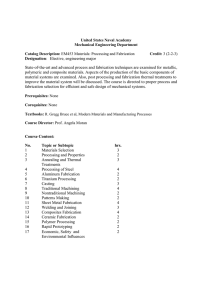

Water-based Digital Design and Fabrication:

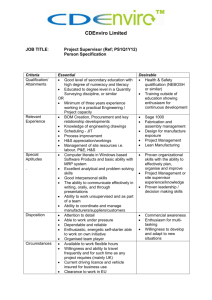

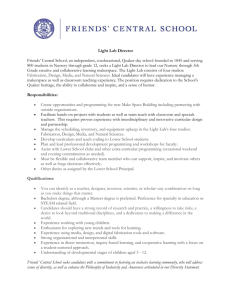

advertisement