Towards Fabrication Information Modeling (FIM): Workflow and Methods

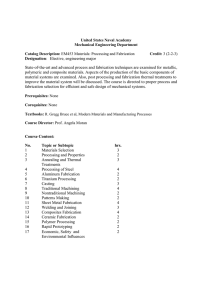

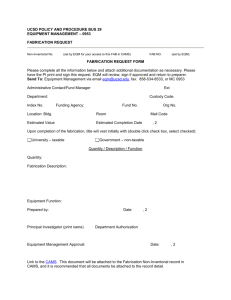

advertisement