Document 11077007

advertisement

t^

HD28

.M414

ALFRED

P.

WORKING PAPER

SLOAN SCHOOL OF MANAGEMENT

Sequential Screening in Semiconductor

Manufacturing, I: Exploiting Lot-to-Lot

Variability

Jihong

Ou

and Lawrence M. Wein

WP# 3451-92-MSA

July,

1992

MASSACHUSETTS

INSTITUTE OF TECHNOLOGY

50 MEMORIAL DRIVE

CAMBRIDGE, MASSACHUSETTS 02139

Sequential Screening in Semiconductor

Manufacturing, I: Exploiting Lot-to-Lot

Variability

Jihong

Ou

and Lawrence M. Wein

WP# 3451-92-MSA

July,

1992

MIT, LIBRARIES

\UG 2 7 1992-

REOclvED

SEQUENTIAL SCREENING IN SEMICONDUCTOR MANUFACTURING,

I:

EXPLOITING LOT-TO-LOT VARIABILITY

Jihong

Ou

Operations Research Center, M.I.T.

and

Lawrence M. Wein

Sloan School of Management, M.I.T.

Abstract

We

address a problem of simultaneous quality and quantity control motivated by

semiconductor manufacturing. After wafers are fabricated, they are probed, or electrically

tested, ajid in

turing process.

some

cases the probing facility

Under

this

is

the bottleneck for the entire IC manufac-

assumption, we consider the problem of choosing the optimal

start rate of lots of wafers into the fabrication facility

front of the probing facility to

and the optimal screening policy

maximize the expected

good chips minus the variable fabrication and probing

profit,

costs.

which

is

in

the revenue from

The screening

policy decides

which wafers to discard and which wafers to probe. These decisions axe subject to capacity constraints at

approach

random

is

both the wafer fabrication and probing

facihties.

employed: the number of bad chips on a wafer

variable,

ing to another

where the

gamma

scaie

parameter

distribution.

We

fit

is

unknown and

is

An

empirical Bayes

to be a

gamma

lot to lot

accord-

assumed

varies

from

the yield model to industrial data and test the

optimcd policy on this data.

July 1992

SEQUENTIAL SCREENING IN SEMICONDUCTOR MANUFACTURING,

EXPLOITING LOT-TO-LOT VARIABILITY

I:

Ou

Jihong

Operations Research Center. M.I.T.

and

Lawrence M. Wein

Sloan School of Management, M.I.T.

This paper and

management

will focus

companion (Longtin

main

1992) address a particular quality

et al.

issue in semiconductor manufacturing.

consists of four

we

its

The production

of integrated circuits

and

stages: wafer fabrication, probing, packaging

final testing,

on the interrelationship between wafer fabrication and probing.

and

In wafer

fabrication, disc-like wafers that contain hundreds of integrated circuits, or chips, are

produced

(in batches, or lots, of usually

20 to 50 wafers) by a very long and complex

procedure involving hundreds of operations.

on a wafer

good

chips.

is

After fabrication

completed, each chip

is

probed, or electrically tested, to distinguish between defective chips and

Each wafer

is

then separated into

its

respective chips, and nondefective

chips are covered in a protective plastic during packaging. In final testing, the chips are

functionally tested under a variety of environmental conditions before being shipped to

customers.

Problem Description. To

and the key material flow

issues

motivate our model formulation, the process economics

need to to be

briefly described. Building a wafer fabrica-

tion faciUty, or fab, costs hundreds of millions of dollars,

and consequently, fab managers

are very concerned with maintaining high utilization of the bottleneck equipment, and

one of the biggest operational decisions

rate of wafers into the fab.

fab (due primarily to

details),

for the fab

manager

Because of the huge amount of

random

yield, rework,

and

pushing the start rate beyond a certain

1

is

to determine the start

statistical variabihty in the

tool failures; see

level,

which we

Chen

call

et al.

1988 for

the fab's effective

capacity, will result in unacceptably high levels of work-in-process inventory and long

lead times.

Despite the well-documented congestion that occurs

where the probing (we

visited several facilities

rather than probing)

facility,

in

the more generic term testing

will often use

not the wafer fab,

is

wafer fabrication, we have

the bottleneck that determines the

production capacity of finished goods. There are several reasons for this phenomenon: the

testing

equipment

is

very expensive (machines can cost three to four million dollars) and

the testing procedure

testing capacity

is

is

a very time consuming and labor intensive process. Furthermore,

sometimes labor constrained because companies are either unable or

unwilling to hire and train full-time employees in the face of uncertain future demand.

Although

commodity

relative costs

or

custom

and revenues depend greatly on the type of market

chips)

and other

factors, the variable testing cost per wafer

typically only several percent of total variable production cost,

wafer of nondefective chips

is

constrained, they can

to

is

an increase

sell

in profit.

is

and the revenue from a

roughly ten times the variable production cost per wafer.

Also, the yield in wafer fabrication, which

very low and erratic. Since

(e.g.,

many

is

the fraction of chips that are good, can be

facilities are

capacity constrained rather than market

anything they make, and any increase

in yield leads directly

Consequently, yield dominates the economics of the process and

the primary concern of fab managers.

Semiconductor manufacturers typically use an exhaustive testing

chip of every wafer

is

tested and

is

deemed

it

undergoes testing (unless

from a custom order that has already been

grain of mainstream industry thinking.

is,

every

defective or nondefective. Indeed, the thought

of simply discarding a completed chip before

"leftovers"

policy; that

filled)

In contrast, our

goes very

represents

it

much

against the

paper and Longtin

based on the following simple premise that has also been put forth

in

et al.

axe

Goldratt and Cox

(1984): profitability can be increased by preventing bottleneck equipment from working

on products that are already defective. In particular,

under an exhaustive testing

policy,

if

testing

is

the bottleneck operation

then semiconductor manufacturers can increase their

profits

by simultaneously

(1)

employing a sequential screening procedure that adaplively

discards, rather than tests, portions of wafers (or entire wafers or even entire lots) that are

thought to have a sufficiently low proportion of nondefective chips, and

start rate of wafers.

in

Of

course,

if

the rate of wafer starts

is

(2) increasing the

increased, so

is

the congestion

the fab and the production costs, and these two factors need to be taken into account.

To

test this premise,

we consider the

following problem of simultaneous quality

quantity control: determine the start rate of

lots of

and

wafers into the fab and find a sequen-

screening policy for the testing facility to maximize the expected long run average

tial

revenue from nondefective chips minus the variable fabrication and testing costs of wafers.

The two

controls are subject to constraints on the average effective capacity of both the

fab and the testing station;

strictive

we assume

that the testing capacity constraint

than the fab constraint when an exhaustive testing policy

is

is

more

re-

To minimize

in use.

confusion, a screening procedure in isolation will be referred to as a policy and a screening

pohcy coupled with

a start rate will be referred to as a strategy.

