Using the FLUENT Computational Fluid Dynamics Code

advertisement

Using the FLUENT Computational Fluid Dynamics Code

to Model the NACOK Corrosion Test

By

Benjamin T. Parks

B.S. With High Distinction (2003)

Mechanical Engineering with Concentration in Nuclear

Worcester Polytechnic Institute

Submitted to the Department of Nuclear Engineering

In partial fulfillment of the requirements for the degree of

Master of Science in Nuclear Engineering

At the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

August, 2004

MASSACHUSETTS INsT

OF TECHNOLOGY

C 2004 Massachusetts Institute of Technology

All Rights Reserved.

DEC 27 2006

LIBRARIES

Author

__._

'"

--

w ............

I"

"

"U""

"

"

"

"

Department of Nuclear Engineering

Certified by

Professor Andrew C. Kadak

Thesis Advisor

""~"I'"IUIII""""~~"'""I········I········

Certified by

Professor Sidney Yip

Thesis Advisor

Certified by

Lin-Wen Hu

Thesis Reader

..'T'~·2·""~"~Zf=pr"r~uulC-"··

.....

.....

..

~··'"~"'

·--

--

--~~~·I"·"···~···'·~~'·~~'

"`·"--

· L

~~'·"·"'~""~~·I^·'~···~"-·'~··"^-··"~~·

Accepted by .~

.

Professor Jeffrey A. Coderre

Chairman, Department Committee on Graduate Students

ARCHIVES

Using the FLUENT Computational Fluid Dynamics Code

to Model the NACOK Corrosion Test

by

Benjamin T. Parks

Submitted to the Department of Nuclear Engineering

On 19 August, 2004 in Partial Fulfillment of the

Requirements for the Degree of Master of.Science in

Nuclear Engineering

Abstract

As a part of advancing nuclear technology, computational fluid dynamics (CFD) analysis

offers safer and lower-cost results relative to experimental work. Its use as a safety analysis tool is

gaining much broader acceptance due to increasing experimental verification. FLUENT is a

Computational Fluid Dynamics (CFD) code that offers extensive benchmarks and validations, and is

widely accepted by the nuclear engineering community. The Modular Pebble Bed Reactor (MPBR) is

among the advanced reactor designs proposed for future deployment. As such, it offers an excellent

opportunity to illustrate the possible contributions of computational modeling to the reactor design

process. Because the MPBR contains graphite structures and fuel elements, there is significant

concern about graphite heating and chemical reactions during an air ingress accident.

Some MPBR-relevant experimental safety assurances have been benchmarked using

FLUENT. Currently, there is a planned experiment involving natural convection flow and graphite

corrosion at the Forschungzentrum Julich in Julich, Germany. Thus far, only a preliminary test of

this experiment has been performed. This test has been called the NACOK Corrosion Test, and this

thesis presents a model of the test configuration. A methodology is developed by which an efficient

analysis of the flow, heat transfer, and corrosion effects of the test are modeled using the FLUENT

software. An adequate grid resolution is determined that allows computationally efficient analysis.

Steady-state and transient flow and heat transfer effects are modeled, and separate models contain

steady-state and transient chemistry effects.

The steady-state flow and heat transfer model was used for the grid refinement study; it was

determined that a fully-structured, 4,508 element grid was sufficient for analysis of this experiment.

The transient flow and heat transfer model confirmed the results of the steady-state analysis in that

the transient model had results similar to those of the steady-state model. An effort was made to

couple a density-driven pressure drop correlation to this model; however, because of the requirement

of a general pressure-drop specification for the entire model, and the temperature dependence of the

correlation, an over-specification resulted that caused the solution to diverge. Because the ambient

air that causes the buoyancy-induced pressure drop is not modeled, it was determined that specifying

a general pressure drop for the entire model was a sufficient and relevant assumption.

The steady-state chemistry model was used to perform sensitivity studies by varying the flow

rate, graphite temperature, and stoicheometry. Increasing the flow rate results in quicker graphite

consumption, although the oxygen exits the system less depleted. Increasing the graphite

temperature seems to have little effect on the chemistry effects of the model. Varying the

stoicheometry indicated that more heat is released by CO 2 production. Overall, it was determined

that most of the graphite chemistry occurs in the reflector region of the model. A transient

chemistry model was also created, but because mass transport effects were not modeled, the solution

tended to steady-state operation, rather than eventual graphite cooling, which would be the expected

result of this test in the laboratory setting.

Thesis Supervisor: Andrew C. Kadak

Title: Professor of the Practice of Nuclear Engineering

-3-

Table of Contents

ABSTRACT ..................................................................................................................................................

3

ACKNOWLEDGMENTS ...........

8

1

2

3

INTRODUCTION ..............................

6

7

..........................................................................................

9

1.1

BACKGROUND INFORMATION ........................................................................................................

1.2

MPBR-RELEVANT EXPERIMENTAL SAFETY ASSURANCES ........................................ 17

1.3

FLUENT CFD ..................................................

NACOK DESCRIPTION .........................................

9

19

..............................................................

21

2.1

THE NACOK FLOW TEST............................................................................................................22

2.2

THE NACOK CORROSION TEST .................................................................................................. 24

THESIS GOAL AND OBJECTIVES ........................................................................................

29

3.1

THESIS GOAL ............................................................................................................................... 29

3.2

THESIS OBJECTIVES AND TASK DESCRIPTIONS ..........................................

4

5

........ ......................

............... 29

FLUENT METHODOLOGY ........................................................................................................... 31

4.1

DEVELOP MODELS INGAMBIT ..................................................................................................... 31

4.2

APPLY BOUNDARY CONDITIONS USING THE FLUENT PROCESSOR ....................................

4.3

RUN THE FLUENT CODE ............................................................................................................ 31

4.4

EXAMINE RESULTS ..................................................

. 31

31

STEADY-STATE FLOW MODEL .................................................................................................

33

5.1

GRID CREATION ...........................................................................................................................

33

5.2

REGENERATOR ANALYSIS....................................................

36

5.3

SOLVER SPECIFICATIONS FOR THE STEADY-STATE CASE....................................

5.4

BOUNDARY CONDITIONS SUPPLIED TO THE STEADY-STATE CASE .....................................

5.5

RESULTS OF STEADY-STATE ANALYSIS .........................................................

5.6

CONCLUSIONS OF THE STEADY-STATE ANALYSIS .........................................

........... 42

. 43

...................... 45

.............. 50

MODELING A BUOYANCY-DRIVEN FLOW .........................................................................

53

6.1

COUPLING THE ZHAI DENSITY FUNCTION TO THE NACOK CORROSION MODEL..................... 53

6.2

OBTAINING THE APPROPRIATE FLOW ASSUMPTIONS ........................................

...........

58

TRANSIENT FLOW MODEL ......................................................................................................... 63

7.1

TRANSIENT SOLUTION MODEL SETUP AND EXECUTION .............................................................. 63

-4-

.....................

65

7.2

RESULTS FROM THE TRANSIENT ANALYSIS .....................................

7.3

CONCLUSIONS..............................................................................................................................

67

CARBON-CHEMISTRY MODEL AND SENSITIVITY STUDY ......................................

69

8

8.1

CHEMISTRY MODEL SETUP..........................................................................................................

69

8.2

RESULTS OF THE BASE-CASE, STEADY STATE CHEMISTRY MODEL....................................

71

8.3

RESULTS OF THE SENSITIVITY STUDIES ..............................................................

75

8.4

RESULTS OF THE TRANSIENT MODEL...................................................................................

81

8.5

C ONCLUSIONS ..............................................................................................................................

82

9

CONCLUSIONS ................................................................................................................................

85

9.1

M ESH REFINEMENT .....................................................................................................................

9.2

THE ZHAI AND KUHLMANN PRESSURE DROP CORRELATIONS ................................................... 86

9.3

LACK OF MASS TRANSPORT MODELING .........................................

