LIBRARIE1 Author . r*..

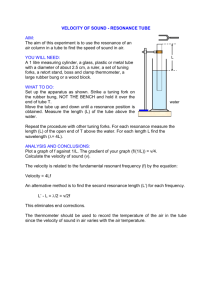

advertisement