. *

advertisement

JUN -121It

DYNAMI

STABILImY

OF HYDRAULIC POPPET VALVES

by

Jens E. Jorgensen

S.B. Massachusetts Institute of Technology 1959

SUBMITTED IN PARTIAL FULFILLMENT

OF THE REQUIREMENTS FOR THE

DEGREE OF MASTER OF SCIENCE

AT THE

..

_.;

...

. ..

.*

/ * .*

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

May, 1963

Signature

. ,;..

of Author:.

Dep

tmenchlnical

Engineering,

May, 193

CertifPied

by:

...

... .

.. ,

.

/'

.. .

. ...

.

Thesis

Supervisor

Chairman, Department Committee on

Graduate Students

ii

DYNAMIC STABILITY

OF HYDRAULIC POPPET VALVES

by

Jens E. Jorgensen

Submitted to the Department of Mechanical

Engineering on May 17, 1963, in partial fulfillment of

the requirements for the degree of Master of Science.

ABSTRACT

Stability criterion for a hydraulic poppet valve

have

been analysed and experimentally verified.

The analysis were based on the linearized equations.

and on this basis a stability criterion for stable

operation of a hydraulic poppet valve as a function of

valve position and upstream geometry was formulated.

The validity of the equations developed were checked

agoainst an experimental

Thesis Supervisor:

Title:

model in the laboratory.

Shihn-Ying Lee

Associate Professor of Mechanical Engineering

i-i

ACKNOWLEDGMENTS

The author wishes to express his sincerest appreciation

and irndebtnessto the following individuals for their contribution towards successful

ompletion of this

roJect:

Professor S.Y. Lee, thesis advisor, for introducing

me to the problem and for his helpful guidance and construct ive evaluations.

Mr. Kermit Harner for his sincere interest in the

problem and constructive suggestions.

Mr. Karl Reid and all other members of the Engineering

Projects Laboratory for valuable aid given whenever needed.

This thesis was supported in part by a Grant in Aid of

the Hamilton Standard Division, United Aircraft Corporation

and sponsored by the Engineering Projects Laboratory at

Massachusetts Institute of Technology.

.1iv-

L-r

i-

T

irL TTRAp\ TO NT S

t a i.

-

oe

;

ont

y ro vo

heorti

l1 stti-

lume

.

Gener:,lized

.a

..ion.

. .

.

i

'?ressure

f'or-e and

vs.

yc ev::tv

m7mW

o iOs s,:o01

lr ....

.

.

sysr em response ....

Dimensionie

.......

ln9me

rT

.-...9

Combinedeffect

1n

ead

vs.

r9!

·KJ

..

................

o...

models .....

b

.....

23a

v ve posit in.

3

30b

ind TR......

Downstream

yt

:omressibi

lde r

........

Stati

oe of resure vnd

t it,svic poe

force

'nd foce

oopetvis.ace

:osition

............pressure vs.

.......... 32b

P ase ag

of presure and orce

v.ive freqency

..........

nd

.

4

1 b

onstant vs. pressure......

ame

.......

..

2-12

com : ressibit

s s,

'3

_-2

g

v':, owen

2-3

- 1i

7h

nstant

oe .......................

n inge

Dimensionless

l: ime....econstant

oTopetv- e oen:ng

... vs.

.ooet

?

o

time

_o peJ v-ie

C6....

12a

&iYstern mode

2-7

e

Sytem de cra?tion

:yt

-4

ia

T=asa

e Ug

fr~equemc,

ofD!essure an d

of

Lo ncd

-7

Expe imentail time Ig

-:

La

vs.

Jfe.ts (summary)..

*force

s.

.

vs.

.,3n

oopet

oasitnL

t

33c

d

Z*lq9

t

..

?f

1 ut t:r

tis

i

t

d.

F ' . u re:

3-

.. se -ead 6 of measure and fore

V I.f e.uency

31L ne

nd P......

4.

I - d e,men

vlve position,

ffecs

onstint

vs

o

(ex· eriten

)

3-q

Lead

3-10

Oytem

3-i_

S.ystem stabiity

vs.

System

stability

vs. valve

j-o

stability vs.

Dynamics

B-

OComuter ogrm

D-!

OrLfice

of

35b

.............

35c

ressu-rIe and disvoiume and

ositon..

1L

osit on .

.

37b

37b

37c

39s

'ine...........

48

schemtic ................ 7

flow coef:ficient Cu vs. Reynolds

i

Nozzle (

Reynolds

Viscosity

65a

.0

o.a90 ° ) flow coefficient

no.

n vs.

....

..........................

b

-00 )flow coefficient Cn vs.

Nozzle ( c

Reynolds

D-4

et

rpar:tus.

B-I

D-3

35

(summay)

k- S hemati2 of

D-2

s.

.-

*

no....

........................

s. tem:e rature .........

o

11

,- i

NQOMENCLATURE

f

-ymnboI

ion and Unit

Descr is..ti

*:re: of the Line L ( n')

A

ar'ea

C7

2oe ff ient of damning (Lbs-sec /in)

j

di,;meter of line L and nozzle di meter (in)

F

poppret forcee (lbs)

f

valve frequency (s)

G

valve

K

spring rate of external sring

K,

ressure gain (ibs/in

oppet flow

3

)

(bs/in)

with disl a cemrent (in 2 /se c

ensitivity

KQ popoet flow sensitivity wiSh pressure (in/l.bs-se

K3

upstream orifice

K4

poppet downstream flow sensitivity

K5

downstream orifice

( n//l

bs- sec)

L

length of line

M

mass of poppet

P

fluid pressure, aiso

of the -poppetvalve

C

:Flow rate

T

time for wave

9o

system upstream volume (in

f ow sensitivity

with pressure (n/lbs-sec

with pressure

(in'/lbs-sec)

volume

flow senS tivity

with

resure

in)

(ibs-sec 2 /in)

through

ressure immediately

the poppet

to travel

(in3 )

;V

fluid velocity (in/sec)

X

valve

disrlacement (n)

)

pstre-m

(ln3/sec)

the length of line L (see)

UI

a%'

-i r

Nomenc I -t-ure

continut-d.

ae

ion nrd

ri:g-t

De s

Symbol

pO(

pet

cone ha lf

ina

UTnit

e (der .)

P

er

c-h.se a, betewee

(0

fluid densit

,P

/3

ffl-uidelasticity (psi)

teLe

nd fore (der.)

ert

)

(s-sec/n

kinenmatic viscosity (inS/se)

R_

VD

3> _

Reynolis no

()

nondimensional valve dislp .cement

A

Av

Au

nondimensional valve displ-.cement

t

valve time constint (see)

60

v:ilve frequency

incremental

D .

dt

(rad/sec)

chinge of

v-,riibie

differential operator

SubscripDts:

o

mean or time -Lverage condition

s

supply condition

v

vive - ref.

u

t ion

ustreamm ond

R

-return condition

I and 2

refers

of a vriable

to poppetvve

to sections

I

nd 2 (adjacent)

TABLE OF " ONTENTS

I.-,'0

INTRODUCTLN......

....

. R

DescriotiGEMonS

A

NO~ENfr

vii

.....

B Bckground

...

1."20

Con lusion

I.0

Recommendations

TAnRT

II

. * *........*

.....

i

4

.......................

ANALY ITS

S

2.00 introduction..................

-.0 Model and 'ystem descriotion ................

2.20

Static charcteristics

nd s

tbiity........

0.

!0

..

.

'2.30 Dynamicstabilty.

?.40

2 .5'*0

the

onoet .........

10

?.31

Forces

2.32

General stability considertions ....

on

Compressibiiity model ......................

.

41

Dynamic

1

Stib

-

12

16

quation

......................

t

y

*19

.

..

Inertia

model....................

tion

i51 D rnam~c

c--u

.o.......20..

'.-

otabi

.i y..

.....

12

.T

" on:-nt s

I'

orin-nued.

...

2

mbned

;,.s

.

