Apples and Pears u th4 #ood aüLe4 Va2, Coal oj P'sodce#tq

advertisement

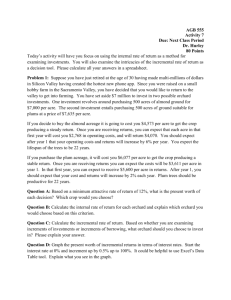

Coal oj P'sodce#tq Apples and Pears u th4 #ood aüLe4 Va2, e9O# PROGRESS REPORT ill Gustav W. Kuhiman Arthur E. irish Agricultural Experiment Station Oregon State College Corvallis Circular oF Information 486 June 1950 Coal oj P4odAcüy Apples and Pears us Ihe hood Ruie, Va, (e9o#s PROGRESS REPORT Ill Gustav W. Kuhiman, Agricultural Economist Arthur E. Irish, Fieldman This report is a summary of detailed cost records kept on 21 fruit farms in the Hood River Valley for the year 19149 with comparable data for 19147 and 19143. The cost of production includes all items of expense incurred in producing and delivering the crop to the door of the packing house or processing plant. Nb packing house costs are included. Apple Production Costs The cost of producing apples in 19149 on 20 orchards averaged 78 per loose box and 31.214 per packed-box basis, exclusive of packing and storage costs (Table 1). Assuming packing and handling charges (from l.25 to $1.50) the total F.0.B. cost would be 2.142 or more per packed box. Cost of Production, Hood River Valley, Oregon, 19147-19149. Table 1. APPLES: (Does not include cost of storage, boxes, packing, and shipping) Item Year Year Year 19147 19148 19149 3-year average Percentage oi' average 25 20 16.2 572 353 16.2 563 360 Cents 33.1 Picking ............................12.5 Other harvest ...................... 6.9 52.5 Total labor 13.3 Materials 11.6 General expense 6.2 Depreciation on equipment Interest on investment (5 per cent) 9.5 Cents 29.1 12.5 5.7 Cents 147.3 33.8 12.2 12.3 5.7 8.7 146.2 53.5 12.0 12.9 6.0 9.0 12.6 114.6 12.14 114.14 6.0 9.1 10.5 Total cost per loose box ......... 93.6 37.2 78.2 36.3 100.0 Number of orchards in study .......... Acreage of apples per orchard ........15.2 214 Yield per acre, loose boxes 5142 Yield per acre, packed boxes .........323 Costs per loose box for: Preharvest labor 214.2 9.5 5.1 561 3149 Cents 23.3 11.5 5.9 Per cent 33.14 13.3 6.3 7.0 139.1 123.5 139.14 Cost per packed-box basis* 1514.14 * Growers received about 432 per ton (equivalent to 20 cents return per packed box grown) for the low-grade apples taken to the cannery. The cost per box of apples produced in 19149 was about 10 per cent less than in 19148 with approximately the same yield per acre. See Table 2 for the labor requirements by operations and the itemized costs per acre for the apple orchards studied. 1/ Fruit growers, processors, and the Hood River Branch Experiment Station requested the Oregon Agricultural Experiment Station to conduct a cost project on representative orchards in the The cooperating growers Hood River Valley. Arthur E. Irish of Hood River served as fieldinan. kept daily records on their respective enterprises. 2 Table 2. APPLE PRODUCTION COSTS, Rood River Valley, Oregon, 19147-19149. (Does not include cost of storage, boxes, packing, and shipping) Man hours Cost I l9L Item 19147 19147 l9145 19149 Labor per acre Pruning . 31.6 39.2 33.1 $ 29.71 $ 38.96 5.2 5.63 Brush removal . 6.8 6.72 5.8 2.6 1.1 Rand cultivating 2.27 3.18 3.5 Machine cultivating ... 14.21 14.6 14.0 14.1 14.147 2.14 2.29 Fertilizing; mowing ... 1.7 1.58 1.5 11.2 20.0 11.2 Irrigating .... 