No. (DAT) JUN ARCHIVES

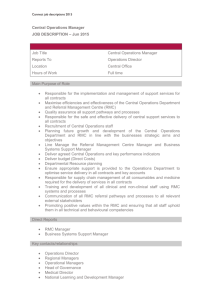

advertisement