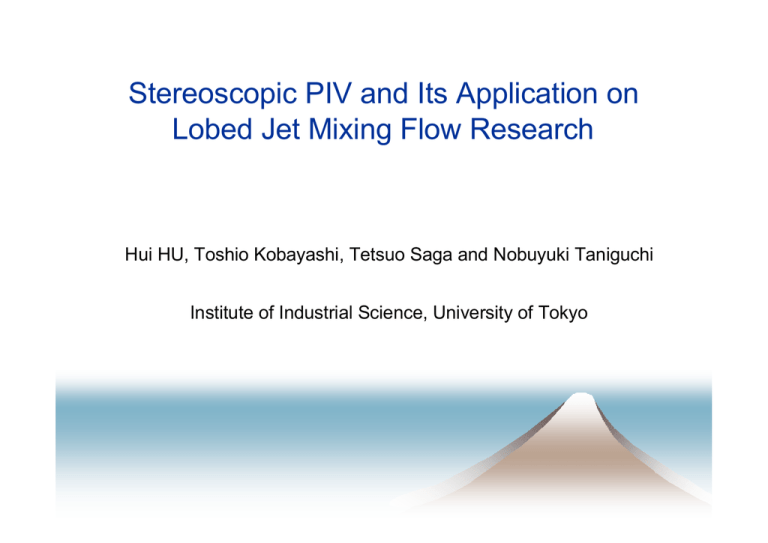

Stereoscopic PIV and Its Application on Lobed Jet Mixing Flow Research

advertisement

Stereoscopic PIV and Its Application on Lobed Jet Mixing Flow Research Hui HU, Toshio Kobayashi, Tetsuo Saga and Nobuyuki Taniguchi Institute of Industrial Science, University of Tokyo A “classical” PIV system s A typical PIV system always includes many sub-systems: • flow field seeding • flow field illumination • particle image acquisition • PIV image processing Flow field with tracer particles Illumination system (Laser and optics) Synchronizer display camera computer The shortage of “classical” PIV technique s s The "classical" PIV technique is just two dimensional method, which is only capable of recording the projection of velocity into the plane of the laser sheet, i.e the out-of-plane velocity component is lost while the in-plane components are affected by an unrecoverable error due to the perspective transformation (Nisino, 1999). For highly three-dimension flows, this can lead to substantial measurement error of the local velocity vector. In order to get the out-of plane velocity component, some three components PIV (3C-PIV) and three-dimensional PIV (3-D PIV) techniques were also be proposed. They include: • stereoscopic PIV technique • Dual-plane PIV technique • 3-D PTV technique • Holographic PIV (HPIV) Velocity three-components reconstruction by stereoscopic PIV dx11 Laser Sheet dx1 dx12 x1 α1 x3 α2 V dx3 x2 β1 x1 x3 β2 dx21 V dx1 dx22 Camera 1 Camera 2 dx3 x2 x3 Camera arrangement for stereoscopic PIV Laser Sheet Laser Sheet Camera 1 Camera 2 (a) Camera Offset Camera 1 Laser Sheet Camera 1 Camera 2 (c) Secheimpflug Camera 2 (b)Lens Offset Scheimpflug arrangement Laser sheet (object plane) Optical lens Image planes Perspective effect due to camera tilt Left camera image of grids Rectangular grid in fluid Right camera image of grids Velocity reconstruction Between exposure t and t+∆t, a particle at x moves to x+∆x, the displacement of its image: ∆X (c) = F ( x + ∆x) − F ( x) (c ) C= 1,2 for left and right camera (c) X: camera space x: flow space Performing a Taylor series expansion: ∆X 1(1) F1,1(1) (1) (1) ∆X 2 F2,1 = (2) ( 2) ∆X 1 F1,1 ∆X ( 2 ) F ( 2 ) 2 2,1 ∂F = i ∂x j (c) Where: Fi , j (c) F1, 2 (1) (1) F2, 2 (2) F1, 2 (2) F2, 2 (1) F1, 3 (1) ∆ x1 F2, 3 ( 2 ) ∆x2 F1, 3 ∆ x 3 ( 2 ) F2, 3 c = 1,2 , i = 1,2 and j = 1,2,3 Velocity reconstruction Assume the relationship function (F(x) (c)) between the fluid flow space(x1, x 2, x 3,) and camera space (X 1 (1), X 2 (1), X 1 (2) and X1 (2) ) can be expressed as an polynomial function: