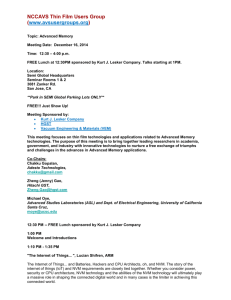

Mechanism and Assessment of Spin Transfer Torque (STT) Based Memory by

advertisement