Linearly-Acting Variable-Reluctance Generator for Thermoacoustic Applications

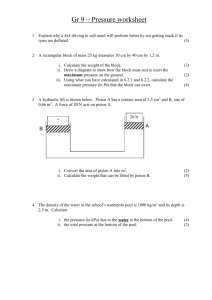

advertisement