Iftssaalmsetts Institute of ",'Technology

advertisement

, $ 1

,141

%

1L i i3

7TT'. CL=ING

OF

PITTR

LEA4"TT

SOLUTIONS

BY

CAMONATE.

OP

T717AIV-7

lightsthesis Is submitted to te vacuity of the

Iftssaalmsetts Institute of ",'Technology

in partial

1alfillment of the reqairements for the

Degree of Bachelor of Science

In the Departmentof Metallurgy

by

In the Departmentof

ectrochemistry

by

11Z1-

71--

I"

Cambridge,

Maso.

June, 1926.

.

I

19ff

Agipowledir,wnt

'".

We wish '.,o thanIt Pofassor

Carlo R. 7ayward

for his helpful recommendations

ad suzgestions for

methods of attack

olt

We wioh to

help in olving

the subject.

46

B. B. Trsmare for his

of anal7zing solations.

We wi5h to thank i"r. Laist,

Mr. William With,

Sr., for tir

11r. L"Lton, -nd

recomnendation o.

this subject 10brthesis .,fork.

.

-

.4

.

i.

INI

Z)

Za_js of vlontoLt s,

Page

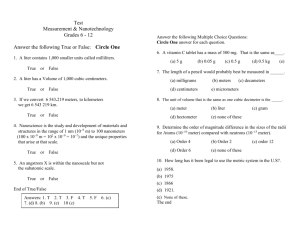

Purpoise.

1

Introdue-tiou

to C*ar Wozic.

3

Uethads of Analysis.

5

Precipitation.

a

Elsetrol,7sis.

9

Procedure.

Discussion

10

and Data.

I

-1I

0cne I Uzct

I on s .

17

ROCOMMOU&1t

ions.

is

3 I b 1 o grap 1,,7.

20

I

1'4 arpose of tlAs thesic I, t etract t

ipurities

(iron. arsenic, ant1mowj,,phosphorus, aluzin=) that are contained

in the solution resultin

from te leaehitg of a copper ore with

a sulphuric acid olution to such an extent that they do not

effoct the onrrent

fficiency and character of deposit in the

subsequentdepositiot of te copper by lectrolysis.

This state-

ment a be modified b7 confining the elimination of Impurities

to Iron. Iron is the most troublesome im

L

puritybecause f its

corrosive action on cathode op per.

(Arzenic and antimony would

also have a orrosive atctl= on the cathode copper; but since it

Is carried downas explained later,

t

an nowbe disregarded.)

This limination is effected by the precipitation of the iron by

means of

alcium carbonate.

The one uessful

method in practice of reducing the

corrosive action of Iron Is the use of "2 as a depolarizer.

This

method is nowued 'by the largest loaching plants in th wrld,

(DowOornelia, Chile 03opper) The solution Is ran into

towers

where tba S2 is absorbed. Lhe ferric iron s red-aced to farrous

iron-, and S2 is Osorbed by the solution, and acts as a

depolarizer In the aell hse.*

of Imparitles by this

ethod.

There is-no actual precipitation

It is -necessaz7to constantly

4iseard solution to k"r the i=uritiez

*Iawrenae, -'*rans. -m. Electrochemical

Ricketts,

Trans.

A. 1. 11,%

Vol. LII.

below a point role

Soeietg.

1.

r

tbiey

2

will

nterf"Ore with electrolysis.

h

Is done by aattjmj out

a Contain =ount of Solution -after it hAs passed tmugb

t1'9

cell house, and ten pr6alpitating, the copper on serap iron.

Oho rasultinf;

copper

evolution is thrown away

has to be malted.

T

remating

In brief, it meanstt

constant oss of solution tat

cement

there is a

is hgh in aold ad an added

pense of handling and smeltW5 Oement opper.

11!

1_nt;:o4uqt12n

to

I

r ,;or_.

1.0

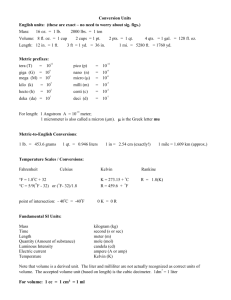

The solution used I r this workwas made p synthetically to correspond to the solutions that are obtained in

leaching copper ores at the Andes Copperlompany, M19, 5outh

America.

