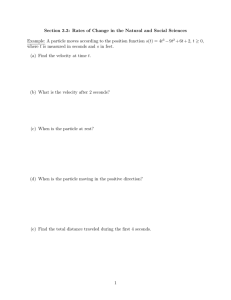

Wind Wave Tank for Experimental Investigation ... Enthalpy Transfer from the Ocean Surface ...

advertisement