Methodology for Capturing and Measuring Dissolved

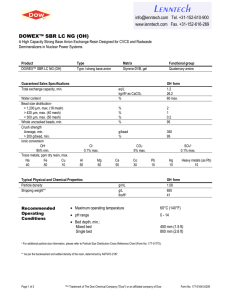

advertisement