86

9.4

SENSITIVITY A NALYSIS ...............................................................................................................

87

9.5

RECOMMENDATIONS FOR FURTHER ANALYSIS ........................................................................

88

REFERENCES ...........................................................................................................................................

-5-

85

89

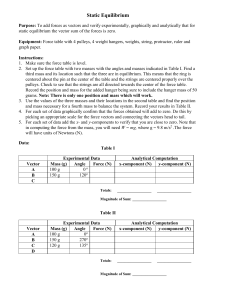

List of Figures and Tables

Figure 1.1. MPBR Schematic Showing Graphite Central Column in Offset Shading .......................... 12

Figure 1.2. Schematic of the Reflector Region of the MPBR ........................................

...... 13

Figure 1.3. MPBR Fuel Pebbles and TRISO Particles ...................................................

15

Figure 1.4. Schematic of JAERI Experiments.......................................................................................18

Figure 2.1. NACOK Experimental Device Schematic. ..................................................

22

Figure 2.2. NACOK Corrosion Vessel Schematic................................................................................25

Figure 2.3. Results of the Preliminary NACOK Corrosion Test .......................................

Figure 5.1. Schematic of Grid Created for NACOK Model...................................

..... 27

........ 34

Figure 5.2. Successive refinements imposed on NACOK grid structure ................................................ 35

Figure 5.3. Regenerator Effectiveness Plot. ............................................................................................ 41

Figure 5.4. Contours of Static Pressure. ...................................................... ............................................ 46

Figure 5.5. Contours of Temperature. ........................................................ ............................................. 47

Figure 5.6. Contours of Y-Velocity. .......................................................... ............................................... 48

Figure 6.1. Comparion of Zhai and Kuhlmann Pressure Drop Correlations. ...................................

57

................

60

Figure 7.1. Time Step Size Versus Iteration Number. ...................................................

65

Figure 7.3. Comparison of Transient Temperature to Steady-State Temperature ...................

67

Figure 8.1. Comparison of Species Mass Fractions .....................................................

72

Figure 6.2. Mass Flow as a Function of Pressure Drop................................

Figure 8.2. Contours of Oxygen Concentration....................................................................................73

Figure 8.3. Contours of Static Temperature. .......................................................................................... 75

-6-

Figure 8.4. Exit Gas Concentrations as a Function of Pressure Drop...........................

...... 76

Figure 8.5. Exit Component Mass Flows as a Function of Pressure Drop. ..................................... 77

.... 78

Figure 8.6. Exit Gas Concentrations as a Function of Temeprature. ....................................

Figure 8.7. Species Mass Fractions as a Function of CO Stoicheometry.............................

..... 80

Figure 8.8. Reflector and Pebble-Bed Temperatures as a Function of Stoicheometry. .....................

Figure 8.9. Species Concentrations as a Function of Time .........................................

81

....... 82

Table 5.1. Velocities in Upper Void Region of Grid. .......................................................................... 49

Table 5.2. Results of the Steady-State M odel...............................................

........................................ 50

Table 6.1. Comparison of Zhai Correlation to Kuhlmann Correlation at Various Temperatures......56

Table 6.2. Comparison of Pressure Change for a Non-Isothermal Pebble Bed....................................

58

Table 6.3. Pressure Drop Comparison of NACOK Column and Ambient Air Column. ................. 59

Table 8.1. Tabulated Results of Pressure Drop Sensitivity Study. .....................................

.... 78

Table 8.2. Tabulated Results of Temperature Sensitivity Study. ............................................................

-7-

79

Acknowledgments

This work was financially supported by the United States Nuclear Regulatory Commission.

The academic support provided by Thesis Supervisor Professor Andrew C. Kadak, and by Thesis

Co-Supervisor Professor Sydney Yip, is gratefully acknowledged.

The academic support and technical assistance provided by Thesis Reader Lin-Wen Hu is also very

gratefully recognized.

This work is performed as a follow-up to the Nuclear Engineer's Thesis of Tieliang Zhai. For his

preliminary work, and for his consultations, he is sincerely acknowledged.

The relentless moral support provided by Daniel Cavallari, Lisa Mullen, Whitney Raas, and Peter

Yarsky is also very gratefully and lovingly acknowledged.

-8-

1

Introduction

There has been great recent interest in the use of computational fluid dynamics (CFD) codes for

regulatory analysis of nuclear reactors, because a computational analysis of an important, previously

untested safety feature offers several benefits. First, a computational analysis can reveal unforeseen

safety hazards that would pose a threat to technicians in an experimental environment. Second,

given the validity of an advanced code, analysis can eliminate the need for some experimental work,

thereby reducing the cost of research and development.

With these two goals in mind, the goal of this thesis research was to develop a computational model

of a planned experiment that would demonstrate the safety of the Modular Pebble Bed Reactor

(MPBR) under air ingress accident conditions. The section that follows provides the context under

which the research was performed. It includes background information about the research initiative

that inspired the development of the MPBR, a brief overview of the reactor and the air ingress

accident and significant carbon chemistry, and a description of Fluent CFD, the code chosen to run

the model. This chapter also contains the thesis goals and objectives.

1.1

Background Information

In anticipation of growing energy demands on a world-wide level, the United States Department of

Energy has begun an effort to inspire international participation to develop a new generation of

nuclear reactors [1]. The goals for the development of these reactors are (as quoted from the

Generation IV Technology Roadmap [2]):

*

Provide sustainable energy generation that meets clean air objectives and promotes longterm availability of systems and effective fuel utilization for worldwide energy production.

*

Minimize and manage their nuclear waste and notably reduce the long term stewardship

burden in the future, thereby improving protection for the public health and the

environment.

*

Increase the assurance that they are a very unattractive and least desirable route for diversion

or theft of weapons-usable materials.

*

Excel in safety and reliability.

*

Have a very low likelihood and degree of reactor core damage.

-9-

*

Eliminate the need for offsite emergency response.

*

Have a clear life-cycle cost advantage over other energy sources.

*

Have a level of financial risk comparable to other energy projects.

By setting forth these goals in its Gen-IV Initiative, the DOE hopes to make research and

development of new nuclear reactors more attractive to universities and private industry. Note that

the DOE does not aim to design and build these reactors itself; it aims only at researching that which

is long-term and carries with it a high financial risk.

Much of the DOE's research effort is

concentrated on regulatory work- accident modeling and the like.

One type of technology that is candidate to the Gen-IV family of reactors is the Modular Pebble Bed

Reactor (MPBR) [2].

It features spherical fuel elements, which are cooled by helium at high

0

temperatures (500 C-10000 C). The power output ranges from approximately 250 to 400 MWth for

safety and ease of deployment.

1.1.1

MPBR Description

The concept of using spherical fuel elements in a reactor, cooled by helium, stems from a larger

category of nuclear reactors, the high-temperature gas reactor (HTGR) [3]. The HTGR concept was

developed in the 1960's. American efforts at the HTGR included a small, mobile reactor concept for

military applications, called the Mobile-Low Power 1, that was abandoned [3] because it never

produced a net power output. Commercially, an HTGR at Fort St. Vrain was constructed in the

1970's, but the plant had mechanical problems and was shut down in 1989.

Finally, American

experience with the reactor Peach Bottom 1 demonstrated successful use of a gas reactor, with high

efficiency rates, low occupational dose rates, and valuable improvements to coated particle fuel

technology.

Germany has developed several reactors based on the pebble-bed concept, including the 40 MWth

AVR, which operated for 22 years, and the 300 MWe Thorium High Temperature Reactor (THTR),

which operated from June 1987 to October 1989 [3]. The fact that the Germans have operational

experience using pebble-bed reactors makes this type of reactor attractive because it is not entirely a

new technology [4].

