7.044 8.329

I

PTF (± kips)

-

-

I

2 | 3 | 6 1 7 | 10 1 11 1 14 1 1s

.085 12.391 119.57 15.872 131.46 116.43 17.78 3I3

Table 4 - PTFs (Bracing Configuration 1)

Table 4 is divided into three parts (exactly like the precedent table) plus a fourth

part showing the maximum PTF at every node.

31

i

PTF (t kips)

2

3

6

15.29322.08

8.08

7

10

114.99 136.25

11

32.19

14

21

15

21

Table 5 - PTFs (Bracing Configuration 2)

PTF (t kips)

Table 6 - PTFs (Bracing Configuration 3)

PTF (t kips)

RA

F8.056 4-89

122-89

I

119-27 1118 19-16 135.46 1.384

Table 7 - PTFs (Bracing Configuration 4)

t 10-82

z

I110.92

14

126-2b

I I

I127186

1IU 127

125-89

Table 8 - PTFs (Bracing Configuration 5)

PTF ft kinsa

uoa0 I

I8.051

18.199 125-54 124.4

z

4

la

19127-88 13.4 125.02 1

Table 9 - PTFs (Bracing Configuration 6)

PTF (t kips)

[NodelI

MAX

2

12.21

3

12.41

6

7

18.97 20.21

I

10

11

14

15

35.06 20.82 3612 2.591

Table 10 - PTFs (Bracing Configuration 7)

32

PTF (tkips)

Node 8

MAX

2

J5.331

3

6.206

6

7

10

11

14

15

114.76 120.49 113.05 13.202 146.54 12.652

Table 11 - PTFs (Bracing Configuration 8)

2

M725

PTF kips)

3

6

7

10

11

14

15

13-25 18.165 17-711 145-79 145-79 110-111 111100-111Ij

Table 12 - PTFs (Bracing Configuration 9)

Figure 23 - Reminder of Members & Nodes Numbering

In the next chapter of this thesis, we will analyse each case as well as comparing

our results with 2 different methods.

33

CHAPTER

6: ANALYSIS & COMPARISON

6.1 ANALYSIS

By looking at every PTF we calculated in the previous chapter, we can see that

for every bracing configuration, PTFs at the top nodes (#2 & 3) are pretty small. This is

mainly due to the load path taken by the load from the top to the bottom of the frame. A

PTF will occur when the force in the bracing need to take a horizontal path instead of

going directly to the ground. Since there is no bracing above the top nodes, no force is

added to the members. Actually, PTFs at the top nodes are due to the fact that lateral

forces go directly into the diagonal bracing (following the load path to the ground), which

reduce the axial load in the members. Usually, PTFs less than 10 kips are not a big

issue and barely affect the design of the steel connection.

6.1.1 BRACING CONFIGURA TION 1

X 0k

+.3k

±9.57

±.87

±1.46

±6.43

±17.78k

±30.30k

Figure 24 - PTFs Sketch (Bracing Configuration 1)

For the first bracing configuration, we can see that critical PTFs happen at nodes

where bracings are non-symmetrical (nodes 6, 10 & 15). If bracings are symmetrical,

34

the force follows the load path to the ground by transferring the majority of its force to

the opposite bracing instead of going in the horizontal member. Maximum PTFs are

located at nodes 10 (±31.46 kips) and 15 (±30.30 kips). Because bracings are not

symmetrical at those locations, the forces will follow a different path to the ground,

resulting in PTFs.

6.1.2 BRACING CONFIGURA TION 2

220&.08k

+14.99k

16.25

±2.1

±21.00k

+21.00k

Figure 25 - PTFs Sketch (Bracing Configuration 2)

Again, for this bracing configuration, PTFs have a higher value at nodes where

the bracing isn't symmetric. Critical values can be found at nodes 10 (±36.25 kips) and

11 (±32.19 kips). Forces follow the load path from the top of the building to the bottom

(through bracings & columns) and when they arrive at those nodes, the unsymmetrical

pattern of the bracing forces them to take a different path. Since the force has been

built-up from the top (accumulation of lateral and gravity loads), the PTFs at those

locations are the highest. We can also see that PTFs are smaller near the bottom, since

forces go directly from one bracing to the other due to the symmetry in the brace

configuration at those nodes.