. ......

efes

·

DiDynami - e q u,a

tt

s····*·,··*···*

re·*r···re·a···b

2 3

.

round

*

*

*.

'ha.

f

'C

P~

i56

i t i.i..

.t.

·

·

·

·

·,r·d·····,·*,

e90

·*8*··*·86·

RTTTT

r ment

Exe

,..

Re

.ulS

-

·

·

·

·

,····r·········

·

*····r··+··O··r,

)

0nO

n~ , g

B

,::,

D:

.0

.

yr

3......w

C, cb

Dyna-ii

3.2!

3 -

qi

o,::

> )tir

.

@

t.j

Ir

..

.

bt.

. .·

.··,r···r,······

.

·

'

,

-

t'

-ssbity .....

^,>R

e uit s ...............

,

osIA

R

Discussion

-.,L

.l

i

·

·

·

·

'2

,,·e·,···r

*········,···

·

L

·

·

·

·

·

·CI·rJ···rc

· ·

.............

r

·

,

·

inert:. iam

effec s

·

·

+ ·

-J

, *

· ··

* ·

,

·

o ,

·

36

"~_.:

k

34

····r·*··*r

Df''

·

·

,a

*····r*r·rr·,···

. n,

·

.30

'tabiility

.

ti

p.3? Combi'ned =fgc.

····*··,·r···

·

b*·*·····*··*··

·

·

·

34

,··a,,·+r+·r··

.....

e*r·····rl·r····

s..

·

·

·

+··········*···

.3-3 Downsitream

e fec s-,

APPENDIX

·

,s*r·rr·*r··r··r·r*

3.31 Simrli fid model- ..

B- Inertia

... ...

·

·

*,··***·····

.

A.JOJO~OO~l~O~Oo~OOO~O·oOOOOOJ600dOO~JOO0

..i acoa' ? . .us . nd cro c

xevri ment

T-..

t us

edur

e.

39

o

li-I

- ,

-.-Ie o , - 0rcr.

i

J. A L, " -

,-Vi

'L

~/~.oL

~

l

ort I ueJ .

.1

. -i &-)

s

b3

.. e

··

·

·

or ob

?o e du r,

· .·

·.

,

o

·

·

· o

e

®

®

i

®

·

*

·

·

®

4, *

·

t

r

and F v.

inn

h k ng

Prc-e u re, f,or

.

b 1i Aty

c:

B

APEND.X

~lrrneaia. tion

. ...tecniq~ ~°

s of . iin&.. ...

B- Dynan

_- ,:2~t.bi t y rndRouth

44

·

'

47

V~i-

L...

i:!

I- %

P-4 Noni near.,3 or umer

ogrlr r... .

A?\ NDIX 2

Extension

.:

.

r.

of Analiyis .

.

56

,81-

Inertia

1

astream

res triction.

model with

·.-2_t Comined e.feet- s models ...

PAfPENDIXD:

-:PTPENDI:X R

Re

? e 'ence s . . ......

..

.,~

--nd constants .....

Flow coeffic ients

~ ~-e

·

~

1

·

·

·

·

b.

.............

~

e

·

®

l

l·

64

L.1

Part I

1 .10

Introductiorn,Conclusions and Recommendations

Introduction

A)

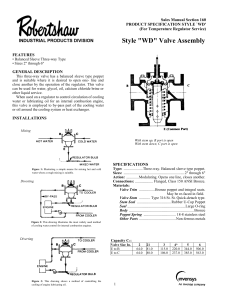

Desc riton

A opet

s a seating type valve

valve

where

valve member, poppet, has

a relative motion

to its seat.

of a poppet

Figure i-I.

A schematic

the

erDendicular

valve is

hown in

The design principle is simple in that

the fluid forces on the poppet are balanced by an

externally applied orce, usually a spring force, and

fluid

s allowed to escaoe.

This type of device has extended use in high erformance hydraulic systems as regulators,

relief

valves or

hydraulic amplii.f'iers.

Major advantages with the poppet type valve is

of manufacture,

.eakage and insensitivity to dirt.

low

The major problems

iitsease

arise in dynamic

stability.

The valve

member itself is basically a mass spring system with little

or no external damping and therefore oscillatory.

Any

additional flui.d forces in hase with the valve velocity

will lead to rapid

Cscillations

unstable

o

th s

oscillations.

ype not only degrades the vaive

performance, but when sustained will1destroy the valve.

The purpose

the cause of hi

of this

investigation

Instability

oceration wrhere they exist.

and sow

s to determine

lits

of stable

0.

J

;f

QL

Q

II

II

I

_0

I

I

I

I

I

I

I

I

I

I

I

I

I

Poppet

valve.

I

I

I

I

I

I

I

_

_

_

F

Q,- Supply flow

Qz- Load flow

Q - Relief or poppet flow

FP- System

pressure

POPPET

I

VALVE.

I

FIGURE 1-1

II

Qo

.Ba

..

g-...ound

Previous Lnvestg' tion on stabil

valves h- s been done

n sl.ding

spston

ty of ydra ul

: nd

ype vai ve .

Lee

nd 3lackburn

(Reference

)

nave shown that

transient valve forces

my cause nstabilitty.

by Stone

of poppet valves was investigated

ot.abilLty

(Ref.#2)

Static

and dynamic studies

on

neum ic fla-rpertype

valves have been c:rried out. (Ref.,3,4

nd 5)

In-

vestigations by Ainsworth (Ref.#t6)pointed out that the

fluid delivery line interacts with a valve to cause instability,

by

n investigation extended to the pop)et valve

unk (Ref..#7).

The result here is that the critical

he

system

iS the fi st;

hnrmonic

frequency

of the delivery

n

line

higher th,'nthe natural frequency of the valve.

in interestlng

shows

derivation by Frendenreich (Ref./#8)

that a spring loaded relief valve regulating a

consta nt flow is stabilizzed by the transient

orces

created due to the change in volume by the poppet motion,

but will

become

nstabLe

due to elaisticity of the'oil.

In this invest-i ation the stabil ty of the

itself will studied, rather than

srtabilitydue to inter-

:.ctionwith other elements of . system as

ixE.

.I-

br~

r·ls~ -

~,

f`~~fe~ne

vlve

this

is one steo

-,-

furtlse

:rremoved.

Assumptions will

been made as to the

e:onfigurat" on to be studied,

lnd

catin

made

articular

and an ana 1 -is will be

he sstem chracterrisstics and stability

epending on the pnhysiai characteristics.

The model to be studied will

of fluid

nertia

include the effects

nd compared with

and compressibii.itT

experimental resuits.

The analysis is

resented in Part II and the

experimental results in Part III of this thesis.

1 .20

Conclusion

This invest^gation has lead to

better understanding

of the basic problem of poppet valve stabiilty.

The major fluid

orces acting on the poppet valve

are due to the fluid pressure.

These pressure forces

have components n the drection

of the velocity and

may stabilize

or unstabilize

the valve.

shownthat the fluid eiastcity

It has been

contributes an unstabilizing

force in the direction of the valve velocity and acts as

a negative damping, where as the inertia forces associated

with fluid acceleration have stabilizing components opposing

the valve velocity

and hence acts as

The effect of fluid

ositve

e lasticity was by

damping.

ar the largest

-4-

f actor Ln theh cause

of Lnstability.

The stabilizing

component due to inertia

decre.sed due to frictional

The system

nalysis

nonlinear differential

Ls also

losses in the fluid flow.

was made by linearizin

uations

the

predictions

:nd

were

m,-dewith r-espect to system performance.

limit for stable valve operation was derived

A

and the experimental results verified the validity of

the euat ions.

This study was only concerned with the condition

upstream of the valve,

but extension of the analysis

to include the downstream effects are possible.

. 30

Re commendat ions

Based on this investigation the following recommendations

are made.

They are categorized

in the two

groups, Experimental and Design Analysis.

A.

