Production Records Training Slide Notes Module I: Production Records

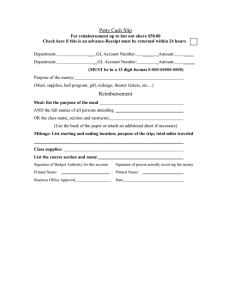

advertisement

Production Records Training Slide Notes Module I: Production Records Slide 1: Production Records ***General introduction of self, participants and purpose of the training.*** Slide 2: Training Outline Today we are here to learn what needs to be included on the production record form. In Module I, we will review the purpose of keeping accurate production records, as well as the resources we need to use to fill them out completely. Module II will provide a thorough overview of all the different parts of a basic Meal Production Record, which can be used for breakfast, lunch, and/or supper. Modules III and IV provide direction on how to use production records specific to Breakfast and Salad Bars. Slide 3: Module I As we begin this training, it will be helpful to have the listed handouts, available in your training packet, readily available as we review the resources needed to thoroughly complete production records in Module I. Slide 4: Production Records - Overview Production records are used to plan and control food production and need to be completed daily at the end of the meal service. Production records should not be removed from the school premises. Substitutions or menu changes can be made only if permitted by the Food Service Director. ***Click mouse/pointer for the remaining set of bullets.*** Production records provide the Local Education Agency (LEA) with the documentation of the types and amounts of food served for reimbursable meals, which are required under federal regulations for Child Nutrition Programs. During reviews, they are used by the Office of Child Nutrition to determine compliance with the nutrient standards and the meal pattern. Slide 5: Production Records – Overview There are many advantages for completing production records accurately. Thoroughly completed production records provide an accurate history of the food planned, prepared and served, which helps the Office of Child Nutrition verify compliance with program requirements and the Dietary Guidelines for Americans during on-site reviews. They can also increase savings by minimizing overproduction and plate waste. In addition, production records provide a student acceptance history that may help forecast how much to prepare for future menus. WVDE OCN Slide 6: Production Record Resources Many resources need to be utilized to fill out production records accurately. These resources include the NFSMI Basics at a Glance measurement worksheet, the Meal Pattern requirements and the Grains/Breads Chart. ***Click mouse/pointer for the next set of bullets.*** In addition, Nutrition Facts Labels, which provide required nutrition information, should be kept in an organized manner for all processed foods used in your menus. Sometimes, however, they are not available. In that case, a copy of the manufacturer’s Data Submission Form and Product Specifications, will provide the required information. ***Click mouse/pointer for the remaining set of bullets.*** Documenting the Product Code Number is also helpful in providing information about the product. Remember, for combination-processed foods, such as Breaded Nugget-Shaped Chicken Tenders, a CN (Child Nutrition) Label is required to determine how that product contributes to the meal pattern. Slide 7: Production Record Resources – Basics at a Glance Basics at a Glance is a very handy tool to laminate and keep posted in the kitchen for easy reference. It helps determine the correct serving utensils for proper portion sizes and saves time by calculating commonly used fraction-to-decimal equivalents, different sizes of scoops and steam table pans, etc. Slide 8: Production Record Resources – Meal Pattern The current meal pattern is divided into three grade groupings ***click mouse/pointer*** (grades K-5, 6-8 and 9-12) to provide age-appropriate servings to students. The meal pattern consists of five components (meat/meat alternate, grains, fruits, vegetables & milk) ***click mouse/pointer***. Under each component on the chart, the required daily minimum and weekly minimum/maximum amounts are indicated. There are four dietary specifications ***click mouse/pointer*** that must be met and these specifications are also listed on the new meal pattern. There are weekly average requirements for calories, sodium and saturated fat and a daily requirement for trans fat. Slide 9: Production Record Resources – Grains/Breads Chart ***Ask Participants:*** How do you determine the way in which a grain product contributes to the meal pattern? ***Answer:*** The Grains/Breads Chart is a useful tool that can be found in the Food Buying Guide on pages 3-14 and 315. You have a copy of it in your handouts. ***Explain the chart; left-hand column (Groups A-I), right-hand column (serving sizes by weight ((grams/ounces)).