-10-

1.1.1.1

The MPBR Core Design [5]

The reactor core sits inside a pressure vessel, surrounded by a graphite reflector. Approximately

300,000 fuel pebbles, each 6 cm in diameter, fill the core. Graphite control rods are inserted from the

top of the pressure vessel around the pebble column to moderate the fission reaction. The core and

pressure vessel are cylindrical, the core being approximately 3.5 m in diameter and the pressure vessel

being around 6m in diameter, which allows for graphite reflector blocks surrounding the core. The

height of the reactor core is 10m. Figure 1.1 shows a schematic diagram of the reactor.

- 11 -

Figure 1.1. MPBR Schematic Showing Graphite Central Column in Offset Shading.

Each pebble is assumed to operate at approximately 10000 C, and the rated power output is 120 MWe

or 265 MWth. Helium is used to cool the reactor. It enters the core at roughly 522 0C and 8MPa.

The helium exits at around 9000 C at full power. The power density is less than 4.8MWth/m

-12-

3

[6].

A significant feature of the MPBR that is very relevant to this thesis is the bottom reflector structure.

It is expected that a majority of the chemical interactions discussed in §1.1.3 occur in the reflector.

Figure 1.2 depicts a cross section of the reflector region of the MPBR that was created in GAMBIT.

Figure 1.2. Schematic of the Reflector Region of the MPBR [19].

In Figure 1.2, the reflector is the structure in the center. It has cylindrical-shaped flow channels in it,

and has an inverse conical shape that holds the pebble bed.

Eventually, the nuclear reaction consumes the supply of fissile matter in the fuel pebble. In order to

ensure high power availability, the pebble bed reactor is designed for online refueling.

This

recirculation of pebbles allows the plant operator to monitor the burnup of the pebbles while the

reactor is operating. Every thirty seconds, a fuel pebble is removed from the bottom of the core and

checked for its burnup. If the fuel is nearing expected burnup, the pebble is disposed. If not, the

pebble is placed back in the reactor. It is expected that pebbles can circulate through the reactor up

to ten times before requiring disposal and replacement.

In order to attain a uniform cross-core neutron flux level, a column of graphite pebbles can be found

in the center of the core. The column, illustrated in Figure 1.1, serves as a reflector, which allows for

uniform power distribution and provides adequate control using the control rods in the reflector.

-13-

The Pebble Bed Modular Reactor (PBMR) being designed in South Africa replaces this central

column of pebbles with a fixed, solid column of graphite.

1.1.1.2

Safety Aspects

A large part of the pebble-bed reactor design stems from the safety goals of the Gen IV Initiative.

Below are some of the resultant safety aspects that are a key part of the reactor design.

Helium is chosen as the coolant because it is "chemically and radiologically inert" [7]. This means

that the helium coolant will not react with its cooling system. This is a problem in water-cooled

reactors because radiolysis causes oxygen production in the cooling system, which leads to corrosion

of the fuel cladding and the reactor core cooling system. The use of a radiologically inert coolant

enables the coolant's use for power conversion in a direct cycle, without the risk of sending

radioactive coolant through unnecessary systems. Further, no risk of helium phase-change during

operation or transient is possible, which is an additional safety feature.

The issue of containment in a nuclear power plant is a large one when considering the potential for

release of radioactive material to the atmosphere. Essentially, the fission products in a nuclear power

reactor must be contained at all circumstances.

Traditionally, containment is provided by a large, pre-stressed concrete structure designed to

withstand large-scale plant accidents. The containment serves also as a fission product barrier. In a

pebble bed reactor, however, the primary fission product boundary is provided by the silicon carbide

coated particle fuel. Although the MPBR has steel and concrete confinement structures, the fuel

pebble is designed to contain fission products during accidents and transients. The fuel pebble is a

spherical graphite shell that contains approximately 15,000 fuel kernels. Each fuel kernel is a TRISOcoated microsphere of 8% enriched UO 2 or UCO. Figure 1.3 illustrates the TRISO coating and fuel

pebble composition.

-14-

5mm Graphite layer

Coated particles imbedded

inGraphite Matrix

Dia. 50mm

Fuel Sphere

ryrolyc Laraon

~

Silicon Carbile Barrier Costing

Inner Pyrolic Carbon

Porous Carbon Buffer

Half Section

Dia. 0,92mm

Coated Particle

Dia.O,Smm

Uranium Dioxide

Fuel

Figure 1.3. MPBR Fuel Pebbles and TRISO Particles.

1.1.2

MPBR LOCA and the Air Ingress Accident

The air-ingress accident scenario is of particular interest to the MPBR designers. Because the reactor

relies on a large volume of graphite as part of the core design, air ingress is an accident with

potentially severe consequences. If air is permitted to flow freely through the reactor core at high

temperatures, graphite fires could result. Thus, "limiting the possibilities of chemical degradation of

the fuel due to large scale air or water ingress" has been identified as a major design goal of the

pebble-bed reactor [6]. The following text helps to describe the expected behavior of a graphite

reactor during loss-of-coolant and air ingress accident.

The first part of a LOCA accident in a gas-cooled reactor is the depressurization, where the helium

blows out of the reactor core until effectively atmospheric conditions are reached [8]. During this

stage, there is nearly no possibility of air ingress into the MPBR core, since the helium remains at a

greater pressure inside the core than that of the air outside the core.

The second part of the LOCA occurs when the helium remains inside the core at ambient pressure.

During this stage, the fuel temperature rises due to the loss of forced convection.

The fuel

temperature peaks as the reactivity and reactor power decrease. This negative coefficient of reactivity

is an inherent safety feature of the pebble bed reactor design.

-15-

Despite the fact that there is a break at the coaxial coolant pipe, which is located near the bottom of

the reactor, the helium gas is lighter than the air that is at the break, and buoyancy forces therefore

prevent large amounts of air from entering the reactor core. Small amounts of air, however, are

capable of entering the core via molecular diffusion, which is a very slow process. As this process

occurs, the air begins to oxidize the graphite in the reactor, and a small amount of localized heating

begins as a result of the oxidation reactions. As a result of the reactions and the decay heat present

in the core, a natural convection flow begins to establish, which draws more air into the core.

1.1.3

Carbon Chemistry Relevant to the Air Ingress Accident

As a result of a LOCA and the air ingress, the following chemical interactions are anticipated. Prior

to the full onset of natural convection, core heating can be expected [9]. The graphite structural

material may be damaged due to heating and oxidation, which could result in a loss of mechanical

stability of the core, although this mechanical instability is anticipated at about 40 hours after an

accident that would cause multiple breaks at various locations throughout the core. It follows that

the graphite fuel coating could also be damaged, due to the same phenomena, which exposes the

silicon carbide fuel coating and therefore could result in higher probability of fuel coating failure. It

is also likely that the core heating could endanger metallic components near the core.

Finally,

combustible gas mixtures could be created according to the series of oxidation reactions described

below [10,11,12].

+1 02 -+ CO

2

C+0

2

-+ CO 2

C+CO 2 - 2CO

2CO+0

2

-+ 2CO 2

A = -11lllkJmol

(1-1)

A = -394kJ mol

(1-2)

= 172kJ/mol

(1-3)

AH = 566kJ/mol

(1-4)

In graphite channels, these reactions begin to activate at approximately 600C [13].

In a lower temperature range, which extends from 600"C to approximately 700'C, the formation of

CO 2 by graphite oxidation is the dominant reaction [10]. In this temperature range, the consumption

of carbon is fairly uniform throughout the entire region of graphite; the reaction rate at this

temperature is sufficiently low to allow thorough diffusion of oxygen throughout the graphite

-16-

surfaces. Therefore, carbon transport occurs through the depth of the carbon, rather than just at the

surface.

