a GAO DEFENSE ACQUISITIONS

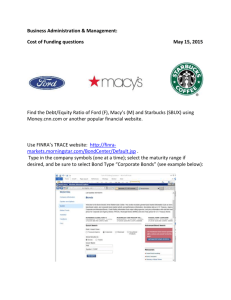

advertisement