*** Grains/Breads contribute to the meal pattern by weight. This chart provides the minimum serving sizes by group (e.g. Group B contains most of the bread products). ***Ask the participants what 1 serving of bread should weigh.*** ***Answer:*** 25 grams or .9 ounces. The weight of all products can be found on the top portion of the Nutrition Facts Label. ***Provide additional examples, such as tortilla chips, pancakes, and rice. Also, discuss how items can contribute to a quarter, half or three-quarters of a serving.*** It is essential that you use this chart to determine how a grains/breads food product can be credited toward the grains/breads component. For more information on crediting grains/breads refer to the flow chart on page 3-7 of the Food Buying Guide. WVDE OCN Slide 10: Production Record Resources – Nutrition Facts Label Keep copies of the Nutrition Facts Label, including the Ingredients portion, for all processed foods, dairy products and grains/breads. The information on the Nutrition Facts Label is needed to conduct the CRE and SMI reviews. ***Click mouse/pointer*** As stated earlier, the weight of all products can be found on the top portion of the Nutrition Facts Label. ***Click mouse/pointer*** If a child should get sick, information from the Ingredients list is very important. Slide 11: Production Record Resources – Data Submission For & Product Specifications For products that do not have a Nutrition Facts Label, you need to ask for the manufacturer’s Data Submission Form and Product Specifications. This information is usually submitted with the bid agreement. Slide 12: Production Record Resources – Product Code Number, CN Label The Product Code Number is a universal identifier that provides a unique identity for a particular product to assist with tracking (e.g. food recall); it is a bold black number on the box that identifies the product. The CN Label is needed for combination processed food items to determine how the product contributes to the meal pattern. Slide 13: Questions? This is the end of Module I; I/we hope you have enjoyed this training and found it helpful. Are there any questions? End of Module I WVDE OCN Module II Slide 1: Meal Production Record ***General introduction of self, participants and purpose of the training.*** Slide 2: Training Outline As we begin this training, it will be helpful to have the blank, numbered and the completed HHFKA Production Records available for reference as we go through the step-by-step process of how to accurately complete a production record. In addition, a copy of the USDA Recipe for Bean Burrito (D-12A) and the Grains/Breads Chart will be useful in completing the sample production record. Slide 3: HHFKA Production Record Form ***Ask participants to pull out their blank and numbered HHFKA production record forms.*** This production record may be used for breakfast, lunch, snack and/or supper. Slide 4: The Menu Let’s look at how to fill out the meal production record using this lunch menu for Mountain Creek Elementary School. The menu includes a bean burrito with chunky salsa, corn on the cob, cantaloupe, lime sherbet and milk. Slide 5: Site Information (Step 1) The first step in completing the production record is to fill out the Site Information. First, indicate the grade group (K-5, 6-8, 9-12); then record the name of the school where the meal is produced. Central or base kitchens should keep records of the amount of food shipped to each satellite or receiving kitchen, as well as the total production for that site. Then, write the name of the person(s) completing the record. Each food service member is responsible for recording his or her part accurately. For example, if you are baking the items for the menu that day, you are required to complete all the documentation related to the baked items on the menu. The cafeteria manager is ultimately responsible for a complete and accurate production record. Next, enter the date the meal is served and finally, indicate whether Offer vs. Serve (OVS) is practiced. “Offer” allows students to choose a certain number of items from the meal (at least 3 of the 5 components). “Serve” requires students to take all components of the meal. “Offer vs. Serve” is encouraged for all grade levels. Remember, ½ cup of fruit and/or vegetable is a required component. For the purposes of this training, the grade grouping is K-5 and our school’s name is Mountain Creek Elementary. The Cafeteria Manager who is completing and verifying the record on September 20th, 2012, is ELC. This school practices OVS. Slide 6: Meal Information (Step 2) In Step 2, Meal Information, we need to circle the meal planned (Breakfast, Lunch, Snack and/or Supper) and indicate the number of meals planned for students, adults and total. Meals served cannot be documented at this time. Mountain Creek Elementary has about 500 students and 5 adults that eat school lunch on a regular basis. WVDE OCN Slide 7: Planned Menu (Step 3) In Step 3, list all Menu Items, including