35

6.1.3 BRACING CONFIGURATION 3

Figure 26 - PTFs Sketch (Bracing Configuration 3)

Like the previous bracing configuration, the highest values of PTFs are where the

bracing scheme is non-symmetric. In this case, near the bottom of our frame we find the

maximum values of PTFs.

6.1.4 BRACING CONFIGURATION 4

Figure 27 - PTFs Sketch (Bracing Configuration 4)

36

Here is a good example to prove our point that node where bracings are

symmetric introduces less PTFs. Nodes 10 (± 11.18 kips) and 15 (±1.38 kip) have a

bracing scheme symmetric and missing respectively. Those two nodes have less PTFs

than others (expect for the top nodes). Again, the maximum PTF is at the bottom, at

node 14 (±35.46 kips). The next bracing configurations will be a little bit different by

changing the x-bracing scheme to chevron braces.

6.1.5 BRACING CONFIGURATION

5

±0.82

±26.20k

±7.86

±20.25k

+0.92

+25.89k

+7.85

±20.25k

Figure 28 - PTFs Sketch (Bracing Configuration 5)

The next three bracing configurations are chevron braces which follow a quite

different pattern if we compare with x-bracings. PTFs are generally smaller in a chevron

brace configuration since loads tend to follow a direct path to the ground. In the case of

a chevron, nodes don't have any symmetry relative to bracings. PTFs are mainly the

result of the horizontal component of the force in the brace, and in the case of a

symmetric frame (like we have here), PTFs will be similar at each storey. PTFs at the

bottom are smaller since forces follow the shortest path to the ground. An interesting

37

comparison can be done with the second bracing configuration, where PTFs were

greater near the bottom and higher in general. Chevron brace schemes reduce PTFs at

nodes since bracing take less axial loads (forces go mainly in columns).

6.1.6 BRACING CONFIGURA TION 6

Figure 29 - PTFs Sketch (Bracing Configuration 6)

Here again, we notice the same pattern as the previous bracing configuration,

where PTFs are similar at each floor and tend to be smaller at the bottom. Globally,

PTFs are smaller if we compare with the third bracing configuration.

6.1.7 BRACING CONFIGURATION 7

Figure 30 - PTFs Sketch (Bracing Configuration 7)

38

Due to the asymmetry of this bracing configuration, PTFs at each floor aren't the

same. Again, where there is no bracing, the PTF is none. The main PTFs are located at

the nodes where bracing frames in (nodes 10 & 14) and if we compare with the fourth

bracing configuration, PTFs seem to be higher. This could be due to the load path

forces are taking. Bracings on the left-side take much more loads. This bracing

configuration demonstrates the load path being less distributed in the frame and

columns and more concentrate toward braces. This results in more PTFs at the nodes.

6.1.8 BRACING CONFIGURATION 8

±5.33k

+6.21k

±14.76k

+20.49k

±13.05k

±3.20k

±46.54k

+2.65k

Figure 31 - PTFs Sketch (Bracing Configuration 8)

This bracing configuration is quite similar to the fourth configuration except there

are two nodes without any bracing which outcomes small values of PTF. We can see

that where bracings are symmetric (node 10), the PTF is small as well. The bracing

which takes the most axial loads is the one at the bottom left, and as a result, creates a

high value for the PTF in node 14 (±46.54 kips). Since there is less bracings in this

configuration, diagonal members tend to take more loads.

39

6.1.9 BRACING CONFIGURATION 9

Figure 32 - PTFs Sketch (Bracing Configuration 9)

This last bracing configuration is kind of a mix of every other configuration. We

have nodes with symmetry (6 & 7), as well as nodes with uneven symmetry (10 & 11)

and nodes without brace (13 & 14). At nodes 6 & 7, the force doesn't have the chance

to go from one horizontal member to the other, since it goes in the bracing instead. This

results in small PTF at those locations. Because of the non-symmetry of nodes 10 & 11,

huge PTFs are generated. Also axial load from center bracings of the third floor add

more axial loads in the horizontal member below, which result in more PTFs at those

nodes. As always, nodes 13 & 14, where no bracing is framing, have less PTF. As a

reminder, because the horizontal component of the axial force in the brace is missing

(absent brace) fewer axial loads are carried through the node.