Experimental

Further data could be needed to extend the theory

to some of the models

not considered

A more important study cn

here.

be made on the stability

due to the downstream fluid momentum effects.

re;ted

-round

o the

;the

Studies

ressure distribution and flow p-attern

ocpetwhen confined in a narrow downstream

chamber will

be imortant,

and qualitative information

is lacking

B.

Design nalysis

The nonllnear equations

that describe this system

can easily be studied on a analog computer.

on

A sudy

he nonlinear characteristics could give more accurate

information on valve stability, esnecially in the region

of small valve openings or large disturbances.

A computer aided design would also reveal information

not now available to the designer in the form of graphs

and diagrams relating system stability and valve performance as function of the physical parameters.

Part II.

2.00

Analysis

introduction

The main task of this analysis is to conceive a

meaningful mathematical model and define the p-oblem.

By

breaking the system down into basic components and investigating each,

it is hoped to gain insight to the nature

of the

stability.

The basic components are then combined and the overall

system stability studied.

2.10

Model and System Description

A- general schematic of the system is shown on FFigure

2-a .

It s comrised

of a constantustream pressure

-3 -

Ps, an

u st,rea

restr iton

Au, a deivery

Iine L, and

the system vol ume o terminated by the poppet valve.

The

poppet va ve s desc.ibed by the motion x and ts correspond-

The downstreamconditions are assumed

ing valve area 'v.

constant

and

The fluid

(3

n the analyss

PR is ~rbitrarily

s characterized by its density

(psi).

of this nature

A system

set to zero.

and elasticity

can be looked upon

as distributed or lumped parameter system.

The analysis

model a

ere will based on tlhe lumed

arameter

this will yield the most information.

The borderline

between

the two cases is aoroached

when wave transmission due to valve motion becomes

important.

The time T for a wave to travel

the distan ce

L is given by

T L;

and the particular

given as t.

(1)

tme constant for the systemrrmay be

Our criteria then becomes

7< t

(2)

and for a line -it will be shown later that t

so that we have

(3)

F?

A iS th-

weere

L.izne

ree

assume ere that Q.suat on (3) is vail d.

ment.- (Re f.9)

experi

f luid f'orac

on the

sure forces.

estbl

DwJas

ised

We

From earlier

major

the

th1at

oppet were contributed

by the pres-

t sk Lhenbecomes to caicuiate

The first

these presure

forces, and to make the ainalysis easier

models

two basic

it

1

flow.

.mean

are

first

considered,

nd shown on

2-1 b and c.

Figure

Compressible Model

Inertial effects

are assumed negligible and the

by tneorifice Au, the poppet valve Av s

system is described

system volume 2to and the fluid

Inertia

nd

and

Model

The volume

incom-ressible.

orifice,

ropperties /f

valve

%ois

assumed small and the fluid is

System is described by the line L,

nd the luid density p

The total system is then described by these combinations

in a combined model later, which will be the representation

of the system as shown on Figure

Before the actual

c-irried

out,

stability

2-1.

nalysis on -he secific

generai description of

will be cons idered.

models

the forces

nd

are

-

i,

L

I-'

General System Schematic.

(A)

-

Ps

Compressibility

(B)

Model

Inertia Model

(C)

SYSTEM

---

--

DESCRIPTION

Fig. 2-1

.

-

i,,,,

2.20 Static C,,.c

a

ers tieCs and Stbility

Evaiuation of the tatic

forceis done by a)pplyng

the momenturnm

equation to the control

Figre

(-

v oume

shown on

,-f

o

F

(ZVZsJ

eZrJ

Relating the velocitles

use ontinuity

to the

(4)

--

.;agnation pressure and

equation for the control] volume gives:

6= ---

(6)

where the dimensionless valve displacement is defined

only between

o

S

/

-

Two variations of equation (¶) exist,: ifP

he system

(7)

employs an upstream.:rflce or not.

Without an upstream orfice, Po =

faced

P

and for a flat

oDDoet CaO)

F- p . (/-b'9

(s)

The satic force is seen o ncrease with displacement, so

the oppet must be restrained by an external spring of rate

K.

,4

xp

Pv

0

0

I

I

I

'

I

r

T5

V

-

sI-

-

-

V2 P

I c-

I

0(_ L - _l

_

I

h x sin

*.r

SYSTEM CONTROL VOLUME

FIGURE - 2-2

0

K (2a7')8

(9)

to nsure st<atic stabil

ty.

For

he

case wne!--; the system have an upstream

orf ice of area Av the flowcontinuity gives

Fa

_

I

(10)

(Io)

.P__=

L

1

where

Substituted

into(5) for aflat faced poppet this gives

F

I

Fwhere

thessumpon

is made

t

hat

and

where he assumption is made -that

Cd yS23 and

Fo = Ps.,A This result

is plotted

on Fignare 2-2.

and since the force now decreases with displacement the

system

is statically

stable and with a hydraulic spring

rate

Ks=

-'2E7OD)p5 +

.-

Figure 2-3 :iso shows

vari.tion

in

(13)

he response to a slow sinusoidal

the v ve displacement.

Z)

)

cJ

c

Csj

>0

0

>0

0)

V%-

-Q

vftft;

c)

LC)

OaJ

Q.

...

FIGURE

2-3

-lThe response

s seen to deuend not only on the

operating displacement x

but also on the amplitude

Large amplitude represented by curve

of the valve.

(I) is seen to

ve

noninear

(2) gives a linear operation.

output

where as curve

Operation at small valve

neutral position wil alsogive nonlinear operation

regardless of amplitude.

This analysis is most concerned with the linear

operation because by linearizing the differential

equations analytic solutions may be obtained, where as

graphical or comuter

the nonlinear

2.30

techniques must be employed in

case.

Dynamic Stability

In this

stability

section

a general

will be given.

presentationof system

The system is assumed statically

stable and the major consideration is given to linear

operat ion.

2.31

Forces on the Popepet

The momentum equation used on the control volume in

Figure 2-2 for the dynamic case yields:

(Ae PZ)4 - F (m

ev

-ptq

VPZAVCO3OC

(14)

-11-

Eiuation (14) as wrirtten assumes that Pr is

everherp

hre

boundary

downstream

and fluid is carried

only by the fluid jet.

complexity

of the downstream

and vorticitj

constant

across

This leaves

the

out the

"low patternwere turbulence

in generalcomplicates

t e

.icture.

Considering a flat poppet only and assuming that VlcA

V2

the momentum equation leaves only pressure force and

external force to balance the momentum change within

the control volume.

evaluated,

The poppet momentum is easily

but the momentum

of the oil is more complicated.

The assumption is made that this is small as previous

experiments indicates this.

analysis).

1/9 for

(See Ref.

detailed

The momentum equation then reduces to the

simple form if P2 is

constant and arbitrarily setto

zero, and pressure immediately upstream of the valve is P

PA - F MX

(1)

M is the Doppet mass and F the external

force.

This then shows that the major fluid force is the

pressure

force actinrg on the poppet.

The pressure

P

can be derived analytically or determined experimentally as

functions of system parameters.

here

o

Both methods are employed

- i 2.-4

ra1

e:ne

_

Ti

e

orc

dration

on dsi

y

on te

(15)whirh w2rliten

pop3 t Ls described

for

by equation

system shown on Figure

n

... i,

yiedas

F- KX--

P

In

(15

)

I" nearized form where the motion x is

some oint

iven abott

xo we have

x

x0

o

AX

F = F+ AF

that

P S Po+ A P

where it

Fo= 7o

.

(z:). - X-,-This equation is shown

for a free vibration

Let us look

(F

is specified

'his

Tives

M,- C'- o

(17)

n the vector diagram on Figure 2-4

0).

at the physics of the system first.

With the fluid incompressible and inertia effects neglected

the fluid pressure behind the -poppet P is given by the

instantaneous position of tihe oppet.

Forthe free vibration

this

is shown on Figure 2-4 where x vlbra.tes

the or,'-ire

var.es

about the mern -res.ure

about x and

po, given by

curve a, but opposite of the motlon x, so it acts as spring force.