In practice, the resulting increase in profit that

tive to the exhaustive testing strategy

an optimal strategy

commonly used

in

industry (that

will

is,

an exhaustive

testing policy with a start rate that keeps the testing facility working at

capacity) depends greatly on two factors that will be discussed below:

congestion levels of the fab and the testing

and

(2) the

facility

nature of the yield variability. Indeed,

than the testing

facility

achieve rela-

its

effective

(1) the relative

under the exhaustive testing

if

under an exhaustive testing

the fab was more highly congested

policy,

then this policy might be

optimal, and hence sequential screening would be of no value. However, testing

performed after various key operations

tion

in

policy,

is

also

the fab, and often (for example, see the simula-

models of Atherton and Dayhoff 1985, Glassey and Resende 1988 and Wein 1988) the

bottleneck workstation in the fab

make many (up

is

the photolithography workstation, to which wafers

to twenty) visits during their processing. Thus, the

framework presented

here can also be used to perform sequential screening at key tests in the fab. That

start rate of wafers

is,

the

can be increased and undesirable wafers or chips can be discarded at

in-fab tests so that the bottleneck

procedure

this

type

II

may

not be as effective

errors are apt to be

often visual and

is

equipment works on higher quality

in

the fab as

more prevalent

in

it

is

the fab.

at probe, because type

at

an in-fab

to the bottleneck workstation.

We

test

may become

will hereafter

defective before

is

at

90%

of

its

effective capacity

and

assume that testing

is

when the exhaustive

is

correctly

is

next

its

visit

the bottleneck

operation, and more specifically, our numerical studies here and in Longtin et

that the fab

I

In particular, in-fab testing

not as discerning as electrical testing, and a chip that

found to be nondefective

However,

chips.

assume

al.

testing strategy

is

employed.

Yield Modeling.

We now

in wafer fabrication occurs for a variety of reasons, including short

particulate contamination (see

Osburn

heavily on the probing machines.

effective

After

if

difficult to detect visually,

life

yield

cycles,

and

and the industry

Intuitively, sequential screening will only

dependencies and/or nonuniformities

all, if

product

1988), misalignment of operations,

et al.

chemical imbalances. Also, defective chips are

relies

Low

discuss the nature of the yield variability.

in yield

be

can be identified and exploited.

every chip processed by the fab had the same probability of being defective,

independently of

all

other chips, then sequential screening would be fruitless. However,

several types of dependencies do exist and, indeed, one of our primary goals in this pair of

papers

and

is

to analyze industrial data

and determine which dependencies are most prevalent

easiest to exploit.

Recall that chips are produced on wafers, and wafers travel through the fab

Dependencies

(1)

may be

present at

all

in lots.

three levels (lots, wafers, chips), including

dependence across consecutive

lots:

the yield of consecutive lots

may be

positively

correlated because of machines that go in and out of control, or batch operations, such

as diffusion or oxidation, that simultaneously process multiple lots;

(2)

nonuniformity

than others;

in

chip type:

some chip types may be inherently

easier to

produce

(3)

a lot

dependence of wafers within a

may be due

positive serial correlation of wafer yields within

lot:

one or more

to operations that simultaneously process

lots of wafers,

or to wafer- by- wafer operations that incur a joint set-up for an entire lot;

dependence of neighboring chip locations on a

(4)

found

(see Mallory et

in clusters

wafer,

defective chips are often

1983 for empirical data), which

al.

may be due

to

processing or particulate contamination;

(5) radial

nonuniformity on a wafer:

handling and processing can cause a donut-

shaped yield with more defective chips on the edge of the wafer and. to a

in

the center of the wafer (see Ferris-Prabhu et

al.

1987 for empirical data): and

dependence of a chip location across wafers within a

(6)

lesser extent,

lot:

mask

and batch

defects

operations can cause the yield of a chip location to be positively correlated across consecutive wafers.

(i)

Furthermore, sequential screening can be performed at

all

entire lots of wafers based on the yield

lots, (ii)

from previous

on the yield of previously tested wafers from the same

lot.

three levels:

or

(iii)

we can

wafers in a

We

dependency

wafer fabrication; since a wafer fab

not very prevalent

is

in

do not pursue screening of type

flow line operation, lots that are processed together in the

lot

based

chips on a wafer based

on the yield of previously tested chips.

(1)

discard

(i)

is

same oven during a

because

far

from a

particular

batch operation tend to go their separate ways and do not arrive together at the testing

facihty.

type,

Also,

all

the industrial data sets that we analyze contain lots of only one chip

and hence nonuniformity

(2) will not

be addressed. However, this factor could be

addressed in our framework by developing a different yield model

Our two

studies

dencies (3)-(6).

randomness

ity in

mean

The

employ sequential screening

factors underlying

of types

dependency

(3),

(ii)

and

for

each type of chip.

(iii)

to exploit depen-

coupled with the high degree of

in the

production process, lead to a significant amount of lot-to-lot variabil-

yield.

In this paper, sequential screening of type

lot-to-lot variabiUty.

Our

yield

(ii) is

model assumes that the number

employed

to exploit

of defective chips

on each

wafer in a given

lot

and scale parameter

(3 is

unknown and

an independent

is

fi.

An

varies

dently from a (different)

setting decides

when

empirical Bayes approach

from

lot to lot; for

gamma

each

lot,

prior distribution.

variable with shape parameter

is

used, where the scale parameter

the parameter 3

A

in this paper.

chosen indepen-

is

sequential screening policy

Bohn (1991)

is

used to estimate the parameters

Since the primitive empirical data

in

Bohn

is

wafer

and temporal dependencies described

maps

in this

Appendix

(see the

and model the chip

yield by a

in (4)-(6).

of that paper for

Markov random

Longtin

et al.

for the yield

number

the

defective chips on each wafer, this data cannot be used to analyze the

spatial

q

to discard the remaining wafers in a lot.

Industrial data from

model

gamma random

of non-

more detailed

analyze over 300

some e.xamples) from two wafer

field,

which

is

fabs.

a stochastic model that

allows the probability of a chip being nondefective to depend on the resulting yield of the

neighboring chips.

A

variety of sequential screening strategies of type

(iii)

are proposed

that discard individual chips on a wafer. In summary, the present paper employs sequential

screening at the wafer level to exploit lot-to-lot variability and Longtin et

al.

employ

sequential screening at the chip level to exploit detailed spatial dependencies within a

lot.

The two key

spatial

aspects of yield modeling that we focus on, lot-to-lot variablity and

dependence on and across wafers, have received very

modeling hterature.