Anal7siz of solution resultingo

ore

rom leaching

t the Andes (copper onparq:

OU

R,2SO&

Totai Fe

-Al

As

Sb

40 gra= per liter

10 omms per liter

6-8 grams per liter

5-6 rams per liter

gggr=sper liter

.08 ram per liter

P,20,5

1.3 -==a per liter

Sio

.59 gram per liter

_Amlysisof sthetia

GU

'H,2SO4

Fe

FerrOUL Fe

Al

P,?05

As

"'S

13.9

6.2

0.4

olutiont

grwas per

Sr.ams per

zc,,rawper

-,= s per

liter

liter

liter

liter

3.0 E-,

rams per liter

1.2, r,,rms Tor liter

1.1 grams per liter

These substances were put Into solution in te

following mmmer:

Gapper

Iran

Al=inuM

Ar"nia,

Pbosphorus

Ca S704 W_20

PWS04M,20

A12(SW-9H20

A8203

P;205

opper

A

It

Tvss imzossible to Lot antimony nto a d1lutq HZS04

solution wlthout bmavii..',it In the formsof a complex i.rcn mith

tartaric acid.

",Inca the antimony acts 44

did ,,lot deem

advisable to attamrt I,,- Castit Into solution

tl,.e asa of tartaric

ame as arsarJc -me

acid bcause of the chance of the

tartaric acid holdine, p the Iron in precipitation.

not added because it does not effect the

Considerable difficulty

!ray.

roblem in any --

xas encountered in getting al=imum Into

solution because of Its golng In suspension.

days, the aluminum settlqd

off and stared for ue.

71.1icawas

()n standing Several

out and thq clear solution was siph=e1,,.

5

1

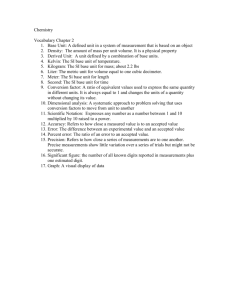

M'011104g

S

C2MPx.

Procipitation by alumin=.

DDissolving with

NOZand taking

it down

th Y.Cl and

R2SO4-

St=dard iodide method.

Reduce ,with al=inum.

Titrate

1vith MftO4.

Farm'sI=.

Me

analvis

suggested to s 7 the Inspiration Copper

CorVany was as follawss

1110cc. solution

,water,

in 250 cc. beWkor.

cc. oone. 142SOA. Titrate

Add 5 co. distilled

with

Wefo=d that his method as Impossible because of

the interference of te oopper. The rult

,,wre ferrous Iron than the total iron.

for ferrous iron gave

then tried the bichromate

method, 'out here again the copper interfered with tl,.e ona point.

After sveral

days of exparimentation, and as a last resort, we

preelpitated the Copperas cuprous xanthate and titrated with

biahromate solution.

ing o-ar matrix, It

fince there as nothing In literature

as necessary to ran blank tests.

oncern-

A olution

ruide up of

,Franc Ou n.--,r1.00 cc.

10 CC. of --standard 1errous

sul-bbate solution ras added. rhe solution .wasa-aldifted

5 cc. of cone. F-01.

be clopperr. wasprxipitatodwith potasslum

xanthate, and 41.-he

filtrate

-s

t1trated with bichromte.

mothodohealked,so, t.

thyl

This

plied It to our

,,withrenz=ble security.

Aluminum.

Iron oxidized with a few drops

o1O

7-ITOZ.

Iron and alumlr= hydroxide precipitated

7 e=esz

W40H

Filter,

Imite, and weigh, as Fe2O3+ A20-3.

Percentage of al=l=m dtermined by deducting

known amoumt of

e2O3:.

AxsMI&,.

Precipitate fromhot solutionrith hdrogen mphide.

Dissolve in sodium polysul-phide.

RepreC4

pitata arsenic as silver ron.

Ignite and iseigh.

" Shama.

"law filtrate

from above HpSprecipitate

and precipitate

with- ammoniummolybdate.

Reassolve in aecida=nla

Rsduce in -Tonas rducer

e13te

and titrate

*fty, Azantitative Analysis, We 75.

slution.

with Mta04.

0=sidarnble dilt'riculty,

eiicountered in maalyzin,

due to tha amphoteric character of aluminum.

Precipitate

Filtar

Cu by K

d

S203.

,Lmdreduce llodiie b7 Na2S20.3.

Filter aain.

Tilrata wth WI=

Indicator.

carbonate -7l-'.'-hethyl orange as

6

The apparatnas sed for the .,:recipitation

described as follows-. The aitating

,,rill be

chamber as a ton liter,

,narrowm=thed bottle with the bottom out off.

This was

Inverted, and -air as led Into It by means of glazz tubing

through a rber

for tho ir:

topper.