However, at temperatures above 700'C, the formation of CO and the corresponding CO

combustion reaction begin to generate heat. At this point, the carbon chemistry occurs at a higher

rate, and therefore, there isn't sufficient time for the oxygen to diffuse through the carbon before it is

consumed. Accordingly, the chemical interactions in this higher temperature occur mainly on the

carbon surface, rather than at depths through the carbon.

This is called the "boundary layer

controlled [temperature] regime." [10] With increasing temperature through this range, CO becomes

the dominant product of graphite oxidation.

Of concern is the amount of CO produced in the reactor, since the reaction described by Eguation

1-4 results in burning with a visible flame [13]. It should be noted that the combustion reactions will

only occur if sufficient air is provided (i.e., the oxygen is not properly consumed) and if the incident

air and graphite both maintain a sufficiently high temperature (in the range of 700"C to 1000 0C).

Given this description of carbon chemistry, one can expect that the majority of the carbon oxidation

will occur on the surface of the reflector structures located at the bottom of the reactor.

1.2

MPBR-Relevant Experimental Safety Assurances

Given the potential severity of the air-ingress accident that could face the MPBR, it is in the

designer's best interests to explore the associated phenomena carefully through experimental work,

which assures a more controllable environment than a full-scale nuclear reactor. Scientists in Japan

and Germany have performed such experiments, and German scientists have planned further

experimentation.

In Japan, scientists at the Japan Atomic Energy Research Institute (JAERI) have performed a series

of experiments in an upside-down, u-shaped tube that extends from the top of a large drum

[12,14,15]. The device is illustrated schematically in Figure 1.4. In the first such experiment, the

molecular diffusion of nitrogen in the drum into helium in the tube was investigated in an isothermal

environment. In the second experiment, the same, two-component gas mixture was used, but the

helium tube was heated on one side and cooled on the other to establish a hot and cold leg, which

would allow the establishment of a natural convection loop. In the third experiment, oxygen was

added to the nitrogen in the drum region to simulate actual air, and a graphite pipe was inserted into

a part of the heated tube region. In this experiment, molecular diffusion, natural convection, and

corrosion were studied.

These experiments provided a comprehensive investigation of three

phenomena that are very significant to the MPBR air ingress accident:

-17-

*

Molecular diffusion, significant in the first part of the accident,

*

Natural convection, significant in later stages of the accident, and

*

Graphite corrosion, significant as air reaches the carbon components of the core.

I11_11

1

ure

Point

ture

Point

Figure 1.4. Schematic of JAERI Experiments [8]

-18-

It is noteworthy that the series of JAERI experiments were performed to investigate the safety of a

prismatic reactor; therefore, investigating the corrosion and flow behavior in a graphite channel was

sufficient. This work was simulated using the FLUENT Computational Fluid Dynamics Code in the

thesis work of Tieliang Zhai [19]. However, as an investigation of the phenomena in a pebble-bed

reactor, the experiments were slightly incomplete.

To complete the portfolio of experimental safety assurances, scientists at the Forschungzentrum

Julich in Julich, Germany completed a series of natural convection flow tests in a heated vertical

channel containing a pebble-bed.

The scientists plan to investigate the corrosion behavior of

graphite pebbles in the vertical channel.

These tests, which are called NACOK, the German

translation of Natural Convection in the Core with Corrosion, are discussed in further detail in

Chapter 2.

1.3

Fluent CFD

Fluent has been chosen as the modeling software [16]. It is a popular computational tool used to

model complex thermal-hydraulic phenomena. Because of extensive benchmarking, it is frequently

accepted as an excellent predictor of fluid flow behavior. FLUENT is capable of computationally

modeling fluid flow, heat transport, and chemical reactions and species mixing in two and three

dimensions. It is capable of both time-dependent (transient) and steady-state computations.

-19-

This page intentionally left blank.

- 20 -

2

NACOK Description

As discussed in §1.3, several apparatus have been designed to investigate the behavior of the reactor

under air-ingress accident conditions. These experiments have been constructed with components

that pose no threat of nuclear reaction or radioactive release. The first series of experiments were

performed at the Japan Atomic Energy Research Institute (JAERI).

The second series of

experiments were performed at Forschungszentrum Jiilich, a German research institute [17]. The

German NACOK Experiments are discussed in this chapter in further detail.

NACOK stands for the German translation of 'Natural Convection in the Core with Corrosion'.

This device more closely simulates the pebble-bed environment of the MPBR than that of the JAERI

devices discussed in the preceding section.

As illustrated in Figure 2.1, it consists of an

experimentation channel, into which graphite pebbles may be inserted, heaters, and a flow of He, N 2

and simulated air.

Two types of experiments were performed with this device. A natural circulation experiment was

performed using the device illustrated in Figure 2.2.

Also, a corrosion test was performed as a

precursor to a more detailed experiment. The corrosion test made use only of the experimentation

channel; the incident gas flowed out of the top of the device.

- 21 -

experir

300mrr

sphere

dsphere:

1

r

flow din

heater

0)

0

UJ,

steel fn

\

I

_~ _ I_

NACOK

Figure 2.1. NACOK Experimental Device Schematic [18].

2.1

The NACOK Flow Test

In the flow experiment, full-sized ceramic pebbles, 60mm in diameter, were inserted in the

experimentation channel to develop an understanding of the flow around pebbles of actual size. The

experimentation channel and recirculating pipe were heated to different temperature combinations so

that the experimentation channel would serve as a hot leg and the recirculating pipe would serve as a

cold leg; thus a natural convection loop could be established.

- 22 -

As a result of the heating and cooling present in the experiment, and the temperature-dependent

nature of the density of air (air density decreases as temperature increases), the air in the pebble bed

begins to heat, and, as a result of its density decrease, becomes buoyant and rises through the heated

channel. On the cold leg, the air is cooled. As its density increases, it falls through the cold leg, and

exits through the outlet of the device.

The mass flow was measured, and pressure drop correlations were developed for the pebble-bed

flow, based on the forty different temperature combinations. Ultimately, Kuhlmann developed a

correlation that takes the form

a

b

C =Re

Re

0.(

where

=

Pressure Drop Factor in Pa/m or N/m3 ,

Re

=

Reynolds number based on characteristic length and velocity of the pebble bed,

S

=

Pebble bed porosity, 0.395, and

a, b

=

Experimentally determined coefficients.

Prior to the NACOK experiments, the German Nuclear Technology Committee (KTA) had

expressed a and b as 320 and 6, respectively. This correlation is for laminar flow for superficial

Reynolds numbers up to 10,000. With the NACOK device, a and b values of 505 and 0.1 were

found to be more relevant for 10<Re<120.

Since the Reynolds number incorporates the density of the incident fluid, these correlations become

significant for the pressure drop that arises from a density-driven flow, such as the one investigated

in this experiment, as well as the one investigated in the corrosion experiment described in §2.2.

Zhai incorporated this density formulation in his model of this NACOK flow test [19].

This flow test involved ceramic pebbles. Therefore, corrosion behavior was not explored in this

particular configuration. To investigate the corrosion behavior, the experiment is reconfigured. The

reconfiguration is discussed in the next section.

- 23 -

2.2

The NACOK Corrosion Test

A different, open device was also designed for insertion into the top of the flow channel of the

NACOK device. This device contained a graphite reflector and half-diameter graphite pebbles. This

device, which is used to investigate the corrosion of graphite pebbles and reflector blocks, was the

focus of the research discussed in this thesis. It should be noted that only a preliminary test of this

experiment has been performed, and that limited data (discussed later in this section and shown in

Figure 2.3) are available from that test.

The existing NACOK corrosion experiment is illustrated in Figure 2.2. This experimental device

consists of a graphite reflector, a small amount of 30mm diameter graphite pebbles (enough for 5

layers of pebbles), and a load lattice that sits on top of the small pebbles to simulate the weight of the

upper region of the pebble bed. These devices are all located in a plenum that fits inside the

experimentation channel of the NACOK device illustrated in Figure 2.1. While resting inside the

experimental channel, a 5-m deep column of 60mm-diameter, ceramic pebbles remains below the

corrosion vessel.