We know

of

little

attention in the IC yield

no models capturing the former aspect and Flack (1985)

appears to contain the only yield model that explicitly accounts for spatial dependence

of chips

on a wafer. Nearly

the existing yield literature (see

all

Cunningham 1990

for a

recent survey) calculates the proportion of nondefective chips on a wafer by considering

the chip axea and density of point defects on the wafer. These derivations lead to a two

parameter distribution (the negative binomial distribution, which describes a Poisson

random

variable mixed with a

fitted to the

mean and

gamma, appears

to

be the most

variance of the empirical data for the

chips per wafer. According to

Cunningham, the goal

of

effective) that

number

most of the chip

can be

of nondefective

yield

modeling

research has been to predict costs and actual yields, and to determine the appropriate

level of circuit integration.

appears to be the

to

first

Albin and Friedman's (1989) work on acceptance sampling

employ a

yield

model

parameter distribution (the N'eyman type A. which

model the number

they use a two

in a quality control context:

is

a Poisson

compounded

Poisson) to

on a wafer. Because they were interested

of defective chips

in

quality

control issues rather than circuit design issues, they directly modeled the yield without

resorting to the defect density and chip area, and

Summary

tially

The optimization problem addressed

of Results.

in this pair of papers.

in this

paper

essen-

is

an optimal stopping problem embedded within a mathematical program, and the

optimal solution

is

determined numerically by solving a

stopping problems. Since the optimal strategy

optimal fixed sample

after

we do the same

where a

size strategy,

fixed

which the controller either discards or

is

parameterized optimal

series of

difficult to calculate,

number

we

also find the

of wafers from each lot

tests all the

remaining wafers

is

tested,

Five

in a lot.

of Bohn's industrial data sets are used to estimate the parameters of the yield model,

and the two proposed

maximum

the

policies are derived for all five

data

sets.

For our parameter values,

possible profit increase that an optimal strategy can achieve relative to

the exhaustive strategy

commonly used

in

industry

is

between 11.1% and 12%; the exact

upper bound cannot be mentioned without revealing the true

The

fixed

sample

size strategy

profit increase over the five

randomly

sets, respectively.

also tested

on the actual data

in a

simulation study.

shuffling the wafers in a lot, 100 lots of wafers are generated

the five data

sets.

If

Bohn's wafers.

and the optimal strategy achieve a 2.2% and 2.5% average

data

These two strategies are

yield of

from each

By

lot in

the yield model underestimates the average number of discarded

wafers per lot in the simulation study, then the testing facility will be underutilized and a

suboptimal strategy

is

obtained.

If

discarded wafers, then the testing

the yield model overestimates the average

facility will

number

of

be overutilized, and an infeasible solution

can result. Under the fixed sample size strategy, the model accurately predicts the average

number

of discarded wafers per lot,

and an average

profit increase of

1.2%

is

achieved.

Under the optimal

model underestimates the average number

strategy, the

of discarded

wafers by an average of 2.5% over the five data sets, which results in an average profit

decrease of 0.7%.

In

since

summary, the

it

is

much

is

size strategy

easier to derive

analytical model,

We

sample

fixed

and appears

and

to be

to

may be

implement,

preferable to the optimal strategy,

performs nearly as well on the

it

more robust when faced with the actual data

sets.

believe that the discrepancy between the theoretical results and the simulation results

due primarily

parameter

q.

to the

assumption that

the same data set have the same shape

Hence, a relaxation of this assumption

more accurate estimate

lead to a

all lots in

more

of the average

effective

and

number

is

probably required to obtain a

of discarded chips per lot, which should

reliable strategy.

The

profit increases reported here are

relatively small and, in particular, are significantly smaller the the increases achieved by

screening at the chip level in Longtin et

a

1%

al.

However, readers should keep

in

mind that

increase in revenue minus variable cost can represent millions of dollars annually.

Also, since the fixed cost

would translate

into a

component

much

is

1% improvement

so large in this industry, a

larger percentage

improvement

in

here

a company's reported

profits.

The remainder

of the paper

is

organized as follows. In Section

I,

the yield model

is

described in detail, and the modeling assumptions are compared with the conclusions of

Bohn's empirical study. The stochastic optimization problem

The optimal

fixed

sample

size screening strategy

sequential screening strategy

Section

7 of

5.

is

is

derived in Section

Concluding remarks on

this

found

4.

is

formulated

in

Section

Section 3, and the optimal

in

Numerical results are reported

paper and Longtin et

2.

al.

can be found

in

in Section

the latter paper.

1.

The Yield Model and

Our yield model assumes

Industrial

that the

number

Data

of defective chips

on each wafer

in

a given

lot

is

J.

an independent

An

gamma random

empirical Bayes approach

for all lots

is

is

parameters a and

h.

gamma

chosen independently from a

The two gamma

lot

gamma

gamma

(a

+

is

the

prior distribution with

distributions form a conjugate pair,

are found to be defective, then 3 has a

1

scale parameter

same

to lot: for each lot. the value of

ia.b) distribution prior to testing a wafer,

Figure

q and

used, where the shape parameter q

but the scale parameter J varies from

the parameter J

J has a

variable with shape parameter

a,b

+

and

if .r

if

known

the parameter

chips on the wafer

x) posterior distribution.

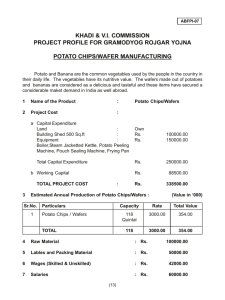

Die Yields of 11 Batches from Factory

CI

of

good

on each wafer of each

chips, or die.

Bohn. which displays a summary of data

to a lot of wafers

lot.

In Figure

we reproduce Figure

1.

Cl. Each column in Figure

corresponds

and each point represents the number of good chips on

a particular

set

essentially contains 11 yield histograms, one for each lot.

1

Ccime to the following three conclusions concerning his 11 data sets:

of each lot varies considerably from lot to lot (e.g..

there

lot

is

variabihty

(i.e..

compare the

considering the

gamma-gamma

we performed our

pair,

binomial pair and the gamma-Poisson

intuitive appeal, since the

integer between zero

and

(iii)

compare the second

number

of

and the number

pair: the

specifically,

the five data

sets.

lot.

ratio over all 53 lots

was

is

less

than (equal

the controls derived from these two

\-ield

modeled as

ein

However, the binomial and

lot

variabihty of chip yield.

number

of the

7.6

30.3. In contrast, the corresponding \ariance- to-mean ratio

respectively) assumption

explicitly

and determined the variance- to- mean

The average

In fact, before

this effect.

is

on a wafer.

we calculated the mean and variance

each wafer of a given

yield.

beta-binomial model, in particular, has

bad chips per wafer

of chips

mean

entire analysis using the beta-

Poisson assumptions significantly underestimate the within

of

good chips on

ratio for each lot in

and the range was

1.8 to

under the binomial (Poisson.

to. respectively) one.

Consequently, when

models were tested on the actual data, too

wafers were discarded at the testing facihty. which led to a significant reduction

in overadl profit.

level of

within

the

high:

is

yield

lots): (ii)

certainly captures the lot-to-lot variabihty in

However, plenty of other conjugate pairs would also capture

mamy

two

mean

Bohn

lots).