11.67 19.35 11.2 18.6 Spraying 17.62 15.70 15.3 143.02 Thinning 30.14 37.15 143.14 149.5 8.81 6.149 Propping 9.6 14.8 6.5 22.10 20.8 25.0 31.07 Maintenance ..... 31.7 12.6 21.26 12.92 Supervision ...... .... 8.7 15.7 $166.55 186.0 Total preharvest .... 167.0 179.63 1140.14 67.52 67.7 71.140 Picking i9.3 79.14 36.6 30.3 27.8 37.16 32.148 Other harvest 235.9 $2814.31 $270.143 256.6 Total labor .......... 302.0 Materials per acre Fertilizers ..............................................$ 114.03 5.53 Irrigation water 147.62 Sprays 7.83 Miscellaneoussupplies.. ........................... Totalmaterials ........................................$75.01 General expense per acre Building repair $ 14.79 Machinery repair . ............................... 9.09 Machinehire 3.014 Gas and oil Electricity; water; wood fuel; office Liability, fire, and motor insurance 9.1.10 7.25 6.37 12.85 Propertytaxes Cash to operate .......................................... 10.00 Total general expense .............................. .... Depreciation per acre Buildings (not including operator's dwelling) $ 12.67 20.83 Machinery Total depreciation ..................................... $ 33.50 Interest per acre (5 per cent) Buildings ..s.....I.ø ....... $ 9.67 11.03 Machinery ....... . . . . . . . ............ . ............ . ....... 30.69 Orchard ................................................. Total intere st .............. . . . ................ . . . . . . . $ 51 39 $507.00 Total cost per acre ......................................... Cost per loose box ......................................... .914 $ .. Cost per packed box* $ 1.514 Acres per orchard ... .......................... ..... ...... 15.2 Loose boxes produced per acre ..... ............... . ..... 5142 Packed boxes produced per acre . ..... .. ...... 328 $ 114.61 5.20 39.17 9.61 $68.59 $ 2.98 10.00 3.28 12.09 19149 8 31.52 14.60 .87 14.00 1.61 11.12 11.145 26.68 14.148 26.05 114.83 $137.21 514.13 28.91 $ 11.56 6.11 141.65 9.98 $69.30 $ 3.32 8.16 6.90 11.61 8.146 8.147 10.714 7.01 16.29 10.00 $ 73.85 17.140 $ 12.32 22.38 $ 314.70 $ 9.36 11.55 30.59 51.50 $1499.07 .87 $ $ 1.39 16.2 10.00 $ 72.86 $ 10.27 21.86 $ 32.13 $ 8.5Li. 10.22 30.61 $ 1.1.9 67 $141414.26 $ $ .78 1.214 16.2 568 360 355 *Orowers received about $32 per ton (equivalent to 20 cents return per packed box grown) for the low-grade apples taken to the cannery. 572 3 Pear Production Costs Winter pears The cost of producing winter pears in 19149 on 21 orchards averaged 96 per lug box and .31.10 per packed-box basis, exclusive of packing and storage costs (Table 3). Assuming packing and handling charges (from l.25 to $1.50) the total F.OB. cost would be $2.35 or more per packed bcc. Table 3. WINTER FEARS: Cost of Production, Hood River Valley, Oregon, 19147-19149. (Does not include cost of storage. boxes. ackin. and shiDpin') Item Number of orchards in the study Acreage of winter pears per orchard Yield per acre, loose lug boxes Year Year Year 19147 19148 19149 214 214 21 11.8 398 363 10.9 388 386 Cents 13.3 5.9 Cents 26.0 9.8 6.3 Cents 29.0 11.7 6.3 148.6 142.1 147.0 146.0 15.5 16.3 17.0 8.3 13.2 96.1 16.14 7.8 13.8 101.2 19.6 17.7 9.0 15.8 109.7 15.9 16.0 8.1 114.3 114.0 102.3 100.0 1114.3 120.3 109.9 1114.8 1459 Costs per loose lug box for: Preharvest labor Picking Cents 3L14 12.1 Other harvest ........................ 6.8 Total labor ........................50.3 Materials ............................ 