Functional Thin Film Polymers for Biopassivation of Neuroprosthetic ... W. Shannan O'Shaughnessy by

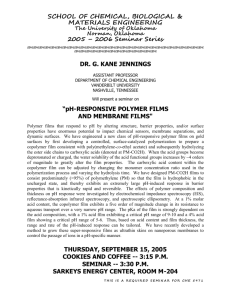

advertisement