The gamma-gamma model

More

last

lot variability (e.g..

the

(i)

the vertical spread of points in each column)

a high variation between lots of within

and seventh

of

1

wafer; hence. Figure

within

1

within

lot

.Although the

lot variabihty.

variabihty.

scale peirameters are

it

gamma-gamma

is

conjugate pair captures the substantial

unable to capture the high variation between

Perhaps a gamma- gamma model

unknown would capture

this effect:

prevented us from pursuing this avenue. In summary, the

the effects in conclusion

(i)

and

(ii),

in

which both the shape and

computationad considerations

gamma-gamma model

but does not capture the

10

lots of

effect in

captures

conclusion

(iii).

To

further investigate the validity of our model,

data sets

This

is

may

on the actual

note that the number of wafers

in

a lot

is

not constant in Figure

due to the scrapping of entire wafers during fabrication. Hence, we also assume

that each wafer in a

has a certain probabihty of being scrapped during fabrication,

lot

so that the size of a lot exiting the fab

2.

test the derived policies

in Section 5.

Finally, readers

1.

we

a binomial

is

random

variable.

Problem Formulation

In this section,

we mathematically formulate the optimization problem described

the Introduction, and pictured in Figure

and each wafer consists of

with probability

q.

M

chips.

and hence the

variable with parameters L and

when the

lot arrives to

1

Each wafer

lot size

— q.

Each

2.

/

lot

the testing faciHty.

entering the fab contains I wafers

in a lot

is

scrapped during fabrication

of a wafer exiting the fab

Since the exact

it is

in

number

is

a binomial

of wafers in a lot

random

is

known

natural to use this information to develop

an optimal screening policy. However, this would require us to derive a different optimal

screening pohcy for every possible value of

more

difficult to

compute and harder

our screening policy to

more than

/

differ

this

which makes the optimal solution much

implement

lot to lot.

wafers can be tested from a

about 5-10% of their wafers,

in

from

to

/.

lot

in practice.

Instead,

we do not allow

except for the obvious constraint that no

with

/

wafers. Since

most fabs

t\-pically scrap

assumption should not lead to significant degradations

performance.

untested wafer?

scrapped

qlA wafers week

'

good wafers

TESTING

(l-q)LX wafers«'weeK

X lots/week

Mj wafers. week

bad wafers

Figure

2.

The semiconductor manufacturing

11

faciHty.

For a typical

=

wafer, for n

the

u„

u

=

/.

1

and

let .s^

=

let

Xn be the number of defective chips on the nth

Ill=\

be the total number of defective chips on

J^k

=

n wafers. Let the decision variable u„

first

=

exiting the fab.

lot

the nth wafer

if

(ui,U2,

....

where u„

the nth wafer

be discarded. A screening policy

=

for

n

>

=

For n

/.

1

/,

g(xn,u„)

=

=

and

defined by the vector

is

0.

The

^in

depends on

profit

generated

if

u„

=

0,

if

u„

=

1,

(i:

<

r{M r

to be tested

is

''

where

is

the decision

only through the sufficient statistic 5„_i, where ^o

(xi, ...,Xn_i)

bv wafer n

ul).

to

is

if

1

-

ir,)

ct

the revenue received from a good chip and cj

is

is

the variable testing cost per

wafer. For a given policy u. the expected profit from testing one lot of wafers

is

L

V{u)

=

E[Y,g(^n.Ur,)l

(2)

n= \

and the expected number

of wafers tested per lot

is

N{u) = E['tunl

(3)

n=l

where both expectations are over the random variables

definition of

and

//„.

The problem

decision variable

A,

which

the

is

of finding a screening policy u that

of simultaneous quality

We

its effective

levels will

maximizes

(2)

is

is

embedded

in

the

number

of lots introduced into the fab per week.

assume that

if

let

an optimal stopping

and quantity control involves one more

and two extra constraints. The decision variable

capacity be ftp lots per week and

per week.

which

(xi,...,j().

Our problem

problem.

/,

is

the

lot start

Let the fab's effective

the testing facility's effective capacity be

the rate of work entering either of these

capacity, then unacceptably high lead times

rate

and work

in

hj wafers

facilities

exceeds

process inventory

be incurred. Hence, the two constraints are

and

XN{U) <

12

fiT.

(5)

Our optimization problem

to choose the start rate A

is

and a screening pohcy u

to

maximize

\{V(u)-cr)

subject to constraints (4) and (5), where Cf

We

conclude

any testing

is

this section

is

the variable fabrication cost per

lot.

with some assumptions on the problem parameters. Before

performed, the a priori expected number of defective chips on a wafer

E[Xn]

=

To ensure that

this

quantity

positive,

is

—

(7)

I

we need

to

assume that

the parameter estimates obtained from Bohn's data

exhaustive testing policy by u

V'(u^)

,

is

-.

a

for

(6)

Section

in

a

>

5.

1,

If

which holds

we denote the

then

=

(1

- q)L[r{M -

- CtI

-^)

a —

(8)

[

and

N{u^) = {\-q)L.

We

(9)

assume

^^

(1

so that the testing facility

is

(101

-q)L

the bottleneck under the exhaustive testing policy, and

r(A/-^)-cx>-^.

— q)L

a —

so that exhaustive testing

3.

is

(11)

(1

I

profitable.

The Optimal Fixed Sample

Size Screening Policy

Since the optimal solution (A,u) to problem (4)-(6)

is

difficult to obtain,

ourselves in this section to a fixed sample size screening policy, which

Under

this strategy, the

number

of wafers tested

13

from a

lot is

is

we

restrict

denoted by

min{n,/}.

If

u"-

.

the total

number

of defective chips found in these wafers

remaining wafers

the

in

than or equal to B. then the

less

is

are tested; otherwise, the remaining wafers are discarded.

lot

Standard calculations show that

6-^7'^"^

+ (n-l)a)

r(a

,

..

'""' ^^'-'^ r(a)r((n-l)a)(6 + .„_,r<"-"-'

is

the probability density function for the number of bad chips on the

tested,

first

n

—

1

'

wafers

and

=—+

^x„|s„_i

a

is

'

'

the expected

number

chips are found on the

testing facihty has

/

(n

—

i)Q

—

(13)

1

of defective chips on the nth wafer, given that Sn-i defective

first

wafers

—

n

is

I

wafers.

.Also,

the probability that a

lot

entering the

given by

\

L

=

H{1)

I'-'iL-l)".

(14)

"

/

Hence, the expected profit per

V^K"^)

lot of

wafers

is

= J2HU){rl{M-E[x^])-lcT}

1=0

+

X^ //(/)r{n(M-£[x„]) + (/-n) /

-

^

//(/)cT{n

+ (/-n)

-

£[x„+,|5„])/(.sjrf.s,}

(15)

f{sn)dsr,}

/

-

l=n+l

and the expected number

iV(t/"-^)

(A/

of wafers tested per lot

= f^

//(/)/+

is

X^ //(0{n + (/-n) /

f(Sn]dsn}.