- 24-

Figure 2.2. NACOK Corrosion Vessel Schematic [17].

The reflector comprises the lower zone of the corrosion vessel. The experimental reflector is a

graphite cube that has an edge length of 198mm. It has a staggered array of cylindrical flow channels

in it; there is a stainless steel support plate below it with the same pattern of drillings such that the

flow channels align.

The next zone is the region with the pebbles. In the experiment, graphite pebbles, each 30mm in

diameter, are placed in five layers above the reflector. The graphite used for the pebbles is of type

A3-3, whereas the reflector graphite is ASR-1RS.

Kuhlman suggests that the corrosion behaviors

and structural properties of these two types of graphite are very similar [17]. Because it is expected

that the reaction with the reflector will consume most of the oxygen, only five layers of pebbles are

- 25 -

included in the apparatus.

A preliminary investigation of this experiment showed complete

consumption of oxygen, which indicates that the oxidation rate will be maximized in the experiment.

The final zone is the load lattice. The load lattice is a grid structure of stainless steel that sits above

the five layers of pebbles. This lattice is used to simulate the weight of the remaining portion of the

pebble bed, so that, if there are structural changes in the lower five layers of pebbles, the changes will

occur as they would if an entire column of pebbles were above them.

Using the device described above, scientists at the Forschungzentrum Julich ran a preliminary test of

this corrosion experiment.

Due to the preliminary nature of the test, the available data are very

limited; they consist of the plot shown in Figure 2.3, which includes an oxygen concentration curve,

and several temperatures plots, all as functions of time.

To run the corrosion experiment, nitrogen at 650'C is blown into the experimental apparatus for a

sufficiently long time to ensure that all components are at a thermal equilibrium of 650 0 C. Once this

occurs, the entrance of the device is left open to air, with an established natural convection updraft.

As the air with 21% oxygen by volume enters, the oxygen present corrodes the graphite in the

corrosion vessel, leaving CO 2 and CO as products of the corrosion reactions.

These chemical

reactions are mostly exothermic, and therefore heat is released. This release causes the temperature

of the device to increase locally, establishing a natural convection flow.

- 26 -

_

1150s

__

·_

IU

_·_

crQp

ane atslo(~d %)

I

I

A

I

I

S

I

I

1050.

Wo

-- -- --

-I--------

i\

Mid A-o

---

Upa ME

'

.......

]• - -'-

"•, -.,,•

.4

rjcrl6

I

--

a,

-

0:rm

e.00

11Tim

(mn)

Figure 2.3. Results of the Preliminary NACOK Corrosion Test.

In Figure 2.3, Line 1 corresponds to the temperature at the bottom of the reflector, Line 2

corresponds to the middle of the reflector, and Line 3 corresponds to the top of the reflector. Gases

were measured at the axial center of the reflector. Line 4 corresponds to the temperature at the

bottom of the pebble bed. The oxygen curve is depicted on the left; it is scaled on the right axis.

The time is given minutes. The oxygen was measured at the exit of the corrosion vessel.

In Figure 2.3, we see that Line 4 shows an initial increase in temperature, which is followed by a

decrease. The initial heating trend at this location, which is the bottom of the upper, graphite pebble

bed, is due to the initial reaction kinetics.

Although the reaction accelerates first in the lower

portions of the reflector region, small amounts of energy are added to the incident air as it flows

through the graphite channels. This energy transfer results in an initial heating of the upper regions

of the graphite, where the oxygen has been entirely consumed. The result is that the air begins to

elevate slightly in temperature, which in turn heats the graphite in the pebble bed. As the graphite in

the pebble bed heats, the local reaction rates in the pebble bed begin to accelerate, such that the

reaction is occurring more quickly in the pebble bed, above the reflector. The carbon reactions

release more energy, which causes the graphite in the pebble bed to heat further. This heat conducts

through the graphite, against the direction of the air flow, downward to the reflector.

As the

reflector heats, the local reaction rate in the reflector accelerates. As the local reaction rates in the

reflector accelerate, the reflector begins to consume all of the oxygen in the incident air flow. The

heating effects from the reaction are therefore beginning to shift from the top, where the reactions

- 27 -

begin, to the bottom, where they ultimately take place. The lines in the graph show this trend. Over

time, the heating begins to shift down through the reflector, and the air flow begins to carry heat

away from the pebble bed, which results in a temperature decrease in the pebble bed. Note that

oxygen concentrations were obtained from an analyzer located in the exhaust hood above the

experiment; therefore, oxygen from the shop where the experiment was conducted was infiltrating

the sensor at the time the experiment began. This is the reason for the initial peak of oxygen in the

curve. There were also potentially other difficulties associated with the preliminary test.

- 28 -

Thesis Goal and Objectives

3

The aim of this thesis is to develop a FLUENT model that simulates the German NACOK LongTerm Corrosion experiment.

This model will facilitate the benchmarking of FLUENT using

experimental data, once they become available from the new experiment.

3.1

Thesis Goal

The goal of this thesis is to develop a model of the existing NACOK long-term corrosion

experiment using FLUENT, and to use these results to predict the behavior of the reconstructed

experiment.

3.2

Thesis Objectives and Task Descriptions

The thesis goal will be accomplished by breaking it down into four objectives. Since the NACOK

Corrosion Test has very complex geometry, simplifying assumptions are required in order to facilitate

the efficient computation of results. Therefore, the lower, ceramic pebble bed will be modeled as a

single, continuous, porous medium. The graphite reflector will be modeled as an alternative porous

medium, with chemical interactions.

The upper, graphite pebble bed will also be modeled as a

separate porous medium with different chemical interactions, since the type of graphite in the

reflector is different from that in the pebbles. To ensure confidence in the results obtained, the

following objectives are set forth.

3.2.1

Obtain a Converged, Steady-State Flow and Heat Transfer Solution for Mesh

Refinement Study

After pre-processing the model, a steady-state solution of forced flow and heat transfer will be

obtained. This intermediate step to approaching a full solution is necessary to perform a simple,

computationally inexpensive, but nonetheless informative mesh refinement study. The refinement

study is discussed in Chapter 5.

3.2.2

Obtain a Transient, Natural Convection Solution

Once a fully converged, steady-state flow solution is obtained, the flow behavior of the model will be

switched from steady-state, forced flow to transient, natural convection conditions. Because this

intermediate step is not entirely representative of the actual experiment being modeled, this transient

model will be run until it approached the conditions of the steady-state flow and heat-transfer model.

The results of the transient, natural convection solution will serve to confirm the results of the

- 29 -

steady-state analysis by providing an alternative, time-dependent set of initial conditions by which the

same solution can be reached. Results are discussed in Chapter 7.

3.2.3

Add Chemical Reaction Phenomena

Once confidence is attained in the mesh refinement and initial condition inputs, chemical reactions

associated with the graphite oxidation phenomena will be added to the flow problem. This step

results in the creation of a computational model that comes close to fully replicating the actual

experiment as it is planned. The chemistry model will be used to analyze the experiment under both

steady-state and transient conditions.

Both the steady-state and transient chemistry models are

discussed in Chapter 8.

3.2.4

Perform Sensitivity Study of Chemistry

After successful creation of a chemistry model, a sensitivity study will be performed on the chemistry

behavior.

The sensitivity study includes variations on air flow rate, graphite temperature, and

chemical reaction stoicheometry. The air flow rate is adjusted by varying inlet and outlet pressures.

The graphite temperature study is performed by varying wall temperatures, and the stoicheometry is

varied in the chemical reactions template. The sensitivity study is also discussed in Chapter 8.