condiments and toppings (they contribute to the nutrient analysis); at the bottom of the Menu Item section, approved milk fat-content varieties are listed as a reminder to include the counts on the production record. Actual counts are required for dressings, condiments, fresh fruits, milk, cereal, and juice. With each Menu Item listed, document the Product Code/Recipe Number, the portion size, and the number of portions to be prepared. Under the Product Code/Recipe Number section, record the manufacturer’s name and product code if the item is a processed food. This is important because it identifies the specific product being used. The product code is usually the number on the box that is bold and black. If the item is a USDA or local recipe, record the recipe number in this section. Any menu item that is prepared with two or more ingredients needs to be documented as a local recipe. All recipes, USDA or local, must be recorded, standardized and include the meal pattern contribution and HACCP Critical Control Points. When stating the planned portion size for each menu item; i.e., 1 cup, 5” x 5” piece, 3 oz, etc., note that this is the actual size, weight or amount of each serving as planned. Base the amount to be prepared on student attendance and past meal production records. It is recommended to pad entrée portions by 20-25 servings and to pad fruit and vegetable portions by 5-10 servings. Using our example: For the first menu item, Bean Burrito, record the recipe number. This is a USDA recipe and the number is D-12A. If you look at the meal production record, 505 meals are estimated but the planned amount for the bean burrito is recorded at 530. For the next menu item, chunky salsa, record the manufacturer’s name and product code; 420 ¼ cup servings of salsa are planned. Corn on the cob is a frozen item and would be recorded simply as “frozen”. There is no need for a product code for this. Cantaloupe is a fresh item and would be recorded as “fresh”. The manufacturer’s name and product code would be recorded for the Lime Sherbet (Cherry Hill 2164). The dairy producer’s name (Broughton) is listed for milk items. WVDE OCN Slide 8: Meal Contribution (Step 4) For each menu item, determine how it contributes to the meal pattern under each meal component category. The meal pattern now consists of five components. There are a number of resources that can be utilized to determine how menu items contribute to the meal pattern. Information on how the menu items can be credited may be derived from the Food Buying Guide, Grains/Breads Chart, USDA recipes, standardized local recipes or CN labels. Look at the menu and record the meal pattern contribution for each item. Bean Burrito is a USDA recipe. If you take out the copy of the recipe and look at the second page under SERVINGS, it states that one burrito provides 2 oz. M/MA, ¼ c. Vegetable and 1.5 servings of Grains. A ¼ c. serving of 100% vegetable canned salsa counts as ¼ c. vegetable. The fresh corn on the cob would contribute ¼ c. vegetable and the ½ c. cantaloupe would contribute ½ c. fruit according to the Food Buying Guide. Lime sherbet does not contribute to any of the meal pattern components, so it should not appear in any of the meal contribution columns. ½ pint of milk would contribute 8 oz. of fluid milk. Any additional condiments and toppings need to be listed on the production record, even if they do not contribute towards the meal pattern. After determining the component contribution, it should be reviewed to ensure that the Meal Pattern is met. For grades K-5: The Bean Burrito contributes 2 oz. of M/MA, 1 ½ oz. eq. of Grains and ¼ c. Vegetable. The daily minimum of 1 oz. M/MA is met, as well the 1 oz. eq. for Grains. The ¼ c. of Vegetable, in addition to the ¼ c. serving of salsa and ¼ c. corn on the cob total ¾ c., meeting the daily vegetable requirement. The ½ c. serving of cantaloupe meets the ½ c. daily fruit requirement. 8 oz. of each of the milk varieties satisfy the 1 cup milk requirement. The production record is now complete until it is time to prepare the meal. WVDE OCN Slide 9: HACCP (Step 5) For Step 5, HACCP, it is recommended that temperatures be recorded on the production record to make them easy to find if necessary (food borne illness, complaints, etc.). Take temperatures of all food items that must be held at a particular temperature – hot food items that must stay hot, cold food items that must stay cold. Temperatures, along with the time at which they are taken, MUST be recorded on all potentially hazardous foods. More than one temperature is advised to ensure accuracy. In this particular menu, time and temperatures are recorded for the Bean Burrito, Corn on the Cob, and Milk. Slide 10: Served, Left, Disposed (Step 6) Step 6, Served, Left, Disposed, is completed after the meal. In the “Served” column, simply indicate the number of food items served to students and adults by portion size. In the