(16)

Thus, problem (4)-(6) reduces to

max

subject to

A(V(u"'^)

A

<

c/r)

(1")

(IS)

/zf

AAr(u"'^)

14

-

<

MT,

(19)

which

is

equivalent to

max

mm{fiF.fiT/y{u''-'')}{Viu'''")

-

cp).

(20)

Since a closed form solution to (20) appears to be unattainable, we exhaustively

enumerate over the integer values {n.B

solution.

The

V(u-^)

:

<

n

< 1:0 < B < n.M)

to find the optimal

calculations are considerably streamlined by observing that

=

V{u--^-')+ Y. H{l)T{l-n)l

L

-

.B

f{Sr.)ds^

(21'

= .V(u-s-i)+ Y. H[l)[l-n)r f{sjds„.

(22)

Y, H{l)cT[l-n)

/

{M-E[x^^,\sr.])f{sr,)ds^

/

=n+l

and

A'(u-S)

Hence,

for

each B. only /g., £'[j„+i|5n]/(5„)(is„ and fg_^ f(Sr,)dsn have to be calculated.

The Optimal

4.

Solution

In this section, a computational procedure

is

essentially

First

is

developed to solve problem

(4)-(6).

which

an optimal stopping problem embedded within a mathematical program.

we reformulate the problem

into the equivalent two-step maximization

problem

max \{V\-cp)

(23)

0<A<MF

where

Vx

=

maxV(u)

subject to iV(u)

Proposition

only

if

u'

is

1.

(A*.u*)

is

(24)

<

^.

(25)

an optimal solution to problem problem (4)-(6)

an optimal solution to problem (24)-(25) with A

15

=

A* in (25),

if

and

and

A*

is

(he optimal solution to (23).

The optimal objective function value

is

the

same

for

both

problems.

Proof.

with A

=

(X\u')

If

A' and, for

an optimal solution to problem

is

any screening policy u satisfying

(4)-(6), then u' satisfies (25)

this condition,

we have

X'{V{u-)-cp-)>\-{V(u)-cr)

(26)

or

V{in >

Hence, u'

is

V{u).

(27)

an optimal solution to problem (24)-(25) with A

=

A' in (25),

and

V'(u")

=

Vx'.

Observe that

X-{V(u')-Cf)>\{V[u)-cr)

for all A

and

u satisfying (4)

and

(5).

(28)

Fixing A and maximizing over u subject to (25)

yields

^'{Vx'-cf)>\(Vx-cf)

for all A

<

such that

A

<

optimal objective function value

Conversely,

u'

if

is

Therefore, A*

f.if.

is

is

(29)

an optimal solution to (23) and the

the same for both problems.

an optimal solution to (24)-(25) and A*

(23), then they jointly satisfy constraints (4)

and

(5).

is

an optimal solution to

For any other feasible solution

(A,u) to (4)-(6), we have

XiViu) - of) < A(Vx - cr] < X'{Vx' - cp)

which implies that (A*,u*)

function value

is

the

same

is

for

=

X'(V{u')

-

c/r),

(30)

an optimal solution to (4)-(6), and the optimal objective

both problems.

I

Let u° be the screening policy that maximizes the function V(u) defined

Maximizing V(u)

is

an optimal stopping problem and

section.

16

will

be discussed

in

(2).

later in this

Proposition

and

\'

=

<

2. If .\'{u°)

the optimal solution to (23)-(25)

ht/i-I-f- f/^en

is

u'

=

fj.f.

Proof. Since the screening strategy «° maximizes V{u) with no side constraints,

also

maximizes (24)-(25)

for all A

that u° optimizes (24)-(25) for

profitable,

and hence

I

(ti°)

Thus, when .V(u°)

<

We now

/ir/.V(u°)].

[0.

G

A

all

>

6

[0,/i/r].

and setting

A

By

=

Since N(ii°)

<

^ij/nr-

^ip

all

A

€

[0.

is

I

not used to

is

it

follows

optimizes (23).

its

full

effective

obtained by solving a single optimal stopping

is

consider the more interesting situation where N(u^)

u° optimizes (24)-(25) for

it

(11). the exhaustive testing policy

jij/np. the probing facility

capacity, and the solution to (4)-(6)

problem.

u°

//T/^'(»°)]. (23) can be replaced

max

\{\\-cf).

>

j.ljI i.Lf.

Since

by

(31)

mt/.V("°)<a<mf

If

problem (24)-(25) can be solved

efficiently for a given A,

over A G [/ir/.V(u°)./i/r] for the largest value of A(Va

to our original problem.

Since (24)-(25)

is

—

then a one-dimensional search

cp) will yield an optimal solution

a constrained optimal stopping problem,

we

solve this problem by employing a Lagrangian approach. Let 7 be the Lagrange multiplier

for constraint (25)

and define

u„

=

0.

ifu„

=

l.

if

5"'(x„,{in)

=

(32)

<

r(iV/-x„)-CT-7

Notice that 7 plays the role of an additional testing cost, so that the total testing cost

per wafer

is

cj

+

7.

Define the Lagrangian function

Viu)

=

V{u)-tN{u)

=

£[^^(x„,u„)l-7^(u)

L

n=l

=

E[X;g-(x„,u„)],

(33)

n= l

and consider the Lagrangian problem

maxV^(u).

U

17

(34)

Proposition

7

>

0,

Lagrangian problenn for some

3. If the screening policy u'{f) solves the

and

vV(u-(7))

then u'{f)

is

= y.

(35)

the optimal solution to problem ('24)-(25).

Proof. For any screening strategy u satisfying

V(u)

(25),

<

V'(u)-7iV(u)

<

V{u'it))-fN{u'{f)) +

=

V'(u-(7)).

+

7^

f^

(36)

I

Since 7 enters the Lagrangian problem as an additional testing cost,

to

show that the optimal objective function value

function of 7.

The

in (34)

proof of the following proposition

that the optimal expected

nonincreasing function of

number

on

this conjecture has

not hard

is

a continuous nonincreasing

this fact

of wafers tested per lot N{u'(f))

Although

7.

relies

is

it

and the conjecture

is

also a continuous,

been borne out

in

our numerical

study and seems as intuitively obvious as the continuity and monotonicity of the optimal

awkward expression

objective function value, the

from providing a rigorous

Proposition

4. If

N(u°) > nxl I-lf- ^^^" there

As 7 increases from

the optimal solution to (34)

conjecture

Since

By

<

is

is

to

Proposition

3,

<

exists a

=

to discard

all

is

that u'(^)

wafers

decreases from V{u°) to

when 7 = rM.

from iV(u°) to

N{u°), there must be a 7 € (0,rM]

u'{^)

7G (O.rM] such

is

^f.

rM, V^(u*(7))

correct, A'^(u'(7)) decreases

/xt/mf

has prevented us

proof.

an optimal solution to (24)-(25) with start rate \

Proof.

for N{u'{'y)) in (52)

Similarly,

as 7 increases

for

0, since

from

an optimal solution to (24)-(25) with start rate A

to

=

which N(u'(^))

if

=

our

rM.