- 30 -

4

FLUENT Methodology

Despite the complex nature of this problem, a fairly straightforward method was employed. A

model will be developed using the Gambit preprocessor [20]. Then, boundary conditions were

applied using the FLUENT interface. Each chapter that is devoted to a FLUENT model describes

specifically what boundary and operating conditions were applied; this chapter describes the basic

methodology that was common to all models.

4.1

Develop Models in Gambit

Gambit is a preprocessing tool provided by Fluent, Incorporated. It features a Graphical User

Interface (GUI), which allows for the creation of complex structures by using simpler structures

called volume primitives. Once the structure has been created, a structured mesh was generated for

use with the FLUENT code.

4.2

Apply Boundary Conditions Using the FLUENT Processor

The mesh file generated using Gambit was then be imported into the FLUENT processor. Once

this task was performed, boundary conditions were applied. Materials used in the model, including

solid surfaces and gas compositions must be defined, and the appropriate approximations for

material properties were selected. Also, inlet and outlet boundary conditions were specified. As the

final part of pre-processing for transient models, the models were run in steady-state mode in order

to establish the correct initial conditions that the user had set in the model.

4.3

Run the FLUENT Code

While iterating, the convergence process was monitored carefully to ensure that there were no

problems with divergence of the solution, or anomalies in the code that prevented the attainment of

a converged solution. It was also necessary to monitor the number of iterations to convergence per

time step. Although the FLUENT User Guide [16] recommends that each time step converge at 1020 iterations, 100 iterations per time step were allowed because the flow is much slower than typical

cases modeled using FLUENT, and the changes in the model from time step to time step were

expected to be much more minute [21].

4.4

Examine Results

A thorough post-processing effort was necessary to examine the results. For the steady-state models,

grid refinement was examined for results of pressure drop, temperature contours, and flow velocities.

- 31 -

The transient models were examined to ensure that the energy balance is correct, that the

temperature contours matched those of the steady-state model after a significant amount of time, and

that the mass flow matched that of the steady-state model. After reactions are added to the model,

the chemistry was examined and a sensitivity study was performed by altering flow and temperature

conditions of the model.

- 32 -

5

Steady-State Flow Model

The first segment of the NACOK Corrosion Test model included a steady-state analysis of the flow

through the device in its corrosion test configuration, using air as the incident gas.

The main

objectives of the steady-state flow and heat transfer model were as follows:

*

Perform a computationally efficient grid refinement study,

*

Determine and demonstrate the solver criteria required to obtain a fully converged solution,

and

*

Use independent analysis to show that the initial assumptions made are correct and robust

enough to proceed to more complicated modeling.

5.1

Grid Creation

Prior to analyzing the model in the FLUENT solver, it was necessary to create a grid structure. The

grid structure identifies to FLUENT the geometry of the experiment, and specifies the resolution at

which FLUENT analyzes the model. The original grid was fully structured in order to ensure a high

quality grid. It contained 36 elements in each layer, arranged in a 6x6 square order. The elements in

the graphite region of the device were made smaller by compressing them vertically, and the elements

in the lower pebble bed, and near the exit of the device were made larger by stretching them

vertically. The original grid structure is shown in Figure 5.1.

- 33 -

7.734m

6.224m

e Pebble Bed 5.984m

ARefledor Blck

5.734m

Vold

5m

Perle Bed

nc Regeneurar)

Figure 5.1. Schematic of Grid Created for NACOK Model.

For the mesh refinement study, the grid was altered four times. First, horizontal refinements were

imposed on the grid to ensure that wall effects were appropriately modeled.

Then, vertical

refinements were performed to ensure that entrance effects were also modeled appropriately. Figure

5.2 compares the meshes used for the mesh refinement study.

- 34-

1

2

3

4

5

Figure 5.2. Successive refinements imposed on NACOK grid structure.

The baseline mesh file (2) contained 3,176 volumes, and a horizontal grid refinement study was

performed. To do so, a coarser grid containing 794 volumes (1), and a denser grid containing 7,146

volumes (3) were both created using the template from the 3,176-volume grid. The same boundary

conditions were applied to the models, and the results were examined. In order to refine the model

horizontally, the original 6x6 grid was refined to 9x9 elements per layer, and was coarsened to 3x3

elements per layer.

Since there is a temperature gradient in the lower, ceramic pebble-bed portion of the device, a

vertical grid refinement study was necessary to determine whether the mesh was sufficiently dense to

calculate the entrance effects consistently.

In the original model, the lower region of the device was split vertically into 53 regions, for a total of

1,908 volumes in the 6x6 model. There was no size function applied; all mesh volumes were the

same size.

- 35 -

For the first refinement of the model, the volume was divided into 90 vertical segments, with a size

function of 1.016 applied, meaning that each vertically successive volume was 1.016 times taller than

the volume that preceded it. This model had a total of 3,240 (Grid 4 in Figure 5.2) elements in the

ceramic pebble-bed region.

The final refinement contained 180 vertical elements, with a growth factor of 1.020, for a total of

6,480 volumes in the ceramic pebble-bed region (Grid 5 in Figure 5.2).

5.2

Regenerator Analysis

As another preliminary step, an analysis of the lower ceramic pebble bed was performed. This

analysis helped to describe the heating and flow properties of the lower, ceramic pebble bed, so its

characteristics could be correctly modeled using FLUENT. Ultimately, the goal of this analysis is to

show that the room-temperature air that flows through the lower, ceramic pebble bed exits the lower

bed at 923K for the 5-hour duration of the experiment. This independent analysis provides the

context necessary to conclude that the heating parameters established in this model are correct.

For this analysis, the lower, ceramic pebble bed was treated as a regenerator. This is because, in the

actual experiment, nitrogen was initially used to heat the pebble bed along with the rest of the device

(this can be thought of as a 'hot-cycle), and then room temperature air was allowed to convect into

the device, which had a cooling effect on the lower portion of the lower, ceramic pebble bed (this

can be thought of as a 'cold-cycle). Based on the two-cycle nature of the flow, the lower, ceramic

pebble bed is therefore treated as a packed bed regenerator heat exchanger for the purposes of this

analysis.

Since the cold-cycle, or the cycle in which the room temperature air convected through the NACOK

device and was heated by the ceramic pebbles, was the more significant part of the actual experiment,

this is the only cycle modeled in this thesis. Accordingly, only the cold-cycle is analyzed. The

analysis follows.

5.2.1

Initial Assumptions

The initial temperature of the entire experimental vessel was 923K; this temperature was attained by

blowing nitrogen (N2) through the device at 923K for 11 hours. Afterwards, a gas mixture simulating

air, entering at room temperature, flowed through the vessel. The incident mixture flowed through

the bottom experiment geometry, which is a 5m-high packed bed of steatite pebbles, and into the

graphite reflector and graphite pebble structure. Because there is an extended hot flow, followed by

- 36 -

an extended cold flow (see above), the lower pebble-bed structure resembles a packed-bed

regenerator, which is discussed in Mills' Heat Transfer [22].

It is duly noted that material properties of air are highly temperature dependent. To account for this

while maintaining simplicity of analysis, the analysis was carried out at an assumed bulk air

temperature of 664K, which is the average of the inlet and outlet temperatures (273 and 923K,

respectively). It should also be noted that the properties of steatite were not found to have a high

degree of temperature dependence.

5.2.2

Initial Material Properties

The pebbles are composed of steatite, a ceramic material, whose thermal conductivity in Watts per

meter-Kelvin is

k

=

2.5

W

(5-1)

m-K

The specific heat capacity, in Joules per kilogram-Kelvin, of the steatite is

rrr~

(5-2)

kg .K

and its density, in kilograms per cubic meter is

p

=

2.7

cm 3

-

kg3

2700 m

(5-3)

The height, h, of the ceramic pebble bed is 5 meters. Based on the pebble size and stacking

geometry, the void fraction is

6,

5.2.3

= 0.395.

