GAO GROUNDWATER CONTAMINATION DOD Uses and

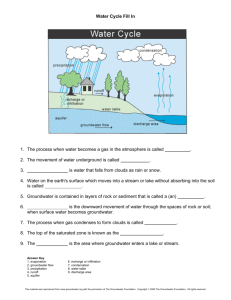

advertisement