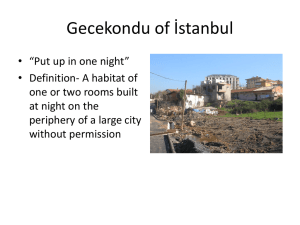

Semi-Nonstandard Construction and Its Application in Post-Squatter İstanbul

advertisement