There were two serarate

one terminating In a anvaz bag flanged around a

woman's ommon mbroidery hp;

bottom of te

distribute

entrance

coutalner.

and the other at the very

The canvas bag served as a means of

te air througlicmt

t solution in flne bbbles,

and te other Fred

the neck of t1habottle.

the settlineof te precipitant at

The Inely dirided air n-- only

served as a me=s of agitation,

'but

so as -an oxidizing agent

Itor the iron.

T'he calcium carbomate used for praclpitating

the form of marble crashed to 70 mash. The

content was 4

r cent.

The filtering

Bueabner fillar

lei=

was In

aar6onate

a.

of the solution was done n a large

through filter

paper.

9

-A

1.1110

eloctrolysis

jam,

seven Ignores dp

solutionma-s alr=lated

was done in small suare

and three and one-balf

eass

nches

b means of a Poble air lift.

de

Te

Vie

anode wre lead -andthe cathodes thin strips of copper. The

size of the alectrodes ms fur t3ndone-half inabse by t=- and

one-half Inches mabnerpd.

A copper caulomtqr

az connected in

series, with a solation --onalst1w of 1000 gram of water, 150

grams of coppe

50 gmms of

5ph-ate

lcohol.

=7stals,

50 grams of cone. HZS04 ad

10

:PXqcsdur,i.

Six liters

each ran.

ol the s7nthetia solution wer tken -.

VOr

Te amant of 1mroex

neutralize the

used was 171Cared, first,

and second, to procipitate

id,

carbon-ate. The vol-ation mz aigitated fr

11marockblief addedduring the first hr

fifteen

Two lters

inutes.

o

'kphe

Aftor rigitation

the iron -as a

two ours, te

at Intervals of

he ,Evolutionwas altered.

-1L.

I'lltrate -,7aretaken for -electrolysis.

aurm-nt afficiancias

to

The

and deposits of a pure opper sulphate

Solution, an maleaned solution, and a cleans. solution, were

taken ,md ooMareed. The lectrolysis

two hours.

alachol,

as run for period

Vae athodes -sere t1hen tmken out, mashed with

dried, and treigbed.

The res-ulting ftltratas

were analyzed.

of

11

Discassio - nd Ata.

Therm=nt- of CaC% used in each ran was frst

e1gured as fllows:

Basing It apon the original analysis - al'O3fjor acid.

15.9 gmms per liter.

T42-504 CaCN

-

CaSO&+ H,20+ 002

U-2 x 00

=

14.2

rams OaC-0, rer

I

98

We added 25 gran

f

liter.

C0 I

17hiesolation Davis

agitated for to hours. Upontrying

to -1.11torIt, we ound hat It would not flter

ax-parimenting we found tt

by heating

cold. Upon

Cha solution

the precipitate coagnlatad o that V wld

flttr

to 55-60' C.,

radily.

In

All of the follo,,,winj runs -his procedure waz followed.

This 5olution was ther-aal7zed fr oopper and iron.

Copper

Iron

34.1 Sr:wm pr

liter.

3.8 grams per liter.

From theve results

we aw that more OaG03was

necessary to eliminate all of the iron.

than the ori-ginal solution.

T'hecopper was hgher

This Is undoubtedly due to

evaporation during agitation =1 water chemically combined.

Thiswas found to b the case in all of te following r=s.

,Wethen figared fr= theoretical amounts, and iclude

the *eraentar prity

of marble 54 pr

ent.

aO) the exa-at

az=nt neceszar- for the acid, 14.5 ,ramper liter.

12

This jeaves 10.1.3gmngspar liter

to precipitate 4L-Ihe

iron.

the Pollowinf,-.ealaulation.-, i-t Is

evider41;

From

Iron to-es down

Chat

as -farric aarbonate.

+-;--

2 Fe

+

CaC

N

.

Fe2 (003 3

Ca4-+

ffIere was 62 gram of iron in tho original

and .8 In the final solution.

This lavened .4 glim

olution,

tat

we"

pre-a iDi tated.

Fromthe raction

=1

o Ir= and GaMo tbe, following

4oulations are 'baead.

4.4 - x 300 = 67 grams per liter pure Ca(z.

x 55.8

which corresponds to 68 grams of marble. h, plus the 14.5

grams for the acid, givess 21.3 S=s per liter.

The difference

of .7 rams an Justify be credited to losses or praci-pitation

of alumin=.

Basing our *nl=lations

on the above discovered facts,

we added, in the following runs, On U*oretiml amount of

marble eds.

In al. probability te ferric arbonate is immediately

h7drolized to ferric Hydroxide.