F ( x) = a0 + a1 x1 + a2 x2 + a3 x3 + a4 x12 + a5 x1 x2 + a6 x2 + a7 x1 x3 + a8 x2 x3 + a9 x3 2 2 + a10 x1 + a11 x1 x2 + a12 x1 x2 + a13 x2 + a14 x1 x3 3 2 2 3 2 + a15 x1 x2 x3 + a16 x2 2 x3 + a17 x1 x 2 3 + a18 x2 x32 + a19 x1 + a20 x1 x2 + a21 x1 x3 + a x x 4 3 2 2 1 3 22 1 2 + a23 x2 + a24 x1 x3 + a25 x1 x2 x3 + a26 x1 x2 x3 4 3 2 2 + a27 x2 x3 + a28 x1 x3 + a29 x1 x2 x3 + a30 x2 x3 3 2 2 2 2 2 Calibration plate for stereoscopic PIV The mapping function() ∂X ∂X ∂X ∂Y ∂Y ∂Y |L , |L , |L , |L , |L, |L ∂x ∂y ∂z ∂x ∂y ∂z ∂X ∂X ∂X ∂Y ∂Y ∂Y |R , |R , |R , |R , |R , |R ∂x ∂y ∂z ∂x ∂y ∂z 30 30 20 0 -10 -20 20 L dX/d y 0.01 6 0.01 4 0.01 2 0.01 0 0.00 8 0.00 6 0.00 4 0.00 2 0.00 0 -0.00 1 -0.00 3 -0.00 5 -0.00 7 -0.00 9 -0.01 1 10 0 -10 -20 -30 -30 -20 - 10 0 10 20 30 40 - 40 -30 -20 - 10 0 10 20 30 40 - 40 20 0 -10 -20 -30 0 -10 -20 -30 0 X mm 10 20 30 40 0 10 20 30 40 20 Ld Y/dy 15.823 15.773 15.722 15.671 15.621 15.570 15.520 15.469 15.418 15.368 15.317 15.267 15.216 15.165 15.115 10 Y mm 10 - 10 - 10 30 20 L dY/d x 0.38 2 0.33 0 0.27 9 0.22 7 0.17 5 0.12 4 0.07 2 0.02 1 -0.03 1 -0.08 3 -0.13 4 -0.18 6 -0.23 7 -0.28 9 -0.34 1 -20 -20 X mm 30 -30 -30 X mm 30 Y mm -20 -30 X mm - 40 0 -10 -30 - 40 L dX/d z -5.00 1 -5.09 8 -5.19 6 -5.29 3 -5.39 0 -5.48 8 -5.58 5 -5.68 2 -5.77 9 -5.87 7 -5.97 4 -6.07 1 -6.16 9 -6.26 6 -6.36 3 10 L dY/d z 0.67 1 0.56 2 0.45 3 0.34 5 0.23 6 0.12 8 0.01 9 -0.09 0 -0.19 8 -0.30 7 -0.41 5 -0.52 4 -0.63 3 -0.74 1 -0.85 0 10 Y mm Y mm 10 Y mm Ld X/dx 15.138 15.046 14.953 14.861 14.768 14.676 14.583 14.491 14.398 14.306 14.213 14.121 14.029 13.936 13.844 Y mm 20 30 0 -10 -20 -30 - 40 -30 -20 - 10 0 X mm 10 20 30 40 - 40 -30 -20 - 10 0 X mm 10 20 30 40 To calculate the displacement in flow space (∆x1, ∆x2 and ∆x3 ) ∆X ∆X ∆X ∆X (1) 1 (1) 2 ( 2) 1 ( 2) 2 (1) F1,1 (1) F2,1 = (2) F 1,1 F (2) 2,1 F1, 2 (1) (1) F2, 2 (2) F1, 2 (2) F2, 2 F1, 3 (1) ∆ x1 F2, 3 ( 2 ) ∆x2 F1, 3 ∆ x 3 ( 2 ) F2, 3 (1) A least squares method is used to determine the particle displacement in flow space (∆x1, ∆x2 and ∆x3 ) Lobed mixer/nozzle concept Application Aviation : jet noise suppression, improve propulsion efficiency, reduce specific fuel consumption Combustion: improve combustion efficiency, suppression pollutant formation, device size reduction The purpose of the present study 1. Research the vortical and turbulent structure changes in the jet flow 2. Analysis the mechanism of the mixing enhancement by lobed nozzles Test nozzles Circular nozzle Lobed nozzle The test lobed nozzle Y Lobe trough Lobe peak D=40mm X Z Experiment set-up for stereoscopic PIV LLS(Nd:YAG) 2D-LDV