Read – Prudent Practices Chapter 9 – Governmental Regulations of Laboratories Read Paper 9: “How Can I Prevent Laboratory Accidents?” by Kathy Benedict Summary 11 – Government Regulations and Laboratories

advertisement

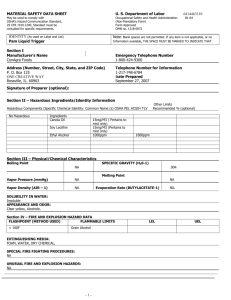

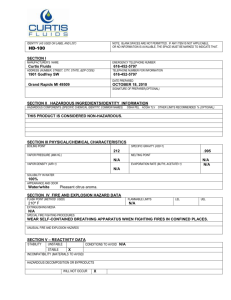

Summary 11 – Government Regulations and Laboratories Read – Prudent Practices Chapter 9 – Governmental Regulations of Laboratories Read Paper 9: “How Can I Prevent Laboratory Accidents?” by Kathy Benedict The most important laws and regulations that affect laboratories are the Occupational Safety and Health Administration's regulation, Occupational Exposure to Hazardous Chemicals in Laboratories (the OSHA Laboratory Standard) and the Resource Conservation and Recovery Act (RCRA), under which the Environmental Protection Agency (EPA) regulates hazardous waste. The Clean Air Act and Federal Water Pollution Control Act protect public health and the environment. The earliest OSHA standards were designed for exposure in industrial not academic settings. OSHA in 1981 undertook the development of a special regulatory regime for laboratories. The Laboratory Standard, promulgated in 1990, was the result (see Appendix A). In its Laboratory Standard, OSHA refers to the National Research Council's (1981) Prudent Practices for Handling Hazardous Chemicals in Laboratories as "nonmandatory ... guidance to assist employers in the development of the Chemical Hygiene Plan." It is anticipated that the present edition, Prudent Practices in the Laboratory: Handling and Disposal of Chemicals, will likewise be referenced. The Chemical Hygiene Plan The centerpiece of the Laboratory Standard is the Chemical Hygiene Plan. This is a written plan developed by the employer (e.g., university or research organization) and has the following major elements: · · · · · · · · · information and training for employees about the hazards of chemicals in the work area, including how to detect their presence or release, work practices, the use of protective equipment, and emergency response procedures; the circumstances under which a particular laboratory operation requires prior approval from the employer; standard operating procedures for work with hazardous chemicals; criteria for use of control measures, such as engineering controls or personal protection equipment; measures to ensure proper operation of fume hoods and other protective equipment; provisions for additional employee protection for work with "select carcinogens" (as defined in the Laboratory Standard) and for reproductive toxins or substances that have a high degree of acute toxicity; provisions for medical consultations and examinations for employees; and designation of a chemical hygiene officer. PELs and TLVs OSHA standards establish permissible exposure limits (PELs). The Laboratory Standard's provisions require exposure monitoring and medical surveillance. The 1 requirements for exposure monitoring and medical surveillance are found in Appendix A, sections (d) and (g) of the Laboratory Standard. Threshold limit values (TLVs), are found in a nonregulatory consensus document prepared by the American Conference of Governmental Industrial Hygienists (ACGIH). “Threshold Limit Values (TLVs) refer to airborne concentrations of substances and represent conditions under which it is believed that nearly all workers may be repeatedly exposed day after day without adverse health affects." TLVs are average concentrations over a normal 8­hour work day and a 40­hour work week. The "time­weighted average (TWA) exposure" indicates that exposures may be somewhat higher or lower than the average at various times of the day, which is typical of work with chemicals. ACGIH also recommends, for some compounds, a short­ term exposure limit (STEL), which establishes a safe exposure limit of no more than four 15­minute periods a day. STELs are published only for compounds where toxic effects have been reported from high short­term exposures in either humans or animals. A "C" preceding the numerical TLV designation indicates that the TLV is a ceiling level concentration that should not be exceeded during any part of the working exposure. Particularly Hazardous Substances The term “Particularly Hazardous Substances” includes: Select carcinogens – (1) regulated by OSHA as a carcinogen, (2) listed as "known to be a carcinogen" in the Annual Report on Carcinogens published by the National Toxicology Program (NTP), (3) listed under Group 1 ("carcinogenic to humans") by the International Agency for Research on Cancer (IARC) Monographs, or (4) in certain cases, listed in either Group 2A or 2B by IARC or under the category "reasonably anticipated to be carcinogens" by NTP. A category (4) substance is considered a select carcinogen only if it causes statistically significant tumor incidence in experimental animals in accordance with any of the following criteria: (1) after inhalation exposure of 6 to 7 hours per day, 5 days per week, for a significant portion of a lifetime to dosages of less than 10 mg/ m 3 ; (2) after repeated skin application of less than 300 mg/kg of body weight per