6.2 COMPARISON

In this section, we will compare our results with two traditional ways of calculating

PTFs. The first method consists of calculating the PTF with the maximum values of axial

40

forces in the member (its design value). The second one is more conservative and take

the PTF equals to the total axial loading in the bracing.

6.2.1

1ST METHOD

As mentioned earlier, this method consists of taking the design axial load in both

girders on each side of the node and do the difference between those forces to get the

actual PTF. Doing so, we will need to find the maximum design axial load in each

member using the tables in Appendix A. Once we have those design values, we can

compute the PTFs with the same formula used earlier (see chapter 5). The big

difference of this method is that we calculate only one value of PTF at each node using

the design axial force of the members instead of calculating PTFs for every load

combination and take the maximum of them.

Using the first bracing configuration as an example, we first determine the

maximum (tension) and minimum (compression) values of axial load in the members.

The absolute maximum value from the table below is the design axial force (in kips) of

the member.

ber#

Max

17

1.1

15.118

15.118

18

0.416

-9.27

9.27

19

-1.975

-8.936

8.936

20

18.761

-14.911

18.761

21

16.74

1.161

16.74

22

23

10.868 12.679

3.313 -14.303

10.868 14.303

24

25

26

29.118 14.992 19.048

2.621 2.841 1.5

29.118 14.992 19.048

27

3.064

-1.407

3.064

28

31.569

6.569

31.569

Table 13 - Design Axial Force of Members (Bracing Configuration 1)

We are then able to compute the PTF (in kips) at each node and compare those

values with the results we found. The last row of Table 14 indicates if the PTF

calculated with the

1 st

method is bigger than the one computed earlier. "NG" stands for

"No Good".

41

Node#

PTF

K?

2

5.848

NG

3

0.334

NG

6

2.021

NG

7

5.872

NG

10

14.815

NG

11

14

14.126 15.984

NG

NG

15

28.505

NG

Table 14 - Comparison of PTFs using the 1st Method (Bracing Configuration 1)

Looking at the results in Appendix C for this 1s' method for all bracing

configurations, we find something interesting.

The PTFs calculated with the design

value of axial force in the members is ALWAYS smaller than what we've computed

earlier. This means that if we design a connection using the 1st method, we will probably

underestimate the value of PTF, which could result in a failure. It is safer to compute

PTFs for every load combination and then take the maximum value.

6.2.2 2ND METHOD

For this second method, we will compare the design axial load in the diagonal

members with our PTFs calculated in chapter 5. This method was used in real life for

the first bracing configuration (Colonsay Project). We will only analyse the first bracing

configuration for this method. First thing we need to do is number each brace.

Figure 33 - Bracing Numbering (Bracing Configuration 1)

42

Using a similar approach with our SAP2000 results, we are able to find the

design axial load in each diagonal member (in kips). Notice that the absolute maximum

value of axial force in every brace is generated by compression (the absolute of the

minimum value in Table 15 always governs). Detailed calculations for the axial force in

bracings can be found in Appendix D.

#

29

-749

30

43

44

38

35

40

41

42

34

35

36

37

33

861

-518.676

7.697

-3

2.9 4 I.

23 57 10.75

-2.624

2.-593

-14.9

-1.317.192

-10.141 -4.005 -14.918 -16.317 -18.676 -7.697 -30.95 -43.435 -28.788 -10.75 -28.502 -66.785 -59.387 -20

'10.141 4.005

'14.918 '16.317 '18676 7697

30.95

'43435 '28.788 '10.745' 5M WM~Y

6.8

59.7 2

31

32

-8.351 -0.1 -0

M-7.479 -8.662

Max 7.479 86

Table 15 - Full Axial Force in Diagonal Members (Bracing Configuration 1)

Since PTFs are usually generated by the transfer of load from a bracing to

another, we will do a force equilibrium at each node using the forces in the diagonal

members (see Table 15). For example, the next figure illustrates the forces at node #15

(surrounded by bracings #37, 40 & 43):

10.75k

30.95k

0 =38.66*

Node 15

59.39k

Figure 34 - Force Equilibrium at node 11 (Bracing Configuration 1)

A conservative way of doing this is to assume 8 equals to zero. The PTF will be

the sum of the full axial force in the bracing. Table 16 displays the value of PTF at each

node using the

2 nd

comparative method.