'The net work done by the fluid pressure

t~he opopet is here zero, as when t he p.D-ool-et

moves

on

nward

from

I..,.

Q0

A (0-)= -G(jeo)

r

C

Nuo\\\

X sinwt

I

(AP)A-KX- CX- MX=O

I

I

.AX

I

X= X; AXsinot

AP

P= @- APsinot

lertia)

,0~

)

)mpressibility)

GENERALIZED SYSTEM RESPONSE

FIGURE. 2-4

I--~~~~-U. 9

lI"U-a"

-

B to D the me-n oressure in

D

- F the mean

gains nor loses

pressure

and .for the outward motion

s again

po.

The

oppet neither

nergy fromthis component of pressure.

Clons-iderfirst the effect of inerSia, and use the

suoer ooswit;on rinciple, as the inertia effect will

modiy the existin : Dressure.

As the valve moves outwards, the flow ncreases

and the resulting fluid acceleration further decreases the

pressure.

On the nward motion the flow decreases and

the retardation of the flow increases the pressure further.

This gives rise to the additional pressure P1 shown in

(on Figure 2-4)

maximum at c.

which

has its minimum at position A and

The total

ressure is now given by op

(shown vectoriaily as (P A)

on Figure 2-

p1

) but as p does

not clontribute any net energy to the system, we need

only consider p.'

the mean

When the oppet

moves from B - D

ressure is greater than for the outward motion

from B -

so that the net work done by the poppet is

negative.

The

pressure p

depends on the velocity and

opposes it, so it acts as a postive

damping in that the

fluid gains energy from the motion,

nd stabilizes

i.

The component in the direction of the velocity of (P A)'

on Fi ure ?-4

s then

p.

NText ens. der the effL t of

o omree"s _billt only.u

-

apacity modifies the original

again, this addedstorage

s te

press-ure shown in a .

- ....the flow exce ed s h

di ly droos w

s.tea

e

;copet moves outward trom

mn

mnd

te

motion

on the inward

?

The additional

has a minimumat c

pressure due to the compressibility

and maximum:zt A and 2, so the total

?-4)

pressurei

as (

(This 2s shown veotoT-.lly

Again we consider

seasure

the flow is

less then the mean and the oressure rises.

+ P

4-

s now

) on Figure

the work done by pp only.

poppet moves from B - D now it

sees a mean pressure

As the

less

Po and for the outward motion is !rger

work done by the fluid on the -s

than po so the net

Again the

ositive.

pressure p depends on and is in the direction of the

velocity. This is an unstable vi-bration, as once started

the fluid pumps energy into the 'system and the vibration

increase s.

If the effects of compressibility and inertia are

combined it depends on the vectorial.

sum of the three

pressure forces if the resultant is to have a component

in pase or out of phase with the velocity.

Mathematically this will be exorressed by equation (17)

combinedwith the equation for P f(x) that wi11 be

deveiooed later.

Assumethis function is of the form

of a genera] diferen;al

equation

a() -6(D)

(

Combi.rnedbwith

equation

A tF )=

(17) this

ives

/

\H< *CD *K -#46D0)

which when examined for stability

gives the frequency equation

/MD +CD+K.,, 6(D)~ x 9 0

where jA

(19)

(20)

will be substituted for D.

Assume further that the general solution for G(D) i

of the

form:

4(D) DDzco

t

RoD+(21)

,

Substituted into 2D it gives a general fourth order

vibration equation.

/,"/I

. D*'-,

(1 cR.

:C

) ++( c K.

,qz, ( ,s,)

4c'C

6A3,)

# (C 4- )jkRo

The stability of thiis equation is given by the Routh

criteria (See Appendix B-3)

and will be discussed in

detail, as the various forms of G(D) are developed.

(22)

2.40

Compressib

.41

I

ity

Dynami Euation

n

Sthisse ion

the analysis wll

be made of the

adooted model b"y considering the e lastic propertes

'he

ui.d.

of

The system under consideration s shown in

Figure (2-'a)

The system consists of an upstream orifice (Au),

the

volume

valve (AV) and assumes

VO, and poupe,

PR constant, density

e and comprssibility

Csand

(3.

9(as ()

System eqn's:

Q

%(%o)

)

L/

Qs=

RAL

02

P;

(24)

(2)

-P

(26)

As is evident, these equations are nonlinear by the

nature of the flow, so we are going to cons-ider their linearized

.orm.

We shall onsider motions

round

operat-ng oint

of

he

.orresondinr'

-pope, wi tlh

~v~e

flows and pressures

=n

p ~ ~,

The bove operations

~ ~:etc,

akes the form (Ref. Appendix B-L)

then

Os-Q= 'DP

Q's= -

(27)

3 P

(29)

where the variables

now denote changes f rom the mean,

and D is the linear differential oerator d/dt and Ko

and K are the flow sensitivity coeffic ients wth respect

the flow sensitivity with resoect to

to ressure and K

i

valve oosit on.

These equations

solved for p vs. x give

2

o

__

ar:

3(,+,)

__

I3

_

'L1~~~~~(L~~~i+~~C~~C

Jv+ i]

(30)

(

w he re

(33)

Z/3(K3 ÷ K)

Equation (3i) describes the desired pressure variation

nd as expected itis

wit:h poppet posi tion,

a simple

with a time constant 0 promortional to the voume

I.-g

and

By

inversely pro-oortional to the flulielasticity.

the vaLues for Ki,, K2 nd K3 as functions of

introducing

geometry (Ref. Appendix -1), we can further

(32) and (33)

educe equations

to:

2 770

,a=~~i~l

(34)

Xs-I1

(3

g7

)

Introduc in a system comrl iance z given by

and the 'break frequency

,. = I

nd

=

z.''

(35)

gP

YZc=Z

r, iven

I

by te

so

Z.

r

-rt

rela tions

(- N

weh~ve

I:';ar~lrrii~ti

31a

i

and the function

piotted

on Figur>e'-t;*

The minimum ooint for

i

given

1s by

which ive

mn,,= 2.60

.t

'

r

The poinh;

.7,7

( 38)

.707.

-

t;en .re-resents

the

largest value

of

tc and the minimum brea-kf'reuency.

2.4 2

t .- i

1y

v

With the system transter

we

have 'or the

HtF-'L;st

function as given by (31.)

r-,equency ecuat ion (22 )

+ C6,X

.cD+ )D +('C+C)D

,+

ssume e

()

0, and from Arpp;endix B, equal,;on

a ,

6, >o

(39)

.

B-30'

:

Au

(A)

COMPRESSIBI LITY

r

PS

L_

r

L

Jp

F

L-

--

P

QC

i

MODEL

-

F

:L/x

FO

r

P

F

QR

(B)

INERTIA

MODEL

SYSTEM MODELS

FIGURE 2-5

Dimensionless lag tnimecons

tan

ys p.ppet valve openng

10

9

8

7

6

5

4

3

2

1

0

0

1.0

FIGURE 2-6

2.0

3.0

tr K/

: n.

-

J Mr (K+ 6r)

I

6, <o

But the i:: ;t;a ,:ttenent

by euati(on

iy ive

u~nsacbl.

directior.

(4) ,

so

we ;onelude

Lge-ntroduCd

-ve.s

easoning

of' velo t,

i

ienth

and a ine of area

.D-~ramica1 Equation

he fl1ud

,qLithdenitg

p . The generaL

-

_s

r

by

shown inby

genera

erminated

nd system is

hce cons. dered

.i

F;Sffre 2--,,

i

syster !^

for e comprie ne in thei

Mecessary dampring fCor system stability

Pr

'<

t":t

also agrees with the physic.