week; or (3) after oral dosages of less than 50 mg/kg of body weight per day. Reproductive toxins ­ chemicals that affect reproductive capabilities, including chromosomal damage (mutations) and effects on fetuses (teratogenesis). There is very little agreement on how to determine "reproductive toxins." Substances with a high degree of acute toxicity ­ not specified further, which has made it difficult to apply these categories. Some institutions have chosen to adopt the OSHA Hazard Communication Standard definition of "highly toxic" (LD50 < 50 mg/kg oral dose) as a workable definition of "high degree of acute toxicity." Protection of Other Personnel in Laboratories OSHA standards apply only to "employees" of laboratory facilities, which means students are not covered, although custodial and maintenance staff are. The OSHA Hazard Communication Standard, specifies the information, training, and health and 2 safety protections required for these employees. Colleges provide protection of students for moral and legal reasons. Federal versus State Regulations ­ individual states may be authorized by federal OSHA to administer the act if they adopt a plan for development and enforcement of standards that is "at least as effective as the Federal standards." A given institution may be subject to (1) the federal Laboratory Standard, enforced by federal OSHA, (2) a state Laboratory Standard, enforced by state OSHA, or (3) if a public institution is not subject to OSHA regulation, state public institution health and safety regulations enforced by a state agency. The environmental health and safety office at each institution should have a copy of the applicable standard. The Hazard Communication Standard The Hazard Communication Standard, on the other hand, applies to all nonlaboratory operations "where chemicals are either used, distributed or are produced for use or distribution." The requirements of the Hazard Communication Standard are, in certain respects, more demanding than those of the Laboratory Standard. For example, the Hazard Communication Standard requires that each container of hazardous chemicals used by the employee be labeled clearly with the identity of the chemical and appropriate hazard warnings and that copies of Material Safety Data Sheets (MSDSs) for each hazardous chemical be readily accessible to employees. Definition of a Hazardous Waste Generator Under RCRA, a generator is "any person, by site [emphasis added], whose act or process produces hazardous waste .. ." (1) Large­quantity generators ­ 1,000 kg or more per month (about five 55­gallon drums of hazardous waste) or over 1 kg of "acutely hazardous waste" per month. By this measure, most large research institutions, including the larger universities, are large­ quantity generators. (2) Small­quantity generators, to whom special rules apply, generate more than 100 but less than 1,000 kg of hazardous waste per month (and accumulate less than 6,000 kg at any one time) and less than 1 kg of "acutely hazardous waste" per month (and accumulate less than 1 kg at any one time). (3) A conditionally exempt small­quantity generator generates 100 kg or less of hazardous waste per month and less than 1 kg of "acutely hazardous waste." The special requirements applicable to conditionally exempt small­quantity generators can be found in 40 CFR 261.5. Hazardous waste must be sent to a permitted treatment, storage and disposal facility (TSDF) – it can’t be transported along another road to another location of a campus for example. Generators must obtain an EPA identification number, prepare the waste for 3 transport, follow accumulation and storage requirements, manifest hazardous waste, and adhere to detailed record­keeping and reporting requirements. Conditionally exempt small­quantity generators are partially exempt from these requirements. Definition of Hazardous Waste RCRA defines "hazardous waste" as solid waste that, "because of its quantity, concentration, or physical, chemical, or infectious characteristics may: 1) cause, or significantly contribute to an increase in mortality or an increase in serious irreversible, or incapacitating reversible, illness or 2) pose a substantial present or potential hazard to human health or the environment when improperly treated, stored, transported, or disposed of, or otherwise managed." A "solid waste" under RCRA is not necessarily solid. "Solid waste" is defined as "any ... discarded material, including solid, liquid, semisolid, or contained gaseous material ..." The term "discarded" includes any material that is abandoned, recycled, or "inherently waste like.'' The term "hazardous waste" means any solid waste (as defined above) that: exhibits any of the characteristics of a hazardous waste (i.e., ignitability, corrosivity, reactivity, or toxicity as determined by EPA's Toxicity Characteristic Leaching Procedure (TCLP) test); · has been listed as a hazardous waste by EPA regulation; · is a mixture containing a listed hazardous waste and a nonhazardous solid waste; or · is a waste derived from the treatment, storage, or disposal of a listed hazardous waste. · Certain otherwise hazardous wastes