(5-4)

Geometric Parameters of the Lower, Ceramic Pebble Bed

The specific surface area is defined as the ratio of the total surface area of the pebbles to the bed

volume, and is expressed in units per meter. For spherical pebbles, Mills [22] gives the relationship

a

=

6(1

(5-5)

dp

- 37 -

where dp is the pebble diameter in meters. For the NACOK pebble bed, the pebbles are 0.06 meters

in diameter, and the void fraction, as stated above, is 0.395. Correspondingly, a = 60.5m-'.

The hydraulic diameter of the bed, Db, is defined as the ratio of void fraction to specific surface area

[22],

Dh

=

(5-6)

a

For this bed, Db = 6.53x10- 3 m.

The characteristic length, j of flow through packing is based on effective pebble diameter, which, for

a spherical particle, is the actual diameter. For spherical particles,

=

d:

- 6v.

(5-7)

For this pebble-bed, the characteristic length is 0.0392 m.

5.2.4

Flow Parameters

We start with the superficial velocity, which is the velocity of flow through the bed if no pebbles

were present. This velocity, V, is dependent on the mass flow of the incident fluid, its density, and

the cross-sectional area of the pebble bed:

V =

(5-8)

pAC

For this bed, V = 0.0208 m/s.

The average velocity of the fluid flowing in the void space is obtained by dividing the superficial

velocity by the porosity of the pebble bed. This velocity, denoted by a script V, is 0.05253 m/s.

For flow in a pebble bed, the Reynolds number, Re, is obtained based on the average void velocity

and the characteristic length of the bed:

Re-

V

(5-9)

P1

- 38 -

in this equation, gt represents the kinematic viscosity of the fluid. For air at a bulk temperature of

roughly 618K,

p

=

29.74 x 10 - 6

(5-10)

m-s

Given this bulk viscosity, the Reynolds number for the pebble bed is 40.75; thus we conclude that

the flow is effectively laminar.

The Nusselt number for convective flow in the bed is obtained from an experimental correlation

given in Mills's Heat Transfer [22]:

Nu

= (0.5ReY+0.2Re).

Pr

.

(5-11)

Given an average Prandtl number for air of 0.69 over the temperature range in question, the Nusselt

number for this pebble bed is 4.91. Note that the Prandtl number varies only from 0.69 to 0.70 over

this temperature range. From the definition of the Nusselt number,

k

Nu

(5-12)

k

the convective heat transfer coefficient, he, in Watts per meter squared per Kelvin, of the air in the

pebble bed can be determined. In this equation, k is the thermal conductivity of air, which is 0.0447

Watts per meter per Kelvin [22]. Given these values,

h

5.2.5

Nu

-k 4.91- 0.0447 Wm

1 K

Nuk

K = 5.599

C

0.0392m

mZK

(5-13)

Regenerator Analysis

First, the flow thermal capacity, C, is introduced:

(5-14)

C - iCp,air .

- 39 -

The constant pressure specific heat of air, Cp, is 1038 Joules per kilogram per Kelvin. For the bed,

the flow thermal capacity is 1.1418 Watts per Kelvin.

Then, we consider the matrix mass, WM, which is based on the void fraction of the pebble bed, e, its

volume, which is the product of the cross-sectional area A, the length L, and one minus the void

fraction, and the density of steatite e, the ceramic of which the lower pebble bed is comprised, which

is 2.7x10 3 kilograms per meter cubed.

Wm = A(1- ,6)Lp = 0.09m2 (1-- 0.395)- 5m -2.7 x 10'

m

= 735kg.

735kg.

(5-15)

(5-15)

As a part of the regenerator analysis, a final geometric parameter is introduced.

The transfer

perimeter, denoted by a scriptp, is the product of specific surface area a and the flow cross-sectional

area A,.

o - aAC = 5.445m.

(5-16)

Next, the number of transfer units N, is defined. It is the coefficient of convection obtained in

Equation 5-13 multiplied by the effective transfer surface area, which is the product of the transfer

perimeter and the length of the pebble bed, divided by the thermal capacity of the bed, as follows:

W

5.599

Nt,,

hcL

2C

2~

5.445m- 5m

m2K

=66.38.

(5-17)

2.1.148W

K

Finally, the ratio of thermal capacity of matrix to flow RR is introduced. The ratio is the product of

the matrix mass and the matrix specific heat divided by the product of flow thermal capacity and

exposure time r, which is 5 hours, or 18,000 seconds. This ratio is expressed as a time-dependent

function by leaving r as a variable:

J

R,

1c

544,207() .

"

(5-18)

1.148-.r

K

At this point, it should be noted that the number of transfer units is very large, and that the matrix to

flow thermal capacity ratio remains very large, even at great exposure times.

-40-

For the five-hour

duration of the NACOK experiment, it can be assumed that, given a room-temperature inflow of air

at the bottom of the device, the outlet temperature at the top of the lower, ceramic pebble-bed

remains 650C. The basis for this assumption is a graph in Mills's Heat Transfer [22], illustrated in

Figure 5.3, which illustrates regenerator effectiveness as a function of the number of transfer units,

plotted for a series of RR values.

0.95

0.90

0.85

0.80

075

0.70

0.65

0.60

0.55

A

4f

V.-V,

1

2

3

4

5

6

7 8

10 12 14 16 1820

Number of transfer units, N11,

Figure 5.3. Regenerator Effectiveness Plot [22].

The graph illustrates that, given more than 20 transfer units and RR>5, the effectiveness remains

greater than 0.95. The effectiveness is the ratio of temperature differences in the regenerator:

Th,oui Tc,in

(5-19)

Th,in - Tc,in

The temperatures used in this ratio are the cold-cycle outlet temperature, T,out, which is the quantity

to be determined (this is the air that has entered the ceramic pebble bed at room temperature); the

cold-cycle inlet temperature, Týn, which, given in the Kuhlman report, was room temperature

(293K), and the hot-cycle inlet temperature, Thi, which was given as 923K (this is the nitrogen that

- 41 -

was blown through the device prior to the experiment). With an effectiveness value close to unity,

the cold-leg outlet temperature remains very near 923K for the duration of the experiment.

5.2.6

Regenerator Study Conclusions

At the conclusion of this regenerator study, it is possible to conclude that the room-temperature air

that is drawn into the NACOK device exits the lower, ceramic pebble bed at 923K for the entire

duration of the experiment. The air obtains the heat entirely from the ceramic pebbles, without any

external heating applied.

Because FLUENT does not explicitly model the pebbles, a simplifying assumption is required to

simulate this heating effect. This assumption takes the form of an energy source term, which is a

volumetric amount of energy that is added to the energy equation that FLUENT solves for the air as

it flows through the lower, ceramic pebble bed. The requirement for the energy source term is that it

contributes enough energy to the air to ensure that, at steady-state operation, the air enters the lower

pebble bed at 293K and exits at 923K.

The correct energy source term applied that met this criterion was 125 W/m 3 . The value of this

source term was determined by running steady-state analyses of varying values of source terms until a

fully-converged, steady-state solution was obtained that showed the influent air entering the lower,

ceramic pebble bed at 293K, and exiting that pebble bed at 923K. The remaining initial conditions

for these analyses are discussed in the succeeding section.

5.3

Solver Specifications for the Steady-State Case

To run the steady-state case, FLUENT was started in the 3-dimensional, double-precision mode.

Although the double-precision mode runs at a greater computational cost, the convergence behavior

of the solutions obtained is much better than with the single-precision solver. The energy equation

was enabled, and the flow was treated as laminar. In the steady-state case, only air was used, and it

was modeled as a single fluid, rather than a mixture. The result of this simplifying assumption, for a

steady-state model with no chemical interactions, is a computationally simpler model whose results

differ only slightly from that of a model that models air as a multiple-species mixture. This is

because FLUENT uses properties for air only, rather than averaging the properties of the constituent

species of air [16].