/ir/zT-

fip-

I

Propositions 3 and Proposition 4 can be combined to develop a search procedure

for solving

problem

(4)-(6).

that 7 for which ;V(u'(7))

For fixed A € [ij.t/N{u°), hf], we solve (34) and search for

= ^iT/^

Proposition 4 guarantees the existence of such a

18

7

in

the interval [O.7]. Then, we evaluate the objective function

let

A

=

ij.t/N{u' {-))).

By Proposition

3,

"'(7)

and the objective function

this value of A.

For each 7 G [0,7]. we solve

7.

(31) can be evaluated.

over 7 G [O.7]

is

~

<7)-^-/'f] is

to (24)-(25).

7 G

all

/ij/-^-

Thus, one search

are searched.

[0,*/]

=

))

optimal start rate A' to (31) and the optimal

sufficient to find the

screening policy u'

end of

searched as

and

Since for every

A G [^t/-V(u°).^f] there exists a 7 in the interval [0,7] such that .V(u'(-

every A G [^r/(l

('i-i)

the optimal solution to (24)-(25) with

is

in

for

However, the search over A can be

a A' that has the largest objective function value.

accomplished simultaneously as we search over

and search

in (31)

Readers can find an outline of

this

algorithm

at the

this section.

We now

focus on solving the Lagrangian problem (34). Let

1

be the probability that a

n

^

I

-^(""1^''-'

lot

has more than

/

r(a + na)

= r(a)r(a + (n-l)a)

denote the posterior probability density

(6

on the

profit

first

obtained from wafers n

+

for the

+

3„-i)"^'"-"-(r„)-^

+

(6

given that Sn-i bad chips are found on the

expected

wafers, and let

+ xj-'^^

.„.,

number

-

n

first

1

""

'

"

^^^^

^'

bad chips on the nth wafer.

of

wafers.

1,...,I. given that Sn

If V'^*'(5n)

represents the

bad chips were detected

n wafers, then u'[-)) and V"'(u*(7)) can be found by solving the dynamic

programming equations

V^{sl)

=

V„''(5„)

= max{0,G(n)

(39)

/•oo

/

[r{M - x^+i) - ct - f

+

l^+.isn

+

Xn+i)\f{Xn+i\sn)d.r^+,}.

Jo

n

= L-l

and

1.

(40)

/•oo

V^(u)

=

^(7(0)

= max{0,G(0)

After n wafers have been tested,

If

/

[r{M -

i^)

-

ct

-

1

+

(41)

V^''{xi)]f(xi)dxi}.

we can discard the remaining wafers and obtain no

the lot has more than n wafers, then we can continue testing;

j„+i bad chips, then the immediate profit

is

19

r{M -

J„+i)

if

wafer n

-07-7

+

1

profit.

contains

and the expected

future profit

Vn+ii^n

is

+

-^n+i)-

These equations

optimal solution to (34), which are discussed

Proposition

The optimal

5.

u\ =

=

u-„

n

is

(ui(7),

...,

u^(-,

is

))

(42)

if5„_i >B;:_i,

(43)

— l,n =

where the stopping boundary B^ >

=

5„_i <B;:_i,

if

\

the two propositions below.

in

policy u'{f)

also reveal structural properties of the

and 5^_i

1,...,L,

= —1

indicates that wafer

not tested under any circumstances.

We

Proof.

only need to show that

a backward induction on

and consider the

n.

It

nonincreasing

V'„"'(5n) is

+

difference V^isn

1)

—

=

which

is

done by

+

1,

^ni^n)- In order to prove that this quantity

is

trivially true for

is

in Sn,

n

I.

Suppose

it

is

true for n

nonpositive, the following properties of the conditional density /(jn+i|5„) are required.

For n

=

1,

.

.

.

I —

,

1

and

>

.s„

there exists Xn+i

0,

>

such that

1

/(x„+i

-

1|5„

+

1)

>

/(j„+i|5„), for Xn+i

>

Xn+i, and

(44)

/(j^+i

-

l|.s„

+

1)

<

/(x„+i|5„), for Xn+i

<

x„+i.

(45)

These inequalities can be

verified using (38).

[(r(M - x„+i)

/

-CT-1 +

By

(40),

V;:+,{sn

+

it

1

+

suflfices to

consider the difference

X„+,)/(x„+i|.^„

+

l)(fx,+i]

Jo

/•CO

-

[{r{M

/

-

X„+i)

-

Cj

-

7

+

V;\i(5„

+

Xn+l)f{^n+l\^n)dXn+i]

Jo

=

+ na —

a

-+

Jo

1

K\i(5„+

1

+Xn + i)/(x„+i|s„+

l)(fXn + l

roo

Jo

roo

<

/

[KVl(^n

+

1

+

-C„+l)

- KT+JSn +

- /"[V„'Vi(5„+x„+i)-V;'Vi(5„ +

X„+i)]/(x„+i|5„

+

l)c?X„+i

x„+i)]/(x„+,|5„)(fx„+i.

(46)

Jo

Changing the integration variable

in

the

first

integral

20

from x„+i to x„+i + l and combining

the two integrals

/'

[Vn + liSn

-/

we

in (46),

+

[Vn'+l('Sn

-

^n+l)

+

-Tri

get

V;\

-

+ l)

5,

, (

+

^n''+l('^"

X„ + i )] [/(x„ +

+

- l|s„+

i

-

1)

/( X„+ ,

|.S

J](fx, +

,

(47)

•^n+l)]/(-rn + l|-«n)^-rn + l-

.'0

The two terms

inside the

hypothesis; hence, the

first

integral have opposite signs by (44)-(45)

integral

first

is

nonpositive.

because, by the induction assumption, V„\i(.s„

1

<

Xn+\- Therefore, (47)

The

and

is

is

The second

+ j-„^,) >

is

nonnegative

integral

is

+ x„+i

for

V'„\i(5„

nonpositive, and the induction

and the induction

)

<

verified.

|

following proposition establishes monotonicity of the optimal stopping boundary,

used to streamline the dynamic programming algorithm. The proof

the proof of Proposition

Proposition

6.

5,

and

is

similar to

is

omitted.

The optimal stopping boundary

satisfies

Bo<B]<...<B2_j.

variables.