are excluded from regulation. These include samples sent for testing and household waste. Satellite Accumulation RCRA regulation ­ a generator may accumulate up to 55 gallons of hazardous waste, or 1 quart of acutely hazardous waste, "at or near any point of generation where wastes initially accumulate which is under the control of the operator of the process generating the waste...."Limit the accumulation time to less than one year. Hazardous Waste Accumulation Area – maximum storage time is 90 days. The waste container must be in good condition, compatible with the waste, closed except if in use, properly handled stored and labeled. Drain Disposal of Hazardous Waste – permissible on if the drain flows to a wastewater treatment plant, not a septic tank system or storm sewer which flows to surface water, such as rivers or streams. Direct dischargers into bodies of water are required to have a National Pollutant Discharge Elimination Systems (NPDES) permit. Indirect dischargers, who discharge effluents into publicly owned sewage treatment works, do not need a 4 permit, but are subject to discharge conditions set by the local wastewater treatment authority. Empty Containers A container is considered empty if a maximum of no more than 2.5 cm (1 inch) of residue, or 3 percent by weight of containers less than 110 gallons, remains. An "empty" container, is no longer subject to RCRA regulation. If the container held acute hazardous waste, triple rinsing or equivalent measures are required before the container is "empty" within the RCRA regulations.Rinsing with water or a detergent solution is advised for all hazardous waste containers. Rinsates resulting from the cleaning of empty containers that contained acutely hazardous waste are themselves hazardous waste. Rinsate from hazardous waste may or may not be hazardous waste. In­lab Treatment. "Treatment" is very broadly defined by RCRA (40 CFR 260.10) to include "any method, technique, or process, including neutralization, designed to change the physical, chemical, or biological character or composition of any hazardous waste...." Basically, RCRA prohibits any treatment without a permit, with only very limited exceptions including: 1. Treatment studies – must be well documented 2. Treatment which is part of the experiment – allowed since the material has not been declared waste yet. 3. “Closed loop” treatment 4. Neutralization of waste that is hazardous only because of corrosivity characteristics. 5. Miscellaneous small­generator exemptions The Clean Air Act (CAA) – regulates emissions of sulfur dioxide, volatile organic compounds (VOCs), hazardous air pollutants (HAPs) and ozone depleting chemicals (ODCs). The list of stratospheric­ozone­depleting substances can be found at 40 CFR 82, Appendixes A and B to Subpart A. The list includes as "Class I" substances most common freons, carbon tetrachloride, and methyl chloroform. SARA TITLE III, COMMUNITY RIGHT­TO­KNOW AND EMERGENCY NOTIFICATION AND RESPONSE Under Title III of SARA, the Superfund Amendments and Reauthorization Act, facilities that use hazardous chemicals in their operations must maintain the Material Safety Data Sheets (MSDSs) required under OSHA's Hazard Communication Standard, submit copies of the MSDSs, provide inventories of hazardous chemicals, and report accidental releases to emergency planning authorities. The basic rationale for these regulations is twofold; the community's "right to know" what hazardous materials are present in facilities in their community, and the need for emergency response authorities and local fire departments 5 to know what substances are being used or stored in case they are required to respond to a fire, explosion, release, or other emergency. THE TOXIC SUBSTANCES CONTROL ACT The Toxic Substances Control Act (TSCA) is intended to control new or existing chemicals that may present unreasonable risks to human health or the environment. In 1976, Congress enacted this statute to fill gaps in chemical control not covered by other laws and agencies, such as the Federal Insecticide, Fungicide and Rodenticide Act (FIFRA), the Food and Drug Administration (FDA), and the Occupational Safety and Health Administration (OSHA). TSCA is not intended to overlap other laws that already regulate specified chemical uses. TSCA authorizes EPA to administer and enforce the rules it develops under TSCA. Before a company can manufacture or import a new chemical (a chemical not listed on the TSCA Inventory), it must file a PMN with EPA and allow the agency a specified period of time to assess the risks to health or the environment. Failure to do so can result in penalties as high as $25,000 per day of violation. It should be noted that importation is the same as manufacturing under TSCA. There is an exemption from the PMN requirement for chemicals used for R&D, or in a use regulated by another agency (such as solely for medical use regulated by FDA) One subpart of Section 8 of TSCA can affect R&D laboratories. TSCA 8(c) is the requirement to keep records of allegations of significant adverse affects of chemicals – skin rashes, allergic reactions respiratory effects, etc. 6