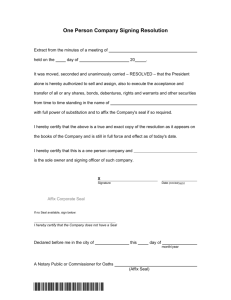

AN INTERNAL SEAL FOR NATURAL

advertisement