manual: wood pole maintenance inspection and

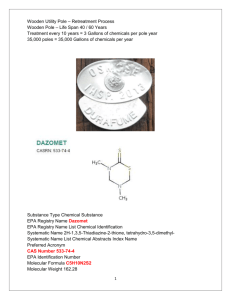

advertisement