In the numerical computations,

approximate the integrals by

amount

of computation.

finite

(48)

(39)-(41) involve L functions of continuous

The dynamic programming equations

the

<

Xn+\

we

summations.

discretize the continuous variables

Two observations

are helpful in reducing

boundary point can be

First, the final

and

explicitly derived,

and equals

^2-1 =

Also, since Ki(5„)

if

Sn

is

is

(a

+ (L-l)Q-l)(A/-(7 + CT)/r)/a-6.

nonincreasing

found such that K^l^n)

=

0,

in 5„,

is

then we set V;(x)

poUcy u'{f) cannot be optimal

number

the expected

Notice that the optimal boundary point 5o

=

calculate V^{sn) starting from 5„

we

=

for all

After the optimal solution u'(f) to the Lagrangian problem

determine N{u'{f)), which

(49)

= -1

for the original

or

0.

problem

If

21

is

derived,

we need

BJ = -1, then the

(4)-(6),

n

and

x € (sn,nM].

of wafers that are tested per

"

f{Sn-Sn-xK-^)..-f{si)dSn...ds„

Cn= /'.../

Js„=0

Jai=0

0,

Bq

lot.

screening

=

by

(11).

=

!,...,! -1,

If

to

0.

then

(50)

and the probability that

testing ceases after the nth wafer

=

Tn

where Co

=

1

C„_i

-Cn,

Then the expected number

•

N{n

n

= 1,...,I-

1.

of wafers tested per lot

(51)

is

= Y.^T^^L{\-Y^T^).

{-,))

n=l

We

is

(52)

n=l

conclude this section with an outline of the algorithm that solves the original

optimization problem (4)-(6).

Algorithm:

Step

1.

Step

2.

Let 7

=

and

=

set 7'

Find the optimal solution "'(7) to the Lagrangian problem (34) and the

optimal objective function value

stop.

The optimal

start rate

the optimal boundary Bq

and the optimal screening policy

Calculate N{u'{~i)) using (52), and define A^

Step

4.

Compute

(5,

is

the

where

maximum

6

is

=

is

—

—1, then

u'(7').

^itIN[u'{-i)).

the objective function value for the original problem,

over

= y[V\u{',)) +

7vV(u-(7))

a small step variable, and go to step

we could prove that P^

is

-

cf\.

(53)

P^'s calculated thus far, then let 7'

all

Notice that the algorithm

If

A^*

is

If

3.

If P-,

+

V~'{u'{~^)).

Step

P,

7

0.

concave

in 7,

7.

Change 7

to

2.

guaranteed to terminate, since Bq

is

=

= —\ when

7

— rM.

then a binary search, rather than an exhaustive

search, over 7 € [0,rM] could be employed, thereby saving a considerable

amount

of

indeed concave

computation. For

all five

with respect to

Although we have been able to prove that the optimal value function

V'^{u'{-^))

P-yl

is

7.

data

sets considered in the next section, P-,

is

decreasing and concave in 7, we have been unable to prove the concavity of

our obstacle

is

again the expression for N{u'{'^)) in (52).

22

5

Numerical Results

5.

we

In this section,

test

the optimal fixed sample size screening strategy and the

optimal sequential screening strategy on

10 lots

and each

lot

has

less

five sets of yield

than 25 wafers. The data

data, where each set has about

sets,

denoted by Cl,Cl -5,02.02.

and C3, were obtained by Bohn from the same factory producing the same product

five different

is

time periods. For each of the

used to obtain values of the

following procedure

maximum

is

gamma

(Qi,...,Qm).

followed for each data set.

on each wafer

in

on each wafer

maximum

b are

3^.

sets,

is

If

maximum

,3m) are

More

6.

likelihood parameter estimates a

to be the

(ai, ...,am); the profitability results for this case

lots,

then the

the median of

is

variable with

and

b.

known shape

(/^i, ..., Jrn)

are used

These parameter estimates

We

not reported here for reasons of confidentiality.

a

m

3m) by assuming that the number

(i3i

Finally, the revised estimates

identical estimation procedure, but chose

specifically, the

obtained from the number

estimate a by d, which

gamma random

a

likelihood estimation

a data set contains

{,3i

We

the set.

in lot k

parameter a and scale parameter

and

and

and then recompute the estimates

of defective chips

a. a

data

parameters a, a and

likelihood estimates (qi, ....q^)

of defective chips

to obtain

five

in

also

performed the

mean, rather than the median,

of

were quite similar to the results obtained

from the original procedure and are omitted.

As mentioned

earlier,

we assume

that

when the the probing

effective capacity

under the exhaustive testing

effective capacity.

The wafer

scrap rate

is

policy, the fab

facility

is

is

working

working at

its

90%

of

its

3%

of

at

5%, the variable probing cost per wafer

the variable fabrication cost per wafer and the revenue from a wafer containing

chips

is

is

all

good

10 times the wafer's variable production cost. These parameter values are based

on discussions with a variety

of

semiconductor managers and engineers, and are used to

derive the optimal fixed sample size strategy and the optimal sequential screening strategy

for

each of the

five

data

sets.

Both screening

policies vary little over the five

Figure 3 illustrates the two policies for data set Cl.

the optimal sequential screening policy

is

The stopping boundary

data

sets,

and

characterizing

nearly linear, but slightly convex, for every data

23

set,

and the slope increases with increased

the acceptable yield

size policy

is

in

the

lot.

)r

yield.

lot is

that the former only accepts lots of expected higher yield

<

a

o

O

<

fixed

sample

and requires a

it

is

not surprising

level.

Sequential

J

--

.^

.^

3500 -

-^

-^

STOP

3000 -

-^

-<

-^

z

o

required

considered acceptable

while the sequential screening strategy monitors yield continuously,

O 4000

is

than the optimal sequential policy. Since

the fixed sample size policy stops monitoring yield after a

c

3

determines

yield level over

The optimal

6 wafers from every lot in each data set,

slightly higher yield level to continue testing

4500

testing

The average acceptable

13.7% lower than the overall average

samples either

more

the lot-to-lot variability increases,

level, as

before discarding the remaining wafers

the five data sets

lot-to- lot variation. Since the slope

2500

-<

--

y

2000

.<

1500

CONTINUE

1000

^m^ffFixed Sample Size

500

5

Number

Cumulative

Figure

3.

Recall that the strategy

and to choose the

Optimal screening

commonly used

20

15

10

in

industry

Wafer

data

policies for

start rate so that the testing facility

24

of

is

25

set

Cl.

to perform exhaustive testing

works

at its effective capacity.

Before reporting our profit results,

is

it

increase that can be achieved relative to this straw strategy.

Let A^

denote the arrival rate under the exhaustive testing strategy, and

denote the average incoming

for

any strategy

yield.

let

(54,

the relative profit increase

is

X'-\^

__

A^

\^(V(u')-V{u^)\

\E\ V{u^)-cf

j

A^

\^\rL[\

MF-

^

A^

we assumed

effective capacity

that Lcj

=

0.0.3cf

.