43

PTF (± kips)

Node #

MAX

OK?

2

7.479

OK

6

7

10

11

3

23.58

1.115

47.267

21.868

1.479

OK

OK

NG

NG

OK

Table 16 - PTFs 2nd Method using 0 = 0"

14

23.35

OK

15

39.18

OK

If we take the real value of 0 (38.660) and take the horizontal component of the

bracing force instead of its full value, we obtain the PTFs in the table below (Table 17).

In real life, they usually take 0 equals to zero, but can we lower PTFs' values in order to

save money in the connection design?

PTF (± kips)

Node #

MAX

OK?

2

5.84

NG

7

10

11

3

6

0.871

36.909

17.076

1.155 18.413

OK

NG

OK

NG

NG

Table 17 - PTFs 2nd Method using 0 = 38.66*

Comparing results of the

2 nd

14

18.233

OK

15

30.6

OK

method with the values calculated in chapter 5 gives

us interesting results. As a reminder, Table 18 shows the calculated PTFs (as per

chapter 5) for the first bracing configuration. Starting with the case where 0 is equals to

zero, PTFs are relatively conservative except for node 3 & 7. Since those two nodes

don't see a lot of PTFs (one node is at the top, the other is surrounded by symmetrical

bracing) we can assume that it's a realistic and conservative way of computing PTFs.

PTF ( kips)

INode#

14

15

11

10

6

1 7

3

2

17.783 30.3

5.872 31.459 16.428

6.085 2.391 19.571

MAX

Table 18 - Reminder of PTFs Calculated for the First Bracing Configuration in Ch. 5

Taking the horizontal component of the bracing force instead of its full value

Fh = F - cos(6)

44

results in similar PTF at the node. We can see that PTFs at node 2, 3 & 7 are still

smaller than the PTFs calculated in chapter 5. As mentioned earlier, top nodes and

nodes with symmetrical bracing don't really cause a problem, since PTFs are generally

small. For this case, we need to be careful because at node 6 (an asymmetrical node),

the value of PTF is also smaller. Even if the difference is less than 10% (a little bit less

than 6% to be accurate), it could be problematic. Using a conservative method by taking

the angle equals to zero is probably the best way of obtaining adequate results if you

decide to use the

2 nd

alternate method.

Following our analysis and comparison, the best way of obtaining the PTF at a

node is to look at every load combination in detail. This means to find the maximum

axial force in all members and compute the PTF at the joint for each load combination.

Then take the maximum PTF of all load combinations to obtain the value to use in the

steel connection design.

Using those steps to calculate the PTF will result in the cheapest and safest way

of designing steel connections. The first method shouldn't be use at all while the second

could be used but with caution and good judgement. If you don't know the PTF at a

node and need to design a steel connection, the best alternative would be to use the

second method with an angle equals to zero, since it is the most conservative and less

time consuming.

6.3 MOVING FORWARD

Now that we understand a little bit more where pass through forces come from,

we could try to come up with a model for plan instead of elevation. PTFs can also be

found in plan view as part of the lateral system. A similar model could be done to see if

45

results concord. The next step would be to create a 3D model and find PTFs in all

directions at a node. Sometime, connection designs can be tricky and the more

accurate your design loads are, the more money you will save designing your

connections. The next figure shows the complexity of some connections and how

important it is to minimise the steel used in your connection. Overdesigned connections

can increase the total cost of your building by a huge factor.

Figure 35 - Complex Steel Connection 2

Thanks to ADF Group Inc. (Fabricator of Complex Structural Steel and Heavy Built-Up Steel Components) for

letting me use this picture in my thesis!