example, 530 burritos were prepared; 480 were actually served; 50 were left over. This amount of leftovers should not be a normal occurrence. However, a virus is going around the school and there are a high number of absent students. The “Left” column should be the difference between the number of portions prepared and the number of portions served. The “Disposed” column is where you indicate how leftovers were disposed. Abbreviations for disposal codes are provided at the bottom of the production record. Once the meal service is over, you can record the number of Meals Served, located in the Meal Information box, next to the number of Meals Planned. Record the total count of students and adults who received a meal. Slide 11: Production Notes (Step 7) Step 7, Production Notes, provides a place to record any changes or substitutions to the menu, address attendance factors, record special diets or track food used per meal for inventory purposes. For example, if the cantaloupe on the menu didn’t arrive but you had bananas on hand, explain the substitution in this section. This section can also be used to document factors that affect meal participation, such as field trips, weather, assemblies, etc. In addition, in the case of special diets, if you had one child with a special diet, this space may be used to record the menu and portion sizes provided to the student. If more than one special diet, this information must be recorded in a notebook to ensure all menu items given for each student is recorded. According to today’s production record, a virus was going around and many students were absent. Additional staff were at the school for training. Slide 12: Completed HHFKA Production Record This is a look at the completed meal production record. Slide 13: HHFKA Production Records Remember, accurate production records are very important, reflect integrity and are REQUIRED. If records are incomplete or inaccurate, a review is not possible. Slide 14: Any Questions? This is the end of Module II. I/we hope you have enjoyed this training and found it helpful. Are there any questions? End of Module II WVDE OCN Module III Slide 1: Breakfast Production Record ***General introduction of self, participants and purpose of the training.*** Slide 2: Training Outline As we begin the Breakfast Production Record training, it will be helpful to have the blank and completed Breakfast Production Record handouts available. In addition, the color-coded copy of the Meal Production Record may also be helpful as a reference. Slide 3: Blank Breakfast Production Record Form ***Ask participants to pull out their blank breakfast production record forms.*** Like the Meal Production Record form, the non-shaded area is the part of the production record that should be filled out BEFORE and DURING breakfast preparation. The gray-shaded area is the part of the production record to be filled out AFTER breakfast is served. The Breakfast Production Record form has been specifically designed to help ensure that all of the information needed regarding breakfast production is recorded and documented accurately. Slide 4: The Menu Let’s take a look at how to fill out the breakfast production record using this menu for Valley View High School. The menu includes a yogurt parfait, oatmeal muffin square and an assortment of cereals, juice and milk. Slide 5: Breakfast Production Record, Steps 1 and 2 Like the Meal Production Record form, the first two steps to completing the Breakfast Production Record are simply filling out the Site and Meal Information. ***Click mouse/pointer for Step 1 to appear on slide.*** This Breakfast Production Record is for Valley View High School on 11/21/11 and is being completed by CP. ***Click mouse/pointer for Step 2 to appear on slide.*** Since this site is a high school, OVS is required. WVDE OCN Slide 6: Breakfast Production Record, Steps 3 and 4 ***Click mouse/pointer for Step 3 to appear on slide.*** For Step 3, Meals Estimated, enter the number of breakfasts planned (estimated) for students, adults and total. Enter grade group(s). Be sure to include all breakfasts served, including those that may be offered in the cafeteria, prepared as grab-ngo, and/or those that may be offered at another location and/or time in the school. Valley View High School currently has about 250 students and 10 adults participating in a traditional breakfast program. ***Click mouse/pointer for Step 4 to appear on slide.