-q)My-

Lcj - cf

- y]

+ A^ \rL{l - q)My - Lcj - Cf *'"

f

Lct(1

fiF

(

\E

'

rLAf = lOcf

,

q

=

0.0.5

and the fab

is

at

90%

of

its

under the exhaustive strategy, the upper bound equals

1

lO( OM{l-y) \

,

^''^

'^^--9^Y[ 9.5y-im )This quantity increases from 1/9 when yield

level of

— q)L

^.ltI{\

^

-V^

Then an upper bound on

X'{V{u')-CF)-XEiV{n^)-CF)

\^{V{u^)-cf)

Since

=

profit

M-

=

y

bound on the

useful to determine an upper

10.58% required

is

100%

for profitability in (11).

be revealed, the yield was greater than

36%

to oo as yield approaches the critical

Although the exact average

for all five

data

yield cannot

and hence AF^ax

sets,

is

between 11.1% and 12.0%.

Under the heading "Theoretical Calculations", Table

I

relative to the exhaustive testing strategy obtained by the

all five

data

sets.

We

also display

pF

=

^Ip^f and pj

the effective capacity utilization of the fab and testing

seen that for every data

set,

both

facilities

work

3%

increase

policies

is

is

two proposed strategies

= {\N(u)/ pj),

for

which represent

facility, respectively.

at their effective capacity.

profit increcLses are rather small: out of a potential

to

reports the profit increases

It

can be

However, the

11.1% to 12.0% increase, only a

2%

achieved. Also, the difference in performance between the two proposed

relatively small; the fixed

sample

size policy averages a

2.24%

over the five data sets, compared to 2.51% for the optimal strategy.

25

profit increase

Table

Data Set

1.

Numerical

results.

wafers tested per

start rates

were recorded.

lot

These quantities and the theoretically calculated

were then used to calculate the

profit increases that are reported in

Table

I

under the heading "Simulation Results".

When

occur.

yield

the yield model underestimates the

If

facility

the derived policies are tested on the actual data, two undesirable things can

number

of discarded wafers, then the testing

underutilized and a feasible, but suboptimal, strategy

is

model overestimates the number

overutilized,

and an

is

obtained.

If

the

of discarded wafers, then the testing facility

infeasible strategy can result.

Referring to Table

I,

we

is

see that the

yield

model correctly predicts the average number

of discarded wafers per lot under the

fixed

sample

sets,

sets

C2 and

data

size policy for three of the five

C2.5. However, the yield model

is

and

is

accurate under the sequential policy,

less

underestimating the average number of discarded wafers per

five

data

testing.

sets. In

Both

these cases, the resulting profit

policies overestimated the

the resulting strategy

is

number

is

feasibility.

was achieved by reducing the

and pr

sample

by .3-5%

less

in three of the

than under exhaustive

and

not feasible: hence, the profit increases reported for this data set

of 0.75 (0.90, respectively)

sets for the fixed

sometimes

lot

of discarded wafers in data set C2.5

correspond to a reduced start rate that maintains

(0.993, respectively)

by about 1% on data

off

—

1.000.

size strategy

That

is,

the profit increase

start rate so that

pf

=

0.991

The average

profit increase over the five

1.23%

simulation study, about

1% below

The

sequential

is

the corresponding improvement achieved

in

in the

the theoretical calculations.

data

strategy averages a 0.70% profit decrease relative to the straw strategy, because of the

underutilization of the testing facility in cases Cl.5 and C2. Hence, in addition to being

eaisier to

derive

and

to

implement than the sequential strategy, the fixed sample

size

strategy performs nearly as well in the analytical calculations, and appears to be more

robust in our limited simulation study.

As a point of

number

yield

of

model

reference,

we

also considered the beta-binomial yield model,

bad chips on each wafer

is

modeled

as a binomial

significantly overestimated the average

27

number

random

where the

This

variable.

of wafers tested per

lot:

the

average value over the

five

data sets of pT vinder the sequential strategy

in

the simulation

study was only 0.861, which led to an average profit decrease of 11.68%.

Acknowledgment

We

are deeply indebted to Roger Bohn,

research

is

who generously gave

supported by a grant from the Leaders

for

and National Science Foundation grant DDM-9057297.

28

us his yield data. This

Manufacturing Program

at

MIT

References

Albin, S.

and D.

J.

Friedman. 1989. The Impact of Clustered Defect Distribution

Management Science

Fabrication.

W. and

Atherton, R.

J.

in

IC

35, 1066-1078.

E. Dayhoff.

Introduction to Fab Graph Structures.

1985.

ECS

Abstracts.

Bohn, R.

1991.

E.

Noise and Learning

in

Semiconductor Manufacturing.

Center

for

Technology Policy and Industrial Development, MIT, Cambridge, M.A.

Chen, H, M.,

J.

Harrison, A.

Mandelbaum, A. van

.Ackere,

and

L.

M.

VVein.

1988.

Empirical Evaluation of a Queueing Network Model for Semiconductor Wafer Fabrication.

Operations Research 36, 202-215.

Cunningham,

J. .A.

Manufacturing.

1990.

IEEE

The Use and Evaluation

of Yield

Variations in Semiconductor Wafers.

IEEE

M. G. C. Resende.

Circuit Manufacturing.

Goldratt, E. M. and

IEEE

Circuits

1988.

J.

K. Paulsen. 1987. Radial Yield

and Devices Magazine, March,

Closed-Loop Release Control

Trans, on Semiconductor Manufacturing

Cox. 1984. The Goal North River Press,

J.

in Integrated Circuit

Trans, on Semiconductor Manufacturing 3, 60-72.

Ferris-Prabhu, A. V., L. D. Smith, H. A. Bonges, and

Glassey, R. C. and

Models

Inc.,

1,

for

42-47.

VLSI

36-46.

Croton-on-Hudson,

NY.

Longtin, M., L.

Manufacturing,

Cambridge,

M. Wein, and

II:

R. E. Welsch. 1992. Sequential Screening in Semiconductor

Exploiting Spatial Dependence. Sloan School of Management. MIT,

MA.

Mallory, C. L., D. S. Perloff, T. F. Hasan, and R. N. Stanley. 1983. Spatial Yield Analysis

in Integrated Circuit

Manufacturing. Solid State Technology, November, 121-127.

29

Osburn, C. M., H. Berger. R.

P.

Donovan, and G. W. Jones.

1988.

The

Effects of

Contaniination on Semiconductor Manufacturing Yield. The Journal of Environmenta!

Sciences, March/.A.pril, 45-57.

VVein, L.

M.

1988. Scheduling Semiconductor Wafer Fabrication.

conductor Manufacturing

1,

115-130.

30

IEEE

Trans, on Senai-

Date Due

AU8.

S

t

llf

Lib-26-67

MIT LIBRARIES DUPl

3

TDflD

007nMMfl

D