Implementation of Remote Monitoring System ; 4.

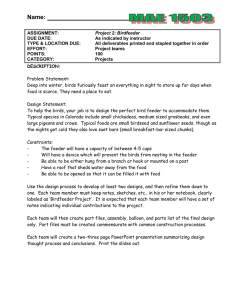

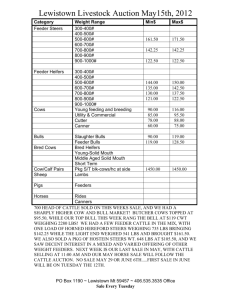

advertisement