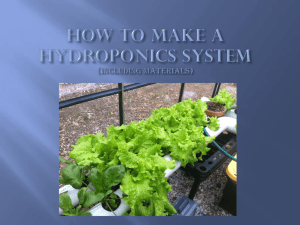

Materials Overview Bioplastic Container Cropping Systems

advertisement

Bioplastic Container Cropping Systems Materials Overview James Schrader - Iowa State University Round-1 Prototypes of Bioplastics and Biocomposites 20 Injection molded 10 Coated fiber Soy-Protein Based Carbohydrate Based PHA and PLA polymers and composites Dip-coated Fiber Containers • Paper, Coir, or Wood • Bioplastic coatings PLA = Polylactic Acid • Ingeo™ from NatureWorks LLC http://www.natureworksllc.com PHA = Polyhydroxyalkanoate • Mirel™ from Metabolix, Inc. http://www.metabolix.com Polyamide • Uni-Rez™ from Arizona Chemical http://www.arizonachemical.com PUR = Polyurethane • CUR 99 from Alberdingk Boley http://www.alberdingkusa.com Conclusions from Round 1 • Injection-molded bioplastics function as well as or better than petroleum plastic for crop containers. • Many of the bioplastics and biocomposites degrade in soil under normal landscape conditions. • Soy-based bioplastics release nitrogen and produce a fertilizer effect. They also improve root morphology. • Soy-based polymers must be blended with another biopolymer to improve durability and control the fertilizer effect Fertilizer Effect ~ Root Improvement @ 6 weeks 200 mL / week 150 ppm N Conclusions from Round 1 • Adding bio-based fibers improves processability, function, and degradation of injection-molded bioplastics - and decreases cost. • Coating fiber containers with bioplastics improves water-use efficiency and improves their function to resemble that of petroleum-plastic • Bioplastic and biocomposite plant containers should be cost competitive with petroleum-plastic containers. Round 2 - The Present Round “Improving and evaluating best 15 types from round 1” • 19 total bioplastics and biocomposites • 4.5” and Gallon - sized containers Materials in Round 2in Round Container Materials Evaluated 2 Container ID # Injec/on Molded Fiber Containers 1 2 3 4 8 9 20 23 24 6 10 11 13 19 Ingeo PLA Blends and Composites PHA + Soy (67/33) PHA & DDGS (80/20) PHA & Lignin (80/20) PHA + Starch (90/10, Mirel P1008) PHA + Cellulose (Aspen Research) PolyAmide Blends and Composites Coated Fiber Containers 27 28 29 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" 4.5" Mirel PHA Blends and Composites PolyAmide & DDGS (70/30) PolyAmide + PLA (70/30) PLA + Soy (50/50) PLA + Soy (67/33) PLA + Soy & DDGS (60/30/10) PLA + Soy & Lignin (60/30/10) PLA & DDGS (80/20) PLA & Lignin (80/20) PLA -­‐ Protein Compound (Aspen Research) Recycled PLA # 1 (Aspen Research) Recycled PLA # 2 (Aspen Research) 14 17 25 26 Petroleum Plas9c Controls Polypropylene (Standard for 4.5”) HDPE (Standard for Gallon) Paper-­‐fiber (Polyurethane) (ONE COAT) Paper-­‐fiber (Polyurethane) (TWO COATS) Paper-­‐fiber (UNCOATED Control) Totals: 16 Gallon Gallon Gallon Gallon Gallon Gallon Gallon Gallon Gallon Gallon 10 Material Characterization Processability Evaluations Greenhouse and Nursery Trials Landscape Evaluations • Container removed, crushed, and buried beneath roots Biodegradation in Soil Categories of Biocontainers 1. Containers biodegradable in soil (within a timeline of 1 to 2 years) 2. Containers not degradable in soil, but degradable by composting 3. Exceptional or durable containers that can be recycled - or will be carbon-negative if landfilled - carbon neutral if incinerated Questions ?