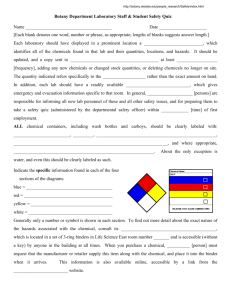

SAFE STORAGE OF LABORATORY CHEMICALS

advertisement