T^s

becase t-'

'

ts the .·.nequai ity.l

contradie

_ncom-pes1ress

*ble

and

system 1s shown in

;nd sf

oonss

.Jconstant ressure suppl

and a line of" length

L and -ea

A erminated

tre us

o -oet valve. Again we consider

the

by

lniearizeu

.foorm :

Systemeqlaaions:

I-

Li,

-,ne:

*C

.--

i" A

!-,

"I?, - df,:-,nd ,..'S

P= /-D- ,Q

;

'e

Lo c

(42)

Q S= ~ X

TValve:

CSombinre

:nd soie

-P

i

z

(4'7)

or p

oo

A(pX)

whi.h can be reduced. to the

A(9

A

-

G

4)

ToLrm

(15)

L

where the guantities are defined by equatiorn (44).

Substitution or K1 Ko gives:

L/

L

ir

( y47

a

and

=/+

.

These equatons

nondimensional

The

eid

(48)

z

on Figure 2-7 and 2-8 in a

plotted

're

foirnm.

f

.en'th a=n~diLve r>ly

c.

Cuency

#

-s p-roorional

rf0onal

to the

to to le

;ine

ressure

nd

vaive

ooenring

The vaive gain is given by

Z 'rso

For a

(49)

ystem

with anL upstream orifice included, the

ca cuiations

are the same arid shown in Appendix C-l.

The vaTa1ues for the time constant are changed by the

-tatioof the ucstrem

2 . 72

Sta'bi

to downstream area.

iy

With G(D) given by equation (45) we have for

the frequency equation

exernal

(22) with am

0,, .e., no

damping.

[M

DD'

'- (r.-':

Stability

is again given by

and

Z Ke-o6

. 462ZK)2= Z

,)

+)--

x60O

.-36 and 37 and gives

/:)

which gives

(52)

____1___11_1__1_111__-.

. ....

lead timeconstant

Dimesionless

- --L-l_--anu-hnT-·

,_

-

2n

..

v

vs. poppet

valve opening

18

4

1

.20

10

6

6

4

.80

.2

0

.20

.40

.60

&

FIGURE 2-7

.80

1.00

L)

Q

V)

QL

C

I

Z)

Z)

WV)

rv)

()

V)

ci,

LI)

Q

III

(i

C)

0

0)

'L v1;)

11

C

11

C\;

04

I

F

C

C

0

1i,

11

)i

I

C

tN

C

(O

FIGURE 2-8

C

From equattion(

we see

above inequalitty

as te

the inerta

always holds.

This shows that

descr ption

ishlc given earlier and the commonent

his lead ooooses the

of force due ;o

acts

. s

system is always stable

tabl izes the .alve, whichverifes

force

.

The

that this

valve

velocLty

and

ositive damning.

CombinedEffects

2.60

The orevious two sections showed the effect of'

Vluid elasticity

.4and

inertia considered separately.

These effects can be checked experimentally

in a

laboratoratory experiment, but in a real model they

occur in combinaton.

In this section the model shown on Figure 2-la

(section 2.1) will be treated in a more general sense.

We are still

concerned with the lumped Darameter model"

only, and frictionless

flow.

Combning the effects of fluid inertia and elasticity

?-ve rise

to three basic configurations

shown in F gure

2-9*

Model a is the straight

pressibility

sfeot

Models b and

n

*i

J,J4;

1

!A

,

nat

-

r-inc:

and com-

ombined

with the pooppetvalve.

aIe two varia-tions

tm-

.e:

'

forward inertia

of a with the

introduction

_ , ro

nce

Theoe

s-wo models

lcora

u

Len (Dynam.;.i iaract rL. t cc. ;

1L

'l1kle

Combined effects models

X

13

_-

cOx

La

R

L

3

C

FIGURE 2-9

-~~~~~~~~~-_

-24

pressur

dis

slacement

differ°e The analysis

o

for

these two cases are shown in the ATppendix (C-2).

Attention will

2.65

ocussed

node

on

now be

a.

Dynamic Equat ion

The inertia

ompressiblity model nder consideration

is model a of Fi-ure

2-9.

The system consists

o

a

conotant ressure source po, with a delivery line o

length L and crossection A onnected to the volume

and the poppet valve.

The downstream condition

are steady, pR assumed constant and arbitrarily

to zero.

The luid has density

p

set

and elasticity

/

In this lumped parameter model all the volume is

(psi).

lumped into ' o and the line L considered incompressible.

From the previous analysis we exnect the system

stability

to depend on the relative

lead (EL) and lag (')

magnitude of the

time constants from the line

and volume models respecti vely.

System Equations:

A

0

(5:)

Line:

p_-[+D*

Volume:

Q,,-=hg

-DP

(54)

Va

Q =l, X l p

(55)

( / .., )

vel ·

?R -

J, K- and. K

used

revLou sly.

aive

are the

flow coeffiints

By combniing and eliminating

AP_

which

as

the VI.ow

(56)

an be

ritten

as

(R7)

where the coefficients are defined by equation (56).

introducing the values for coefficients using t

tc'

2

the equation

reduces

By

LA/r' and

to

02(59)

I'

((6c)

These last euations with equation (57) give the des.ired

functions to ook at the combined stability equations.

2 .62

Stab

ity

The desired frequency equation is obtained by

substituting

(57) into (22) andgiven

,qNoS/o3 -iYo

-lls----lpB--l---

LI_ .I--^^I___ ___._ _ _

i9634o

below

cAX=O

().

-6$ a

Her, - and K

ThmestabiALty

a frst

arro

.Xiaton.

. vena by -35 is

Beo.fo substitutng

we tan

the right hand sde

smal1 or negligible, and when 't is

large.

roups

see two

when

In order to investigate further we htave "forthe

in (62)

involved:

(63)

(X(T4,)

;'---

(_

z94P&

_

Cr

(65)

reta2ostans

BoXth and R are constantsrplaed

of the

evident; as

(6(

)4)

R

-uastream

cases here:

-

oppet.

to the cond]itions

The two oonditions

0 euation

(63)

(i6)

now become

'secomes zero, but

equation (64) tends to _infinity. Tle inequality of

(62) is hen violated, so at very small displacement8 the

valve siould fe unstable. Solving (62) gives

___I__PII__IIII_·_I·L-·-Yln-*L-t

i--

but for

tiIa

his reducs

o

(6)

ifthi=

7DT'X

6

this

becomes

Eqauat-on(693) ives the stability

limit for smal.l

valve dislaements.

For stable operation x must be greater

than the right hand side of (69).

The other two roots to thLs equation can be found by

using equation (67) for the condition R-0O and

large.

Th. s yie ds

gt

ii4

(70)

or

Xo<

2"

e:

(71 )

Equation (71) only makes sense for values of the

s(quare

oot l.es; then unity as x o larger

no t r

-D

ersent a ::so:

on (o e >

,

than D/4 does

"ter.ombn

Lin'

(71)

(657) and

we

ave.

i, o

_4(72)

eLR

Equation (72) then descr*ibes the desiredstability limit

on displacement of the poppet valve.

If the external scpring is included the stability

equation becomes:

(74)

'7For

,

ZP

momD

(75)

small, this becomes

(/+5)- }?fR~ff+)

Figure 2-10 shows

a f'unction of

Figure

o-1i0

shows

7(76)

he general trend of equation

, the nondimensional

;

tends to infinity

rate.

sring

at

(76) as

I?

when

the denominator of (76) vanishes, but of more interest wouid

,-e

when

S

given by

unity,

ntproachs

*

Y

I.I1

lI

I

I

¢

/

/

/

II'',

I

FIGURE 2-10

-29-

7-

If then

2.70

- point of stable operation exists.

Downstream Eff'ect

Downstreameffects

are connected with the possibility

of pressure variations behind the poppet due to flu.d

mot ion.

These are due o both fluid

and comD-res-

nertia

Ibility, but also are strongly affected by the luid

vorticity

and turbulant mixing from the jet as it

leaves the poppet

Previous investigators

(Stone Ref#t42)

noted that

a popet stable whenexhausting into a "infinite

?

downstream chamber would oscillate when confined by a

circul'ir tube, indicating that the change

n flow

pattern caused by downstream effects and largly due to

fluid compressibility. A simplified

analysis

will

show

the adverse effect that this may cause.