*** In Step 4, list all Menu Items, including condiments and toppings – they contribute to the nutrient analysis as well. Notice how this form is different from the Meal Production Record form by indicating that you need to list the individual cereals and juice served during the meal, in addition to the milk. It is not an acceptable practice to just write “Assorted Cereals” or Assorted Juices” – you need to be as specific as possible. Also, remember to record the manufacturer’s name and product code for processed foods and to record the USDA and/or local recipe number for foods made on-site. All recipes, USDA or local, must be recorded, standardized and include the meal pattern contribution and HACCP Critical Control Points. Using our example: The Yogurt Parfait and the Oatmeal Muffin Square are documented as a Local and USDA Recipe, respectively. Four different cereals are offered with the manufacturer’s name recorded. Apple, orange and grape juice by Tropic Delite are included on the menu and a variety of low-fat milk is provided by Springfield Dairy. WVDE OCN Slide 7: Breakfast Production Record, Steps 5 and 6 ***Click mouse/pointer for Step 5 to appear on slide.*** In Step 5, we need to state the planned portion size for each menu item; i.e., 1 cup, 5” x 5” piece, 3 oz, etc. Note that this is the actual size, weight or amount of each serving as planned. Remember to adjust portion sizes by grade groups, as they have different meal pattern requirements. At Valley View High School all of the menu items are offered in individual, pre-determined portion sizes based on one age group. ***Click mouse/pointer for Step 6 to appear on slide.*** For each menu item, determine how it contributes to the meal pattern under each meal component category. There are a number of resources that need to be utilized to determine how menu items contribute to the meal pattern. Information on how the menu items can be credited may be derived from the Food Buying Guide, Grains/Breads Chart, USDA recipes, standardized local recipes or CN labels. Look at the menu and record the meal pattern contribution for each item. The Yogurt Parfait, a local recipe, contributes 1 M/MA, 1 V/F, and 1 G/B. This is only known because the recipe was standardized to determine it’s meal pattern contribution. The USDA Recipe for Oatmeal Muffin Squares indicates that if the recipe is followed directly, 1 piece provides 1 serving G/B. Each of the pre-packaged cereals contributes 1 G/B serving and 4 oz of 100% juice equals ½ cup F/V. As always, ½ pint of milk contributes 8 oz. of fluid milk. Slide 8: Breakfast Production Record, Steps 7 and 8 ***Click mouse/pointer for Step 7 to appear on slide.*** In Step 7, document the number of planned portions for each menu item. Base the planned amount on student attendance and past meal production records. It is recommended to pad entrée portions by 20-25 servings and fruit/vegetable portions by 5-10 servings. If you look at the meal production record, 260 total meals were estimated for breakfast. The Planned/Prepared amount for the Yogurt Parfait, Oatmeal Muffin Squares and other menu items were based on primarily on how well they were received previously, as indicated on past production records. After the number of planned portions has been documented, the production record is complete until it is time to prepare the meal. ***Click mouse/pointer for Step 8 to appear on slide.*** For Step 8, Time/Temp, it is recommended that temperatures be recorded on the production record to make them easy to find if necessary (food borne illness, complaints, etc.). Take temperatures of all food items that must be held at a particular temperature – hot food items that must stay hot, cold food items that must stay cold. Temperatures MUST be recorded for all potentially hazardous foods. More than one temperature is advised to ensure accuracy. WVDE OCN Slide 9: Breakfast Production Record, Steps 9 and 10 ***Click mouse/pointer for Step 9 to appear on slide.*** Step 9, Comments, provides a place to record any changes or substitutions to the menu. Remember, special diets apply to breakfast as much as they do to lunch. If you have one special diet, this space may be used to record the menu and portion sizes provided to the student. If more than one special diet, this information must be recorded in a notebook to ensure all menu items given for each student is recorded. ***Click mouse/pointer for Step 10 to appear on slide.*** Step 10, Amount Used, provides an area for food service staff to track food used per meal or for inventory purposes. Slide 10: Breakfast Production Record, Steps 11, 12, 13 and 14 Steps 11, 12 and 13 are typically completed as one step after the meal, but for the purposes of this training, they are divided into separate steps. ***Click mouse/pointer for Steps 11, 12 and 13 to appear on slide.*** Step 11, Number of Portions Served, is simply the number of food items served to students and adults by portion size. Step 12, Number of Portions Left, should be the difference between the number of portions prepared and the number of portions served. Step 13, Disposed, is where you indicate how leftovers were disposed. Abbreviations for disposal codes are provided at the bottom of the production record. ***Click mouse/pointer for arrow to Disposed codes to appear on slide.*** ***Click mouse/pointer for Step 14 to appear on slide.