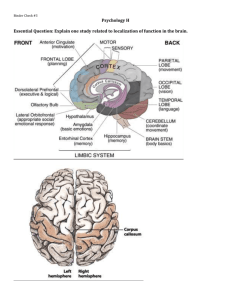

CONSTRAINED AND UNCONSTRAINED LOCALIZATION

advertisement