The temperature dependent material specifications for air are included in

Appendix A.

-42-

To reach a converged solution, under-relaxation factors were set to 0.06 for pressure and

momentum, 0.015 for density and body forces, and 1 for energy. These factors accompany the

Body-Force Weighted pressure solution scheme, which is identified as most appropriate for densitydriven flows, the SIMPLE pressure-velocity coupling scheme, which is a FLUENT default, and

Second-Order Upwind solution schema for momentum and energy. The residual convergence

criteria were left at the FLUENT defaults of 10-3 for velocities and continuity, and 10-6 for energy

5.4

Boundary Conditions Supplied to the Steady-State Case

In order to initialize the steady-state case that was run using FLUENT, the following boundary

conditions were applied. First, heating parameters were selected (§5.4.1). The porous regions were

then specified (§5.4.2).

Finally, the flow parameters and operating conditions were specified

(§5.4.3,4).

5.4.1

Energy Parameters

In accordance with the analysis performed in §5.2, a heating source term of 125 Watts per cubic

meter was applied to the lower, ceramic pebble bed region, which extended five meters up from the

bottom of the channel. Since the entire device operated at 923K, all the wall temperatures in the

device were set to 923K, as well.

5.4.2

Porous Region Specification

This model is comprised of three different zones that were modeled as porous media. First, the

lower ceramic pebble bed, then the reflector regions, and finally, the upper ceramic pebble bed, were

all modeled as porous regions. The specification of porous media is somewhat complex when

running FLUENT, and the calculations required are discussed below.

First, the porosity must be specified. For the pebble bed, the porosity is the ratio of air-occupied

volume to total volume in the pebble bed. For both the lower and the upper pebble beds, this

porosity is 0.395 as given in the Kuhlmann report [17]. For the reflector region, the porosity is the

ratio of channel to total volume, which is 0.189. This ratio is proportional to the cross-sectional area

of the flow channels divided by the total cross-sectional area of the reflector face. The total cross

sectional area of the flow channels is the product of the square of the channel radius (0.004m) and pi,

multiplied by 150, the number of channels in the reflector, and is equal to 0.00754m 2. The total

cross-sectional area of the reflector face is the square of its side length, 0.2m, and is equal to 0.04m 2.

The value of the ratio, 0.00754/0.04 is 0.189.

- 43 -

Next, permeability and inertial losses must be specified.

These are obtainable from the Blake-

Kozeny Equation, which FLUENT uses to solve the energy and momentum equations for porous

media. The permeability loss is defined in the FLUENT user guide as

D2

a =

3

(1 6

,

(5-20)

150 (1- c)2

where Dp is the particle diameter, 0.06m or 0.03m, and e is the pebble bed porosity, 0.395. For the

lower and upper pebble beds, the permeability loss was specified as 1/ac = 247,461 and 989,847,

respectively. This permeability loss is a scaling factor for the velocity of the fluid through the porous

medium, based on the size of the particles in the medium. Because the porous assumption is used

for the flow channels in the reflector region of the model, but the flow channels region isn't explicitly

a porous region, there is no permeability loss. It was therefore specified as zero.

The inertial loss is the physical resistance to the flow imposed by the porous medium. For laminar

flows through packed beds, the FLUENT User Guide recommends a value of zero, and was

specified accordingly [16]. For the flow channels, the inertial loss should be extremely large in the

directions that are perpendicular to the channel orientation. Therefore, an inertial loss of 5,000 was

specified for the reflector region in both the x and z directions. In the y direction, there was no

inertial loss specified.

The number 5,000 was obtained from the recommendation in the FLUENT User Guide that the

inertial loss in a direction perpendicular to the tube orientation be between 1,000 and 10,000 [16].

5.4.3

Flow Parameters

To execute this model, an initial mass flow of 0.00185 kg/s was specified at the inlet, normal to the

boundary, at 293K. The selection of this value bears some discussion. The Kuhlmann Report [17]

indicated that a pipe cross-section reduction was used on the preliminary corrosion test to restrict the

incident mass flow to 0.0011 kg/s. However, in the Zhai CFD investigations of the NACOK Flow

Tests [19], the test that employed a 600K difference between the hot and cold legs had an incident

mass flow of 0.00185 kg/s. Because Zhai's investigation did not use a pipe cross-section reduction,

it is assumed that 0.00185 kg/s is a more realistic value for the mass flow rate. Therefore, in

investigations of the corrosion test, initial values of 0.00185 kg/s are used for mass flow, and when

pressure differences are used, mass flow values in the range of 0.0016 to 0.0020 kg/s are expected.

- 44 -

For the first series of iterations, the outlet was simply specified as an outflow with no further

specification.

After the first series of iterations, the inlet and outlet mass flow rates were maintained and

convergence was obtained to calculate the pressure drop. With the pressure drop calculated, the

boundary conditions were then changed so that the pressure drop was specified, rather than the mass

flow rate. The proper conditions were a pressure inlet with zero gage pressure, and a pressure outlet

with a -14.67 outlet gage pressure. This was the calculation on the mass flow computation.

After convergence was obtained using the outflow, the outlet condition was changed to pressureoutlet, with the total pressure drop specified as the outflow gage pressure. In this case, it was

approximately -14.67Pa. After iterating the model to convergence using this condition, the inlet was

changed to a pressure inlet with zero gage pressure. The model was then re-iterated in steady-state

mode to full convergence.

The change from outflow to pressure-outlet causes the steady-state flow and heat transfer solution to

converge faster. The reason the outflow was first chosen, however, was to determine an initial

outflow gage pressure to specify at the pressure-outlet. Also, it is necessary to specify an outlet

pressure when modeling flow in a transient condition using FLUENT, because an outflow boundary

condition paired with mass-flow inlet is unacceptable for proper transient solutions [16].

5.4.4

Operating Conditions

The device was set to operate at atmospheric pressure, 101,325 Pa. A gravity term in the y-direction

of -9.81 m/s 2 was added to simulate the gravitational force on the coolant. The operating density

was not specified.

5.5

Results of Steady-State Analysis

Figure 5.4 shows the contours of static pressure. FLUENT defines the static pressure as the "gauge

pressure relative to the operating pressure."[16]

Therefore, the inlet at the bottom of the flow

chamber, which is where the operating pressure is referenced, has a static pressure of zero. As the

pressure decreases vertically through the device, the static pressure becomes negative. In the region

above the upper, graphite pebble bed, there appears to be a rise indicated by the contours of static

pressure. The pressure changes from -14.59Pa at the transition between the upper pebble bed and

the void area at the top, to -14.48Pa at the exit of the device. This 0.11 Pa pressure increase, when

compared to a total pressure drop of 4.43Pa for the graphite pebble bed region, can be considered as

-45 -

negligible.

It is most likely a continuity compensation for the flow development and resulting

velocity increase, which is described below.

nUUU.

nn0 UUnn

-7.50e-01

-1.5 0e*0 0

••l

Ulpper

-2.2 5e+0 0

-3.0 Oe-O 0

-3.75e,00

Upper Pebe Bad

PcAmI'e

Ulaer

BIWAt

srclk

es

-4.5 Oe00

-C,

9r.,.+a

(ower

teMr

w name el0Rnem

-6.0 Oe*00

-6.7 5e +00

-7.5 Oe*8 0

1. CGnW

2. Mhium

3. PhMt

-8.25e00a

-9.0 Oe'00

-9.75e*0

(mrwe MG aninMM):

(made lo #2 aboie):

-1.0 5e,01

4. Iman

s. Fler

-1.13e-01

-1.20e'01

-1.3285e01

-1.4 3e*01

-1.50eOl 1

12345

FUENT ConaUn of IS Premie (PA)

Grd Aeusem Sudy

MAClK Smot-Stm Cm

Figure 5.4. Contours of Static Pressure.