Sara L. Ransom using Transmission Electron Microscopy

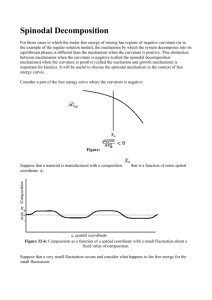

advertisement