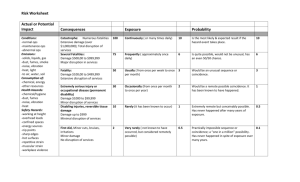

Risk from Network Disruptions in an Aerospace Supply Chain

advertisement