2

46

CHAPTER 7: CONCLUSION

Looking back at our results, we learned interesting facts about pass through

forces. We first defined our static loads using the ASCE 7-10 as well as IBC 2012 codes

and then scaled down a California earthquake to represent the magnitude of a

Massachusetts quake so we could do a dynamic time history analysis. Using an existing

braced frame and common bracing configurations, we have created multiple models in

SAP2000 to analyse.

Exporting axial loads from SAP2000 to Excel and then using a Pivot Chart to find

the maximum and minimum forces for each member of all load combinations of every

bracing configuration was necessary to obtain accurate values of pass through forces.

Then, knowing the axial force in each member on both sides of a node, we were able to

calculate the pass through force at that node for each load combination. The maximum

of those pass through forces was used to analyse each bracing scheme.

Comparing each bracing configuration's result, we learned that top nodes and

nodes with symmetrical bracing carry fewer pass through force. This is due to the load

path forces take from the top of the frame to the ground. If the force is able to transfer

directly to the opposite bracing instead of going in the horizontal member, fewer pass

through force will occur. Nodes without bracing have small value of pass through force,

while nodes with asymmetric bracings are more subject to pass through force.

Next, we compared our results with two traditional methods of computing pass

through forces. The first one consists of taking the design axial force of each member to

47

calculate the pass through force at the joint. This method underestimates pass through

forces and shouldn't be use. The second method is quite conservative and requires

doing a force equilibrium at the node with the full or horizontal component of the force in

the bracing. This second method needs to be used with caution in order to obtain

accurate results.

The following step would be to expand our model to horizontal bracings on a plan

view and see if we obtain concurring results. A 3D model could also be done to really

understand in depth the pass through force phenomenon. Buildings getting taller every

year, lateral systems take more axial loads which create larger values of pass through

forces. Fully understand pass through forces will result in cost savings for steel

connection design.

48

REFERENCES

BOOK

+ Minimum Design Loads for Buildings and Other Structures. Reston, VA:

American Society of Civil Engineers, 2010. Print.

+

2012 International Building Code. Country Club Hills, IL: ICC, 2012. Print.

** Steel Construction Manual Fourteenth Edition. American Institute of Steel

Construction, 2011. Print

* McCormac, Jack C. Structural Steel Design Fifth Edition. New York: Harper &

Row, 1981. Print.

+

Green, P.S., Sputo, T., and Veltri, P. (n.d.) Connections Teaching Toolkit -A

Teaching Guide for Structural Steel Connections. American Institute of Steel

Construction, Inc. Chicago, IL. Print

*

Thornton, William A. "Connections: Art, Science, and Information in the Quest for

Economy and Safety." Engineering Journal Vol. 32, No. 4 (1995). Print.

WEBSITE

+

"Department of Civil and Environmental Engineering." MIT EECS. Web. 22 Mar.

2012. <http://www.eecs.mit.edu/ug/thesis-guide.html>.

+

Earthquake Engineering Research Center, (EERC). (1997). W.G. Gooden

Structural Engineering Slide Library. Godden J1 19. Web, 25 Mar 2012.

<http://nisee.berkeley.edu/bertero/htmI/recentdevelopmentsjin_seismic-design

_andconstruction.html>.

49

+

Sigi Engineering. Connections and Bracing Configurations. Web PDF. 25 Mar.

2012. < http://www.sigi.ca/engineering/civl331_2010/connectionsbracing.pdf>.

* "Computers and Structures, Inc." Computers and Structures, Inc. Web. 25 Mar.

2012. <http://www.csiberkeley.com/>.

*

"Altadena Earthquake Information." Altadena Los Angeles County California

Earthquake History and Probability Risk Grade. Web. 26 Mar. 2012.

<http://www. homefacts.com/earthquakes/California/Los-AngelesCounty/Altadena.html>.

+

Office of Construction & Facilities Management. Seismic Design Requirements.

H-1 8-8. Department of Veterans Affairs. Web PDF. 28 Mar. 2012.

<http://www.wbdg.org/ccbNA/VASEISMC/seism ic. pdf>.