2.7i

Downstream Compressibility

A

it is

simplified system is shown in Figure 2-i1a where

assumed the upstream

do.wnnstrram

volume

is

pressure n, is constant, the

and the :restric

tion

y simil itywe know that the equation

co

_

4

_

o, Tze

it

doH

o- n t.

is

given by AR.

are those of

e 1t

(7a)

rhere

(80)

lefr4l(/Ll

K4 and K5 are the flow coefficients

with respect to

D.ressure for valve and downstream restriction.

The

dynamic equation in this case depends on the downstream

construction

In this

of the Doonpetas shown on Figue

2-11 b.

case we have

,~ i A.n ,-- -x - ,,v,X

which for linearized considerations yield, with equation

(79) substituted for :

(f z

/3 #zD 3

c )OD

For stability:

(Ref. Aopendix C)

2,

Qc0

Zji.

(744 Ito.

kZR)O Q 6 RRe

(82)

> Qs ao

(83)

>'G9

(84)

.(.(

A

(A)

SCHEMATICS

'ORCES

AR

A

_

F

meKX

c

DOW N STR IEAM

FIGURE

-

COMPRESSIBILITY

2-11

~i

I",.

Z

a.

C

-J

U)

(D

6<

II

cn

U)

U)

w

cJ

So

0

0(o

0,

0

0

00

rY)

<a

<'

C'M

0 0

0

,·

-31 -

K r&/

or hen subst t ted

(8)5)

forCR

,9 ZP77Ln9

Z

(86)

wIhere

bt=

Figure

s*R.

(87)

2-1:2. shows tie behavior o

ecuation 86,

two values o

K

stable, wile

a has the unstable region

in a and

.

nd for the

The value of "O -. s always

iven by

he

intersection of the line with the curve defined by

E:uat-ion 8b.

Part III

3. 00

Exoerimentia

Results

B'ckground

The experimental

is briefly

outii red

ionaratus and test coreedure

in Aooendix

results are divided into

The ex.perimental

hree groups, Statilc Characteristics,

Dynamic Forces, and Stability.

flow

A- .

In Appendix D are shown the

oefficents for the fixed orifi es and the poppet

valve.

Thse vaLues are used in evaluating the results,

Al th;e "

,-suits

~reented are for

'a O.

orpet of'

,d'a eter

=

gi,in

i3eh

o -il id t

i "..amter

o

rem

l'i ne ;'}Sd

the ioZ7 .] e is D)

1.0 Stat c tCha..

TMe s"tat1c

Figu res 3-I and

force

for constant

shows the fove

n- '

-1,'

Ae.

erist°s

press;

or e

and

re curves

-.

Figure 3-! reoresents

ae

shown

n

the

ipstream oressure. Figur e 3-

and utistrearm; oressure

orifice Au is ntroduced.

:txed

Lwhen

The dashed

curves

eyresent

the theory given by equation(12and Figures '-3 with the

The

sine wave.

response to a large input, slowly varying,

output is seen to be nonlinear

as expected with the

pressures less than the teory

predicts.

The discsepancies

in flow coefficients,

are largily due to the variations

especially

eak

that of the poppet valve. (Ref. Fig. D-').

Again Figure 3-2 gives indications on the (low

frequency) output to be expected as function of vaire meran

oS' tion.

.-

3.20

Dynamic Characteristics

In this section the val;dl t

developed in sections 2-40

y

of

he equations

and 2.50 were checked out.

The poppet valve 1isexcited sinusoida1.ilyand the force,

dis-lacement nd upstream pressure is

arfed t toe

teory.

recorded and com-

Ill II

I

Ill

__ I

I

i

i

-

_

I

I1

II

Ill

L

.

-4

I-i

C

E

-

I

I

ii

I

I

U

1o(0.

0

i

\II

i

ii

I

-\J

i

I

_

\

A

I

I

0

_

I

N

-

-

_

_

I

I

.

I-

I

U

0I.

Ix

I

I

I

0

Ol~

0

0

I--

--

'Q

--

I-

0

0 t

0

\--

JA

0

---- --

U

--

Q

C)

- - -

(n

_

0,n

-_

0 0 0CM

11'm

*:

' a

.

0

-

zl

V"O

0 0 0

eO

0)

o

r

a."

FIGURE 3-1

Vwo

0

c(i

n

0

0

0

0

0

L

II

0

cL

><>

.)

LLI"c6 i o

FIGURE 3-2

0t

SLnce tie

~ on~~ from 0 h

.rs'~n~

omne

y

t

i

i

erome,ry

as m

is F equ ei

enc

pce

paratus

3- trough

(ot)e at

cps)

a .n mi

u o.? of th e upstream

C )~ the ma

agnif

led to create measurale

Lag values :'or pre ss re

The results

ii; ed

,ead and

and force.

cart

from thi

are

sown

Li.nFi gtlres

3-7

a Compre s s ib I ity

1k.

Rte sul isS:

,

3.

The system tested is that shown on Figure ~P-ib.

In the exoerimenta. st-u,

both L

.nd

u

are changable

as :well as the mean valve position [o (or Xo).

Figure

3-7 shows the phase lag ~ betw-veen

either force or

pressure with dis.olacement as a function of system

volume. Figure 3-4 shows the effect

of changing both

volume and valve mean operating postion.

shows a crosspiot

Fifgue -* -

of data obtained from Figures 3-3 and

3-4 on a nondimensional

b-:as.

and i

to be ,compared with

the value of equat ion (37)

·

B.

Dis ussion

The results

oS Fi gure 3-5 follow the theory well.

The vali e used for

Pis

when it i - -onsidred

th;t

·.eii*

d

rwvaic.

u

UC

TVr

r50,00

,

OSi, WiCi

is high

the oil haesai

entrained

tl.t

.

't-e ?I> Jt

'T

C c

O

O-

j

c~J)

0u

u

u 0L

O

LO.L) O

II

U

1

C

I1

I1

1

U )

X) - CJ

0Ln

LOC

(Y)

0

QL

.......

-4il--

I'

LCJ '0cLu

.-

I

I

-

I

I

I..

-

I

I1

oO uU

-

CM

......,

0)>

LO

O (n

O

O

0) 00

O

N

O

()

O

LO

10

O

FIGURE 3-3

O

Cv)

O

NM

O

0

o

V

0t

0)' 0

LO O

O

II

tI

II

lii

II

(~

(1

'

a0.

0

51

~

i

I

II

Lf3(DaEL

<

I II

0

Ln

0

LCI

(Y)

Lc

0

0)

0

0.O uc

3

I WA H~~~~~~

1)

U))

Oo

0

t >

iiH

i

CU

Ii

c'J

(Js

b O

aUL

0

0

1

00

a)

O

0

O

N

O

CD

O

I)

o

.

0

0

(V)

C

FIGURE 3-4

FIGURE 3- 4

0 0

Ex

10

imental

time lag vs

pet disp

cacment

9

8

7

6

5

4

3

2

.1

0

0

1.0

2.0

6

FIGURE 3-5

3.0

X'0

t)

I

.5

I

I

Q(

IG,

D

1

A

!t I. I j4

-rLAuIlkLU

%

0 1

G,(j

Newtons la.

C

(iP)A-

or:

- KX = M X

-G,(j)A-- KX-CX~~~~~~i MX = 0

_

,

.

.

..

.

..

VECTOR

-G

-w

---I4~yle

unstabilizing

comp.

I

I

I

II

Le\

.

DIAGRAM

a

aT

\

_

-C

I

I

I

I

LA G

EFFECTS

FIGURE 3-6

;

-

dl

s

-

a

%

x

of" thiK

urve

is

n -sebjly o-rot>o

na

rt

i o

se n

is oios

witnhn ressur

oeffi- e;nt,

l to

s,hne

su

urroo

the

rlow

-t ,cn be een that K-

nfrinid for -ma'

starts -t

(34,}where t c

fornm equation

and de

r

ases,

whle

K,-

then gives :for the

starts at zero and. rncrease. The l3um

resultant

at

aquation

ai maximumfor t

(or minnmumf'or f,

S .707, Thraex-eri.mental va).iue here areed

Since the excitation

low, the nertia

nelLigibie

and

reQuency..

