Preparation of Silica Aerogels with Improved Mechanical

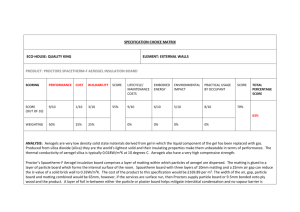

advertisement