Lobed Nozzle φ 40 3D-PIV 23° 70×70 23° 544 Section 2 430 Flow Direction Section 1 Measurement results Y Y 1 0 m/s 10 m/s 0 -20 -30 Y mm 20 Z X W m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 20 0 -20 -30 -20 -20 -10 -10 0 X mm 0 10 Xm m 20 Instantaneous results 10 20 mean results In the X/D=0.5 cross section of the lobed jet flow Y mm Z X W m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 Measurement results Y Y 1 0 m/s 0 -20 -30 Y mm 20 1 0 m/s X Z W m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 20 0 -20 -30 -20 -20 -10 -10 0 Xm 0 10 m Xm 20 Instantaneous results 10 m 20 mean results In the X/D=1.0 cross section of the lobed jet flow Y mm Z X W m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 Measurement results Y Y 10 m/s Z X 1 0 m/s -20 Z 20 0 -20 -30 -20 -10 0 Xm -30 10 m -20 20 -10 0 X mm Instantaneous results 10 20 mean results In the X/D=1.0 cross section of the circular jet flow Y mm 0 Y mm 20 W m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 X W m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 Measurement results Y Y Z X Y mm 1 0 m/s U m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 20 0 -20 0 -20 -20 -10 -30 0 -20 10 m -10 20 30 0 Xm Instantaneous results U m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 20 -30 Xm X Y mm 1 0 m/s Z 10 m 20 30 mean results In the lobe peak axial slice of the lobed jet flow Measurement results Y Y 1 0 m/s 0 -20 Y mm 20 X 1 0 m/s U m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 0 -20 -20 -30 0 Xm -20 10 m -10 20 0 30 Xm Instantaneous results X U m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 20 -30 -10 Z Y mm Z 10 m 20 30 mean results In the lobe trough axial slice of the lobed jet flow Measurement results Y Y U m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 20 0 -20 1 0 m/s 0 -20 -30 -20 -10 -10 0 Xm 0 10 m 20 Xm 30 X U m/s 13.00 12.00 11.00 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 20 -30 -20 Z Y mm X Y mm 1 0 m/s Z 10 m 20 Instantaneous results In the axial slice of the circular jet flow 30 mean results The comparison of Stereoscopic PIV and LDV measurement results 12 piv-v piv-w ldv-w ldv-v Velocity m/s 10 8 6 4 2 0 -2 0 10 20 30 40 50 60 70 80 90 100 time (*15) s Stereoscopic PIV X direction Y direction Z direction In plane Out plane X direction LDV Y direction u Std(u) v Std(v) w Std(w) u Std(u) v Std(v) 22.75 1.12 0.79 0.94 -0.13 1.48 21.80 1.71 1.34 1.96 22.06 7.86 3.17 1.32 0.51 0.74 0.53 0.21 0.26 1.01 0.22 0.36 -0.33 -0.23 -0.42 0.73 0.24 0.45 21.85 7.42 3.37 2.92 0.70 0.77 1.49 0.41 0.58 2.82 0.37 0.86 Z direction w Std(w)