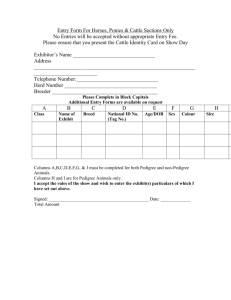

Beef Cattle Day Room . ,),›cltatetozv of Thirteenth Annual

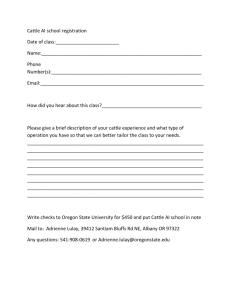

advertisement