*** Step 14, Meals Served, is the last area to complete. Once breakfast is over, enter the number of meals served in each grade/group category. Record the total count of students and adults that received a meal. Slide 11: Completed Breakfast Production Record This is what the Breakfast Production Record form would look like when completed. Slide 12: Any Questions? This is the end of Module III. I/we hope you have enjoyed this training and found it helpful. Are there any questions? End of Module III WVDE OCN Module IV: Salad Bar Production Records Slide 1: Salad Bar Production Record ***General introduction of self, participants and purpose of the training.*** Slide 2: Training Outline As we begin this training, it will be helpful to have the blank and completed Salad Bar Production Record examples available for reference as we go through the step-by-step process of how to accurately complete a production record. This session is a step-by-step training on how to accurately complete a salad bar production record using a new form. The new form has many fruits and vegetables listed to make it easier to complete. We will begin this training by reviewing some of the basics of providing safe salad bars. Slide 3: Salad Bars A salad bar is a good way to provide variety to any meal. It allows students to choose from numerous fruits, vegetables, whole grains and low-fat dairy items. To ensure the salad bar is kept safe and free from any food safety mishaps, food service personnel should be stationed at the salad bar – monitoring, replenishing, and keeping it clean, looking fresh and free from contamination. Slide 4: Salad Bars Setting up a salad bar takes some thought to ensure the right equipment and utensils are available. Working with the school’s maintenance department to determine the best location for the unit is always a wise choice. They will assist you in selecting a unit with the proper electrical volts. Now we will review some ideas to help set up a successful salad bar for your students. ***Click mouse/pointer for text to appear.*** In terms of equipment, make sure you purchase the right salad bar unit for your school. Some units are refrigerated and save time by not having to add ice or ice rolls to keep the foods cold and at proper temperatures. Some units have hot food bars to allow some hot foods to be offered as well. Hot foods should never be placed on a salad bar unit that does not have a heated food bar. Salad bar units may also be lighted or unlighted. Age-appropriate salad bar units should be purchased to allow students to serve themselves. Moveable units are important to allow food service staff ease in set-up, cleaning and moving to the best area of the serving line to promote student usage. All salad bars must have sneeze guards to protect the food from contamination and to comply with food safety regulations. ***Click mouse/pointer for text to appear.*** When considering utensils and accessories, containers and crocks, which contain the food, must be sufficient in size to avoid spillage into other food items. Containers should be removable for easy washing and have lids to protect the food while not in use. Tongs, ladles, and spoons must be long enough so they do not fall into the food, causing cross-contamination from student’s hands or sleeves. Slide 5: Salad Bar Production Record ***Ensure all participants have a hard (two-sided) blank copy of the salad bar production record.*** WVDE OCN To complete the salad bar production record, the following nine steps need to be completed: Site Information, Part of Meal, Number Planned, Foods Offered/Description, Prep/Unit, Time/Temp, Preparation Notes and Comments, Served, Left, Disposed, and Number Served. We will be reviewing each of these steps in more detail shortly. Slide 6: Salad Bar Production Record It is also important to note that the production record is two-sided. ***Click mouse/pointer for text to appear.*** Side One is categorized by fruits, vegetables, garnishes, breads/grains – fruits and vegetables should be the emphasis of the salad bar. The general description should include the ‘form’ of the food, how it is packaged, distinguishing characteristics, etc. Note that there is not a space for times/temps on this side, as it is not required for these food items for HACCP. ***Click mouse/pointer for text to appear.*** Side Two is categorized by meat/meat alternates, other items, condiments and dressings. HACCP does require times/temps for these items; a product name/description and/or recipe number should be included. E.g. Standardized Local Recipe Salads #21- Pasta Salad or USDA Ranch Dressing E-19. Slide 7: Salad Bar Production Record ***Click mouse/pointer for text to appear.*** Measurements on the production record can be in weight or count. Cheese, meat and some fruits and vegetables (mandarin oranges, green beans, etc.) are typically weighed. Larger, individual food items, such as apples and bananas, should be counted, with a description of the size (small, medium, etc.). ***Click mouse/pointer for text to appear.