+

"Time History Analysis With Recorded Accelerograms." Upload & Share

PowerPoint Presentations and Documents. Web. 2 Apr. 2012.

<http://www.slideshare.net/alexpalm/time-history-analysis-with-recordedaccelerograms>.

4+ "DPHV's Firm Profile." Accuel. Web. 2 Feb. 2012.

<http://dphv.ca/pages/dphv-profile.htm>.

C+ "ADF Group Inc." Fabrication of Complex Structural Steel and Heavy Built-Up

Steel Components. Web. 28 Apr. 2012.

<http://www.adfgroup.com/en/home.html>.

PROGRAM

+e Computers & Structures, Inc. (CSI) - SAP2000 v14

.+ Microsoft Office - Excel 2010

50

APPENDIX

A: AXIAL FORCES IN MEMBERS

Frame 0

Axial (+W)

Member #

Ba

OMB2a

OMB2b

OMB3a

OMB3b

OMB3c

OMB3d

OMB4a

COMB4b

Axial 1-W)

rembr

#

OM13d

OMB=

OMB4a

OMB4b

OMB6a

17

18

7-.

'

.

9.826

-23.074

-10.097 -23.314

-8.977

-18.112

-18.882

-9.842

-9.566

-10.513

-10.431 -11.283

15.762 -21.923

-16.032 -22.163

O10.861 -9773

17

.512

3.923

.193

0.978

-8.242

-15.842

-16.082

-3.692

Min

8.125

7.767

0.656

0.299

Axial Load (kips)

21

22

23

24

.M

.1

.IM -T.

-30.839 -25.13 31.852 -13.64

-30.803 -24.93 32.181

-13.61

25.076 -9.311

-21.325 -16.1

-21.209 -15.48 26.129 -9.201

-7.727 -2.984 7.284

-2.796

-7.612 -2.355 8.337

-2.686

-25.472 -17.92 15.457 -10.36

-25.436 -17.73 15.786 -10.33

1-3.77 -1.223 1-2.824

31.852

32.181

25.076

26.129

11.63

12.683

24.148

24.478

7468

Axial Load (kips)

22

23

25

20

21

-7.455

-9.809

-10.08

-4.908

5.07 1.1-3.072

-2.875

11.073

-0.414

-11.076

-11.04

5.935

18

Max

-1.

Min

-

-16.86 -16.861

-4.904 4904

-4.904 |-4.904

23

Max

4.147

4.264

.73

.847

20

.W

-25.126

-24.929

-16.103

-15.475

-7.962

-7.333

-27.877

-27.681

-13.733

19

18

Earthquake

17

ember #

nye

Max

Min

.

OMB5a

OMB5b

.774 -8.26

OMB7a

2.197 -3.682

COMB7b

-2.09

1-3.575

Member #

n

OMB5e

OMB5b

OMB7a

OMB7b

19

-4.4R

-9.826

-10.1

-8.977

-9.842

-6.623

-7.488

-9.875

-10.15

-4.974

3.682

2.375

2.41

9.912

14.664

28.11

28.439

11.43

Axial Load (kips)

19

20

Min

Max

Min

Max

Max

Min

-12.156

-12.156

-4.592

-4.592

19.009

36.801

37.13

20.121

1.

.

-6.882 -8.367 -17.038

-2.09

-3.575 -2.727

-2.197 |-3.682 1-2.737

25

24

Max

-6.825

-6.825

0.74

0.74

0.092

-13.03

-12.83

1.117

24

25

Max

24.264

24.147

7.847

7.73

Min

7.767

8.125

0.299

0.656

26

Min

Max

11.229 0.412

11.181 0.444

3.305

0.041

3.257 -10.073

26

7.982

16.74

16.857

13.444

28

.45

15.082

15.199

11.527

11.903

3.174

3.55

7.876

7.993

0.011

28

27

7.511

15.835

15.948

8.084

21

-1.1-1.

-17.22

-2.91

|-2.92

26

27

4.6.

4

4

15.082 14.556

15.199 14.669

11.527 11.11

11.903 11.472

2.77

2.786

3.146

3.148

7.067

7.108

7.221

7.184

1-0951 1-0643

7.578

15.931

16.048

7.913

22

Min

-.