Obser7ing the same conditions a

and filtration,

marbl e.

we =d

to agitation,

a ran with 35 gramsper liter

time,

of

13

Analy.Is ol' filtrate:

Co-o-

4

,.-er

35.4 rrams per

'-

Iron Total

Ferrous iron

0.91 z;ramper liter

.63 ram per liter

.Alwairmm

2 1 fgrams per "Iter

Arsenic

:05 gram per 11iter

P20.5

.20 sram per liter

A Discussion as to how tiie impurities

ome down at

tlh.is point -ight be dasirnble.

(As rgards the fom of arsenic In sol-ation

r.

Laist, in parronal commanication,said that arsenic Is in the

farm of rsenic sulrhate.)

Ths reactions as far as Iron is concerned:

(1)

702(SO4)3

3

aGO

3

+

G0(C03)3

With excess acid this beocoes:

(2)

?02(('03)3 +

4

$-

*504)Z

+

H,20+

COP.

That is until the excess acid is used up. flhau, ith

oxcoss li-ne,

ou get reaction No. (1).

The ferric

arbonate, vould then hdrolize.

Angnio.

AzZ(SO4)3 +

92(CO3)3 +

HZ-0

2

ot +

(Antimonywuld likewise blieve this way.)

CaCO3 + 02SO4

=

SQ4

HP-0 + COZ

Hso

+ z

o2

14

The elumimmwill likewise be precipitated i

t

same

ma=ar as the Iron.

Tbase equatiams may or my not be rieit,

if anyone can disruto tunNbecauz

'but vooaoubt

o a lack of knowledge on the

Subject.

In aalyzing the results obtainedIn this

,

1t mm

dafinlte17 be concludedtat thic methodof purification -will

lower the mpurities to such a point that they aan be onsidered

negligible.

By t,

request of Professor ft-vard we madeup a

solution f=1 in Iron 30 grams per lter)

mad madea rum 9=atly

as before volth the exception o-t lacreasinS the agitating time to

three hrs.

In this solutio

fOrmW. More ifflmlty

60 degrees C.

obtained.

a heavy, dense brownpecipitate

was eemmtered

ter filtering

In filtering

twice a clear filtrate

even at

was

The amo=t of marble used was figared Zr= the theoretical

value eqaired.

This amount as 100 g=s

per liter.

The solut1cm,was analyzed for Iron, =d: for cower.

010ppe'r

Iron

The rults

33. 8 gra=

2-.0 ram-

of this ran how tat

takan out of solution by the Mcipitatiou,

the copper as not

and that the Iron

-wasreduced '., a point thAt would not interfere with the

electrolysis.

I El

in obtaining the current eff icieney and ttl'ze

abaractar of te dposits,

runs were madeas stated previously.

A curran't density of six aVere

a

pr square foot was ased !:-tt

twmperature of 50 dgrees.

Th-,,fi-st solution -jas a pure copper sulphate

sol-ration

32 STams of Cu per liter,

anodes were used and

e athode

and cathodQ was two inahez.

electrolyte

as

h

R2504).

runs were 91.0 per cent. -and 89

Two lead

intance betweez anode

The -rate of circulation

7 cc. per mute.

bright, amooth, rystalline,

10 -mv

The affialleneies

per eent.

of

on two

The do-posit mas a

anti solid de-noelt.

The origizial impure solutian gave an afficlem

of

87 per cant.

ne deposit was In every rerpect similar to tho

above deposit.

rivers heck-- up airly well with What Vr. .

gives as his fndings.*

Mr. Eagle so," ttat iron below 65

grams per liter does not efect rmterlmlly te

the deposit.

nis

fficiency or

mi,&htbe explained 'ay the aluminum In the

solution atting as a diaphragm, or, n other ords, it h

regard

effect on the

crroziva tandeney of Iron,.**

The electrolysis of te fil-trate of ran Ro.

results as good as the pure ooper --alphate.

of this Is unecessary.

*Ifrana.

*1'11

Trans.

AM. MIOM. Soc.

Am. Chem. I',00.,

a

Vol.

Vol.

XLV, page 372.

MITI.-1 iddicks.

gave

Parther discussion

16

Mbeeeetrol

per

is of te solution containing

40

am$

ter of Iron gave an offlaimay of 40 pr eont. and

the dposit

was peroeptMy earroded as evidenced 17 ftrrms

*-r ;Streaks..

adw

17

Ts liesitate to give any definita Oanclusions about the

practicability of this mthod of al"aing

opper leach solutions

because of the Limited scale upon which the work was conducted

and the manypases of the subject tat

ave not been Investigated.