*** When listing ingredient quantities in a recipe, remember that an ounce measurement may be either volume or weight. Ounce in volume is referred to as fluid ounce (fl oz.); ounce in weight is termed ounce (oz.). One cup = 8 fl oz. of volume, but 8 fl oz. of different foods varies in weight. For example, 1 cup (8 fl oz.) of apple cider = 8.7 oz. in weight, 1 cup (8 fl oz.) of chocolate pudding = 10.1 oz. in weight. Slide 8: Production Record Form (Blank) Next, we will review the different sections of the salad bar production record, filling it out as we go along. A completed sample is provided for you so there is no need to try to fill out the blank copy. Notice that the blank copy you have is printed front-to-back. ***Click mouse/pointer for side two to appear on the screen. Show both sides.*** Slide 9: Production Record Form – Steps 1, 2, 3 ***Click mouse/pointer for arrow to appear.*** WVDE OCN In Step 1 you need to provide the Site Information - the name of the school or site is written in this area, as well as the date of the meal and name or initials of the person filling out the form. ***Click mouse/pointer for Step 2 to appear.*** Step 2 is where you indicate if the salad bar is Part of the Meal - Do all students have access to the salad bar? If so, it is included as part of the meal, so circle YES. If you do not allow all students to use the salad bar and have it as a separate meal, circle NO. ***Click mouse/pointer for Step 3 to appear.*** Step 3, Number Planned, is where you write in the number of students that usually participate in the salad bar. If all students have access to the salad bar, the number that was recorded for the main meal will also be recorded here. Slide 10: Production Record Form – Steps 4 and 5 ***Click mouse/pointer for arrow to appear.*** In Step 4, Foods Offered/Description, check off and/or write in which foods are being offered, as well as a description. The general description should include the ‘form’ of the food, how it is packaged, distinguishing characteristics, etc. On side one, ***shown on the top part of the screen***, describe if the fruits and vegetables are fresh, canned, frozen, etc. For canned and frozen products, indicating the manufacturer or distributor’s name is also helpful. The sodium or sugar level (no salt added, packed in its own juice, etc.) should also be noted on canned products. If an item is measured by count, indicate its size. It is very important that on side two ***on the bottom part of the screen***, which consists of many more of the processed items one can typically find on a salad bar, that you indicate the source of the product. The source may be the brand or product name, or where a specific recipe is from (USDA or local). Again, the sodium or sugar amount (no salt added, packed in its own juice, etc.) should also be noted on canned products. ***Click mouse/pointer for Step 5 to appear.*** Step 5, Prep/Unit, is where you indicate how much of each item is prepared for the salad bar. Always prepare the minimum amount to avoid waste at the end of the meal period. All foods that are on the salad bar must be disposed of unless they are pre-packaged items. Slide 11: Production Record Form – Steps 6 and 7 .***Click mouse/pointer for arrow to appear.*** Step 6, HACCP Time/Temp, is where the temperatures of various food items, and the time the temperature was taken, must be recorded. Temperatures are required for meat/meat alternates, prepared salads, condiments and dressings. ***Click mouse/pointer for Step 7 to appear.*** Step 7, Preparation Notes and Comments, is a designated area for food service staff to record any changes or provide general comments about the meal service that day (e.g. indicating a reason meal participation was decreased (field trip); power outages, 2 hour delay, etc.) Slide 12: Production Record Form – Steps 8 and 9 ***Click mouse/pointer for arrow to appear.*** WVDE OCN Notice that Step 8, Amount Served, Left and Disposed, is slightly shaded. This is to indicate that this section should be filled out after the meal has been served; record the amount of each food item that has been served, how much was left over and how it was disposed. ***Click mouse/pointer for the next arrow to appear.*** Notice the “disposed” codes that should be used at the bottom of the page. ***Click mouse/pointer for Step 9 to appear.*** Step 9, Number Served, is also shaded. Record the exact number of students that participated in the salad bar that day. Slide 13: Production Record Form – Completed This is a completed sample of a Salad Bar Production Record. ***Click the mouse/pointer to show side two. Participants should also have a copy of the completed sample of the salad bar production record.*** Slide 14: Questions? This is the end of Module IV. I/we hope you have enjoyed this training and found it helpful. Are there any questions? End of Module IV WVDE OCN