.

of t he popvoetis

force due o the

he fluid

motion

ooppet is

forces were measured directly

by the force gage. The resultwas, then,

fluid forces were those

caused by the fluid

in phase with the nressure.

this

results

that the

pressure

and thle force diagram snows the resultant

force and that itt has a

and

For the case of compressibilitv

Figure 3-6 shows a summary

is a simple 1ag.

we l.

omponent in the direction

of

the

ressure

of the

veiocity so that it is unstabilizing.

3.22

A.

Inertia

Effec-ts

Results

The

iJnertia

model tested was that given by Figure

2 5 in

he analysis, and the results are oresented in

Figures

3-7 and 3-,3.

variation

Figure 3-7 shows uantitatively the

of the ohase ilcad of' ressure and force against

valve

displacement

the data

and

presssure.

obtained for variation of

F igure 3-

contaii

al1

he oarameter, eroT0S

Jotted on a nondimensional form.

3. Discussion

The agreement between the theory and model was

initially off by 20, at the most, but by including

frictional losses and entrance loss due to the constriction

ait

both the valve and source and, the theory and

exoeriments agree well.

The experiment shows that the inertia

force gives

riseto a phase lead. and that this is realized resist in

short

lines.

Figure 2-9 shows a summary of

with the transfer function

()

he system

substituted into the

dynamical equation and this shows that the nertia force

has ~ component proportional

to the velocity,

but opposing

it and thereby acts as positive daming, hence stabilizing

the valve.

The effect

of friction

as a restriction

can be lumped and considered

(Ref. Appendix C-i) and reduces the time

lag predicted.

3.30

Stability

Stabilizing

t'orce Fo

L~~~

= pA

the poopet was done by applying a constant

:and havin g the

_____

^____IW__L_^__iX___YIWLP___I____I__I

pet

suspended by

Pt~usoece

____

L-_·II·I··I)LII--l-·-----Y--_l

--IICIIICCIIPPlp CIIP--·-- --

0

ea.

O

0

O

0"

0

0

. J

0)

o

I!

11

0

I

I

xO

0

0Ln

l'

I

0

'Co

N

ra~t 31

I

0

0 >

ol

cn

L.cC

Ln

a.

I

CM

'IS

0 >

lI)

N

0

0

4

0 .

a.

I

----

I

-

I

I

I

0

FIGURE 3-7

I

0

I

0

Line lead time constant

vs. poppet valve position

15

14

12

10

8

'V6.

4

2

0

0

.20

.40

.60

A

FIGURE 3-8

.80

1.0

t

I

i

I

QS

Ps

I"&l

I

i

I

i

I

I

(X)GtD+

i

().t

- L-7rt1

i

1

Newton.

or

(AP)A-CX -KX-MX

-G(jc)A-KX-CX-MX

VEC TOR

=0

DIAG RAM.

II

+X

- bI +X

ig comp.

LEAD EFFECTS

FIGURE 3-9

The system damping is practicail.

pring.

cantileverecd

zero when ter

The mean

:iS0o ydraull

of

sition

o

the

ressure a pl ed.

I

oopet was stepwise

cha;nged and at each position it was plauced.

the 2nsu n

died ou,l it was considered

vibr.tion

This metnod, even though

stable.

f

rude, has a fair

degree of accuracy.

Simli fied Models

3.31

A.

Compressible Model This model was always found

unstable

The :freaueny o oscillation

as expected.

was given by the combination of the hydraulic and

popet mass.

applied spring rates and othe

B.

Model- This was

Inertia

ound stable,

small displ-icement, it was unstable.

but for

The reason

here is that at small (displacements,t he volume

intertaction of the line becomes important

nd the

system approaches that of the combined effects

re-

-orted next.

3?

Combined ffe ts

The stab)1iitJy

teaistic

system

na ysed

n section

of what may be

Twas

tested here.

:.cO,

onsidered

a more

The system is that

and shown on Figure

-9a.

Ih

these test~s the Lne

were varied

w

,i:~D-uy

~:ressure

The results

dip3lacement.

1.

thro

o.L. ures

~rn

r

t

tr

are sown

on

igure > 1 -renrp

Ag

3-10 and

e vve

n Flgures -10

t2

eauations (5)

limit

and (69).

t

he experiment only cecked

0. The

had no meaning here as the square root 'I

equation (70) was always

was

ross

l.

,Jhestaibiityfor the lower limit, I..

upper

i

are here ,comcared

again to the theory

The results

for

7, volue Ir and te

.nih

then stable

larger

than unity.

The system

for values larger than the exnerimental

curves.

Within experimental error the experiment agreed

well

with the theory, and it showed that the euations

definitey

h?

ad validity.

Two main factors contributed

to the difference in the e,,erimental

theory; the value for

and f'rictional

effects

results with the

of 250,000 psi is too high

decrease

and raisethe stability

t e ffect of the ead

limit, as ndicated by the

previous experiments.

3. 30

Downstrea-m

Ef ec s,

A qualified analysis

'ring

e

of this was

rim l...lv stiaLot

ot made, but

,1lat

i ns

..-

L

a

()

u 0 '0

LO

) 0

,

(n

U)

In

U)

U

C

L-

i

>'

0~~~~.

:

x

u3,

(U

I

I

l

I

o x

r-

I

0x

0

o

z

w

CL

U

w

a2,

LJ

V)

C

0

00

C4

0

o

0

0

0

0

0

0

0

0

0

0

nssad cddnS

!sd

sd aJnssJd: lddnS

FIGURE 3-10

0

x

-

m

w

-)

>00

i-

Ub-

Q ~~~~~~~~~~~~~~~~~~~~~~

C-

ft~~~~~

54~$0

QI )

:IQ) z

03

Q

II

II

s~~

-i~~~~~~~~~I

v)

0

0

oQ)

0

t cz

CO\

0%

CO

t%%Z

·

Lrj

N

%

crP

90~~~~~~~~~~~~~~~~~

.

a

I

_

z

0

L

n00

0

(n

i.-

a.

n

U

U)

C

u

>

0O

C

0

to

·n

L)

H.

>

a

E

II

A

XI'

0

11

0O

II

I

I

X

<1

.

I

i

CM

CQ

oD

(D x

-J

x

CM

FIGURE 3-12

occurred

that

er not expl.ained

:Rot no external

the

sorin a

opDet woulld

osc'llltions

by

ied

he theory.

or very

into

no siow os.c liat-ons

occur ed for

w

These same

valve

Irferdisplacements or

Kr e fows when "he valve was restrained by a hevier

Th is seems to tie

comoressbi

;he return

fre'quency o

the valve.

in

with the

effect

downstream

i ty as out linedin section2.20.

line

was

oscil

tA-ted with a gate vve,

ations

Since

the

could be changed by cosing

The downstreampip Ing consisted of elastic

hoses which reduced the effective

system.

of

spring.

compressibitLity of the

A I•ENDIX

A:

Exper:mental

arparattus

a,d

,,ocedure

The Ao'

aratu.,

An -acarat.i was des i.ned a-nd esed

Murra.y (Re.9)

as

art of a iMaste

:

by Taft

Thesis pro ct.

This same ap.-aratus was sed in this investigtion

with somemodifications.

The schematic of the apparatus

s shown in Figure

A-I.

The apparatus consists of three major nits:

the nozzle, the poppet and he drive assemblies.

The nozzle is a removable unit and can be

changed to conform to any pstreamn condition that

one would like to represent.

The poppet assembly includes the poonet and the

drive stem.

The stem s housed in an air bearing to

reduce friction

to a minimum.

A ,compensating chamber is provided, applying

constant force by the Air pressure p, to compensate

for the static

hydraulic forces on the popoet.

force gage s an integral

part of the stem.

a semiconductor bridge-type

The

This

gage with very high stiffness

and sen-sivty.