Rlowever',

'weare -certain, from our results,

principles of tbe subject, precipitation

tat

the two f=damontal

and 17ilterine, may be

effectively a*ao:V1ir1,-ed. To are further convinced of this by

tire fact that In the zinc leachin-g at Great Falls, Montana, at one

time, the pecipitation

of all of the iron in the zinc solution tms

accomplished by means of lime.

It is foolish for 'as to make an

attempt to arrive at the ultimate cost of the process because of"

the small knowledgeof the ultimate factors entering into the cost-,

but due to the cheapness of limerock

and its wide distribution

4q..2 a ton trough

65 mesh)

throughout te world, we are convinced

thatthe process is worthy of Investigation on a large scale.

we had started on our thesis we larned

After

that patents had been taken

out on te use of 1mernak for cleaning copper leach solutions by

Mr.'Lalst of the AnacondaCopper Oompavy. Since the ubject of

research was recommended

t us by officials

of te AnacondaCopper

Company,1mare aiting with Interest to Core

obtained.

the ramlts

18

.got knowing the details

of the-rrork Carried on t

Anaoomla, we reoomend the followine invos,-Lgations, providing

they have not baem already carried out at Anaconda.

Alkinly, e=erimentation

and practicability

n a large scale with the cost

of the apparaturs in view.

This Includes the

following$

onsiderine the amount of lim rack and the time of

(1)

agitation, we reco=end tat

a thorough investigation be arried

out to obtain '-,hebest economi*al balance bet-wean te

two.

(2

A ractical

means of agitation.

(3)

A study of the rost economical temperature to heat the

solution to in order to filter.

Bore w -mightstate tiat the

cost of this factor Is not ofgreat

Importancebecause the

solution ,vnz to be heated to 40 - 0 degroos . for lectrolysis.

(4)

An adequate and suitable means of -A"11tration. -its realize

that the precipitate Is large and bulky and tat the tne of filter

should be one having a lar,,,-e fltrating

readily washed. We recommendtt

area

nd one tat

ocrald be

the iloors type of filter,

h

as is used in the oyaniding processes for gold be investigated.

This filter

bas a large area, and it can be readily

washed. In usin,-:; our canvas bag for agitation

became stiff

and hard.

If canvas flters

a study of re-conditioning these filters.

andled and

we noticed that it

are used, we roe-ommend

19

(5) A study o-f tho Wash1ng of the nreeinitats

included copper olution,

to recover

We racorrmendhere an ivestigation

the use of limOrock to precipitate

of

the copper from the wash

,,voters as a arbonate.

(6)

'the working out of a onti=ous

process without tho

lose of any solution-or the us-9 of an additional

,W of t

rocess for

products such as the 1kindling,of' cement comer i

$02 process.

te

Webelieve that the precipitated eopper arbonate

from the wash solutions oonld be ten

with the excess limarock

and placed in the solution before it has been leaned.

Therg the

copper would be takez Into solution and the excess 11marock would

be 'used In the precipitation

of Impurities..

In no way can we

son where there would be a loss of solution in this process

We

reallse that the acidwould be neutralized In the precipitation

process, but sines te acid content at tie

point is so small,

this lose would not be of reat importance., and in comparison to

the SOZprocess, the loss perh4ps would not be greater tan tat

lost in their discard anlution.

Water ,wouldbe lost from the solution b7.evaporation,

chemically tucluded in the precipitate,

precipitate,

mhanically

included in this

loss due to Includedwater in the tailings of the leach,

and atural mchanical losses darimg the process.

Mis loss could

be made up from the wash water, so only the excess immsb ater

hare to be stripped of copper.

ould

20

Hofmanand Haymrd,

"Ketallursy of 11cpper"

Trans.

A. 1. K. E.

1914,

XLIX, 610,

7rans.

A. 1. M. E.,

1915,

LII.

Rickatts

7257,

Iforse and obleman .

Tmns. A. I. M. B., 1916, -,

Toblew==d Potter

Trans.

A. I. M. B.,

1919, LX,

Trant. Am. Bleotroahem. W.,

80,

2

191s,

mX711I, 73,

Addl oks

Trans. Am.3100troebem. Sac.,

Zern

1918,ImIll, 11,

11"Mans.

1924, -ZVO 65,

Am.

Meatrecham

O$

Eagle

mns.

Am. Electrochem. Soe.l.

19,24,

XLV,

53,

Skowronski

Private 00mmmicationwith different officials

-4=aconda Copper Company.

of the