Max

-

Min

-.

-19.13 -23.894 -17.029 -17.21

-2.092 -6.854 -2.737 -2.92

-2.092 1-6.8!54 |-2.727 |-2.91

28

27

Max

10.522

10.522

2.862

2.862

Min

10.522

10.522

2.862

2.862

1

Max

11.181

11.229

3.257

3.305

Min

0.444

0.412

0.073

0.041

51

Bracing Configuration 1

Axial (+W)

Member #

COMB2a

COMB2b

COMB3a

COMB3b

COMB3c

COMB3d

COMB4a

COMB4b

COMB6a

-4.

-8.751

-8.967

-9.018

-9.009

.186

-6.667

9.039

-6.8

9.207

-3.9

-10.06

-4.033

-14.851 -9.228

-15.118 -9.27

-10.525 1-4.44

19

20

-3.2051.8

-8.827 -4.241

-8.936 -3.934

-7.113 -0.535

-7.465 0.447

-4.329 -3.121

-4.68

-2.14

-8.385 -14.911

-8.495 -14.605

1-3

-11.955

Axial Load (kips)

21

22

23

5.1

5

7.924

6.273 -0.302

8.353

6.655 -0.352

9.055

7.572 -0.642

10.425 8.797 -0.802

6.482

7.541 -7.756

7.853 8.766 -7.917

4.538

7.109 -14.252

4.966

7.A92 -14.303

1.161

4.82 -14.221

24

9.92

27.543

27.835

21.91

22.845

8.498

9.433

16.864

17.156

2.621

25

. 9

14.829

14.992

11.921

12.441

6.457

6.977

12.355

12.518

4.781

Axial (-W)

Member #

COMB3c

COMB3d

COMB4a

COMB4b

COMB6a

17

.3

-4.248

W3.226

-3.493

1.1

19

20

4081

-3.76

13219

-6.544 15.805

-6.654 116.112

-1.975 18.761

Axial Load (kips)

21

22

23

1=

13.74

10.454 5.534

16.312 10.485 12.648

116.74

10.868 12.598

12.935 7.958 12.679

24

14.49

15.414

28.826

29.118

14.583

26

.9

7.063 7.235

12.527 16.652

12.69 16.749

4.953 6.554

S

17

Earthquake

Member #

Envelope

COMB5a

COMB5b

COMB7a

COMB7b

Max

.142

.098

2.029

1.985

Member #

Enve

COMB5a

COMB5b

ICOMB7a

COMBI b

Max

0.093

.127

.084

0.119

18

18

-1.4 2

-1.605

-4.373

-4.414

0.416

17

18

Min

Max

-.

-7.456

-5.959

-3.387

-1.235

-3.343 -1.204

23

Min

-0.889

-0.854

-0.898

-0.863

Min

-6.1

-6.91

-2.186

-2.156

24

Max

Min

21.112 19.614

21.165 19.667

17.103 5.605

7.156 5.658

26

27

28

5.

0.699 10.4

18.951 1.239

31.374

19.048 1.265

31.569

14.161 1.135

23.986

24.61

14.47

1.22

4.744

1.778

10.471

5.053

1.863

11.095

12.288 3.038

23.586

23.781

12.384 3.064

2

.19 2468

7204

25

.

Axial Load (kips)

19

20

21

Max

MinM Max

M

Max

Min

71 6.2

21-6

1.

-6.52

-6.562 -1.157

-3.034 7.413 6.286

-2.04

-2081 1-976

0.099 4.336 3.209

-2.039 1-2081 2.045

0.167 4.378 3.251

2

Max

11.866

11.813

14.422

4.368

Max

15.796

15.658

15775

5.637

Min

11.659

11.521

.1.638

1.5

Max

2.854

2.73

.2.306

2.182

Min

-0.735

-0.859

-1.283

-1.407

28

11.4

12.119

25.633

25.828

9.251

22

Max

.

5.629

3.401

3408

Min

.5

5.541

3.313

3.32

28

27

26

Min

10.339

10.286

2.895

2.841

27

-0.04

0.045