A iLnear, variabie,

s

differential

transformer

(L.v.D.T.osltion cickup is attached to the stem,

I

Lt

-

LL

0

U

I

:

w

,*

v

,q

LL

to mornitor

va.

e d

is_1

acement .

The drive unit is a sinusoidel. am, provided by

grrnding the cam surface that holds the cam bearing ecentrl

Ito

the two mairnbearngs.

The

can

am displacement

b varied by movin the cam bearing in any position

between the bearings marked () and (2) and is roportional

to the distance rom bearing

(i). Range of eccentricity

s .001"

s.eed,

to

The cam is driven by a variable

O07".

motor with seed range from 3.0 to 45

electric

cycles per second.

The upstream pressure

s measured by a pressure

transducer, mounted in the nozzle housing immediatel.

upstream of the nozze.

The electron:.c instrumentation

pensating

networks,

preamplifiers

consists of

and a C.E.O recorder,

The output signal from each transducer

s preamplified,

then sent through variable gain and damping

network to be recorded on the ballistic

This gives three simultaneous

and displacement,

om-

compensator

CEC Recorder.

traces of force,

ressure

and the phase and am litude relation

can be deduced easily.

Calibrat ion

The calibrat.ion

Tke uorsss

re

was -erformed a follows.

ensi;v

ty of the pressure

t:ransdu cir

was cmheked aa

g

ns t

innutt to tthe iie,

gTal'vanome ter

ea

e

-t

ii

of

of'

5Ihs.

At 2

VDT transducer

.indicator to yield

a

ive

by arnlyi.ng

vO

iltS

was checked

senstivit

o

a

exc - tation,

outout wa adjusted to give def-lecton of

The

a 6 voit

i/In

OK

The forc. gag- was cai Lbrated

known foru

o

et so 3ao

and the gain

defecton

este

it.

'bs/in.

l

agains

ta

aiial

.0 02T'/n of

ga vanomete r t raveit.

These ca!ibrations

were done aFteach set of runs

s the

output of all these transducers

proportional to

.s

the excitation voltage.

Procedure for Obtaining

P and F vs x.

The rocedure here was straight-

apar

The

,.tus

had rovisions for changrlng th,e ustream

parameters

L,?To and the vaive dislacernent.

uostream orifices were fxed,

was

The

but ,2'hangabie.

For a given set of conditions

st an

orward.l

the hydraAulic test

tart-ed alon g with the varUi ble see-d : oi;or.

Data was recorded at s-peed increments both for increasing

-'nd derreasnag

speeds,

and dwelling

eacn speed to assure "steady'

ol:ong

(uni f orm)

enough

;t

onditions.

-

ProtCllur.for 'Cv: licin

o-'the oope

et

one of

' e

en -et

the efnd'

.o of th

sautort.

eraing

the

-tenm

and

catn b

of lengtli to thicklnes'

The dynamic resoonse o

on

-

srg;l- .E

The sp" ng r ate

va-r:ied y changing the ratio

was checked out

, "

w

valve,

seru.-3oi ded da vi was removed and a o,.mflvered

wasttached

,

Stability

the st;ibLty

To t.est

q C-.

4.

the ocpet and o7

ot.thae

3rng

the oppet dis l--picemrent disr i-'red

nd

-ioso - oe.

n osc

3B:pluclking the .oppet, the natural

rrequency and

damping could be de terrmined.

The damning ratio of the system Twth no hydrau c

pressure

on was from .03-.05,

:n the theory that c

so the assumption made

0 is good.

The natural

frequency

compared we11 with that calculated.

To determine the stability

for any given ustrea m

configuration, a constant force Fo was applied

pop.petto

ompensate

force by the

The poppe

for te

onstant air

the

steady-state hydraulic

ressure

position was then changed through out

the range of interest each time it was

ing a sep :input),

out, the

to

and if the

luc ked (represent-

nitial oscillation

ystem was stable; otherwise

died

t was deemed

-

urst. abe.

Att tmes I ticas not ev

neessaru to touch

the oeu

-tocheck Its stabii ty.

Eventhough ths

method seems :riude, wth a bit of

s onsisttfent resut .

yild

PE

or iX,

..

t

D-

44F

A P PEND I'X

B- i

Linearizat-ion Techni-iues

Or fl3e

and Valve

low Equations

Consider the flow through a variable

in an incomoress ibe low.

The flow rate

orifice

(n3/se

)

is then given by

whe re :

c -

orifice flow coefficient

orifice area (in 2)

Av = C0 X

5

fluid density

Pi and P2 are the upstream

nd downstream fluid

pressures in (psi)

The linearized form of equation B-i is arrived .t by

considering the small changes in flow around some

ing point given by the valve displacement x.

Sincr flow is a function of both nressure ':-ndarea we

operat

write the change n flow as

0

=/r,Ax

-X'-IZ2 AP(

(B-

)

where K and K are constants.

eva' uated

s

These constants

, A i is oP

Mathematri

o lOwS.

is

the f orm

and the total

change in flow given by

By comparison with B-2 this gives:

aX1)

k,

(B-5)

~xyx

where K, and Kr) are evaluated at the oerating

An example of this technique will be given.

poin.

Consider

the flow from a constant pressure source through fixed

orifice A

and a valve (Ref. Figure 2-i) where the

constant pressure is Ps, the intermediate pressure is

p

and the exhaust pressure is arbitrarily set to zero.

From the continuity equations we get for the

ntermediate

Dressure

J

P

Rs-

1

(T

7'

.r.

F" ow or

2nIed

it....

o<e

otroena

from

the

a6~cA- /4t31Ž

F om - weobt1-in,ay

(B-9)

If-erenti atlon,

2_)

2PS P)

2/P

(B-iai )

-7 gives:

but the use of

gqain"

b

Eoationm

tMd

53-1 now de scrlbe

3-a

Fixedor lI4

.....

ifny oeer

c:;

t

1

ng

>

jAv

-1

73-2,

I-voc

Iee

downst

= r/ X

t.¢ n t

The

t

e.'i

l:iow through

valve

the

kztp

f-1t`LQ

o, J

th-

of the valve.

point

.tlAdx

P:o:rt e

ts5 i

)

fow

is:

(s- )

. iv

S.'

res

, -3-I -I- - ,- j,II

I

i

...

:1.nd

:::i wiit

s

Dynicm csiz

f

-i

_Lin

:

frictionlesu,

The dynramic-- equtcior of Incomnressibe,

0ow f or

i

section of p ,:

ip

e

,a differenti

.,.re sp

differ

.~ eanh

i3y

:p0

shown r Figu -e

:i s

1 Lien

-ced t

PA-(p dp)()

part

-a

Asecion

The two sections

ind thre propertie

'

mon ts,

T4d

4dR

d ffe:renti. tl equa tion of mnoton for

sthe

(B-.'6

line

e cro

i

2see s t on.

olf v7.';r

'ab

For

(x

r yieids

torde

d(p4)=pwqdfdX I

This

i

-i

of mot:Lo- we have.

l -Js of higher

D±

ro'ing different

-1ia.

ornly by diffeent

.ewton's equatilon

lying

Coonsder

d e re.

ot o

ne Wi 1 be de vre

I

T-Q -e°omes,

l-

e, of , onstil,nt

n

n

t

ir'e ;

ed

nd en th L,

e1u-on

I---

dx --

I

I

I

I

I

I

I

p

p+dp

V

V dV

A

A+ dA

Valve

L

H-

L

Valve

I

©

DYNAMICS OF A

FIGURE

B-1

LINE

/

.....

"n+u

tn

O

J"

.(

Sj

I}i iIr)°-)S

4.

.....

j

.

I:

ra~r>

v

e2

>A

of

3

-rt_,.a

cornz

Th-b

in

Fe rs

2onrected

o° the vae

('

F1o-*

3n

2,

=

from the

nta

-uA

(

'

'

i n,

hownna o

o

to the oine

:eeY the relation

the

1

,d:,'l1,.s, :ow