114.3 Cost per packed-box basis Percentage of average 10.7 Yield per acre, packed boxes ...........1406 General exiense Depreciation on equipment Interest on investment (5 per cent) Total cost per loose lug box 3-year average 114.5 29.14 141414 14314 8.3 Per cent 11.14 6.2 A 10 per cent increase in yield for 19149 over 19148 was accompanied by a 9 per cent decrease See Table 5 for the labor requirein cost per lug box and per packed-box basis, respectively. ments by operations and the itemized costs per acre for the winter pear orchards studied. Bartlett (cannery) pears The cost of producing cannery pears in 19149 on 20 orchards averaged 31.214 per lug box and See Table 6 for itemized costs. 353.1414 per ton (Table 14). Table 14. BARTLETT (CANNERY) PEARS: Cost of Production, Hood River Valley, Oregon, 19147-19149. (Includes all costs, delivered to the cannery door) Item Number of orchards in the study Acreage bearing pears per orchard Yield per acre, loose lug boxes Year Year Year 19147 19148 19149 23 214 20 14.7 5.2 258 5.2 5.9 363 295 8.14 6.7 Dollars Dollars Dollars 263 Yield per acre, tons ................... 5.3 Costs per loose lug box for: Preharvest labor Picking Dollars .60 .11 ........................ .08 Other harvest Total labor .........................79 Materials General expense Depreciation on equipment Interest on investment (5 per cent) Total cost per loose lug box Cost per ton 3-year average .26 .26 .12 .21 Percentage of average Per cent .12 .08 .09 .06 .52 .11 .07 .71 .28 .28 .60 .70 146.14 .214 .25 .12 .20 15.9 16.6 7.9 13.2 100.0 .145 .23 .18 .20 .10 .16 1.614 1.614 1.214 1.51 $714.60 $72.31 $53.hh $66.78 .114 314.5 7.3 14.6 Table 5. WINTER PEAR PRO1JCTION COSTS (Does not include cost of storage, Hood River Valley, 19147-19149. boxes1 packing. and shipping) Man hours Item Labor per acre Pruning .. ..... . Cost 19117 l91&8 19149 1j9.9 1414.6 143.1 1.16.00 $ 142.77 $ 113.11 14.6 14.1 14.60 14.143 3.89 2.3 2.7 2.18 1.8 9.8 12.7 1.6 3.2 1.2 10.6 8.7 1.99 2.82 1.90 .1 -- Brush removal ......... 14.9 Hand cultivating ...... 2.5 Machine cultivating ... 3.6 Fertilizing; mowing ... 2.2 Irrigating ..... ........ 114.5 Spraying 114.1 Thinning . . 1.8 Propping . .......... ... 6.8 Maintenance 25.0 Supervision . ......... . 20.1 Total preharvest .... 145.11 Picking 61.i.5 Other harvest ......... 31.14 Total labor . ......... 2141.6 Materials per acre $ 3e140 2.02 9.714 5.143 3.21 21.27 13.66 $117.06 214.147 5.9 3.6 22.9 214.60 8.6 113.5 66.0 22.7 202.2 12.3 111.3 $1144.27 Fertilizers . ........ . ........ .............. ........ Irrigation water ....................................... rays . ............ . .................................... Miecellaneoussupplies..... ........ .......... .......... Total materials ...... ........ ....... ........ General expense per acre Building repair ............ ............ ......... I Machinery repair chine hire ............................................ Gas and oil ............... ...... E1ectricitr; water; wood fuel; office Liability, fire, and motor insurance 26.61 55.36 31.33 $230.96 $114.39 5.75 37.44 . . . . Totalinterest ........................................ Totalcostperacre Cost per loose box Costperpackedbox Acres per orchard .. .... . Loose lug boxes produced per acre ........................ Packed boxes produced per acre ............................. - 9.148 .06 52.914 23.140 114.80 115.149 143.75 $193.40 27.90 $157.17 $16.10 $11.67 5.52 11.87 6.31 37.10 13.85 167.52 $ 714.214 $65.93 $ $ 2.50 140.75 10.214 14.67 11. 13 1.86 11.07 6.82 7.60 Propertytaxes 13.30 Cash to operate ............................................10.00 Total general expense ................................. $ 66.45 Depreciation per acre Buildings (not including operator's dwelling) . ......... $ 13.63 Machinery 22.02 Total depreciation ............................. . ....... $35.65 Interest per acre (5 per cent) Bi1gs ...... .......... . ...... .. ........... $ 10.06 Machinery . . . . . . . ...... . .............. . . . . . . . . . . . . ....... 11113 Orchard . . . . . . . ........ . . . . . . .............. ...... . 1.314 3.29 1.21 10.69 12.99 20.14 27.0 193.0 19119 114.09 12.99 1.58 6.20 514.7 19148 19147 $ 2.80 8. 75 9. 53 3.15 12.80 8.69 7.87 6.26 12.00 9.16 8.00 17.59 10.00 $ 75.34 16.514 10.00 $ 70.30 $ 12.81 23.26 $ 11.22 $36.07 $36.76 25.514 142.37 141.17 9.12 11 29 38.06 $63.56 $62.55 $55.47 114614.144 $436.59 $ 1.10 $ 1.20 11.5 398 363 $1426.67 .96 $ $ 1.01 $ 1.114 10.7 1459 1406 $ 9.81 11 90 $ $ 1.10 10.9 14414 388 S Table 6. BARTLETT PEAR PRODUCTION COSTS: Hood River Valley, Oregon, l9LL7-l9l9. (Includes all costs delivered to the cannery door) Man hours I Item Cost I 19147 19145 19149 23.5 37.0 142.2 $ 22.00 $ 36.95 14.2 14.8 3.14 14.12 14.514 14.9 14.0 3.7 14.33 3.71 $ 142.55 3.22 3.22 3.14 14.2 3.50 1.73 3.145 14.214 ]J4.9 3.3 1.3 7.8 1.32 7.91 16.2 114.0 143.3 27.8 5.1 21.3 5.9 l.Ll 12.53 9.78 38.89 Labor per acre Pruning Brush removal Hand cultivating . Machine cultivating .... Fertilizing; mowing .... Irrigating Spraying .............. . Thinning Propping ............. .. Maintenance Supervision Total preharvest ..... 11.6 25.1 15.8 165.1 Picking ...... ........ .. 314.1. 1.8 19147 1.14 12.14 19149 19145 9.1 114.57 114.85 114.38 1414.1 37.12 214.141 5.0 26.1 9.9 161.5 10.214 214.89 14.65 23.114 19.72 $157.07 29.15 20.37 $206.62 8.23 5132.69 31.03 20.05 $153.77 28.85 12.31 *161.92 33.00 22.79 $217.71 3 12.07 5.01 $ 16. 71.i. $ 11.149 5.25 Miscellaneous supplies ....................................10.06 141.55 10.143 5.65 36.31 11.79 69.33 3 73.97 3 65.214 Other harvest ........... 21.2 Total labor ....... ... _ 220.14 132.3 35.7 20.0 191.0 Li.l.2 21.5 2214.2 14.92 Materials per acre Fei1izers ........... Irrigation water Sprays ................ 142.19 Total materials General expense per acre Building repair Machinery repair chine hire Gas and oil Electricity; water; wood fuel; office .......... Liability, fire, and motor insurance Property taxes .......................................... Cashtooperate 3 14.51 $ 10.23 2.88 lO.Li.7 7.73 10.19 12.63 ..........................................10.00 Total general expense ...................................3 68.614 Depreciation per acre Buildings (not including operator's dwelling) ......... 3 12.12 20.80 Machinery ............................................... 2.79 9.82 2.80 12.30 9.15 3 2.50 7.25 10.38 9.11 7.914 8.214 16.59 10.00 * 71.39 17.58 10.00 $ 73.147 $ 12.23 $ 9.52 22.79 21i.146 $35.02 $33.95 3 $ 514.67 9.72 12.02 37.31 $ 59.05 Totalcostperacre $1432.15 $1423.20 $14WJ.I4 Cost per loose-lug box Cost per ton $ 1.614 3 714.60 3 1.614 $ 72.31 5.2 S.9 258 $ $ $32.92 Totaldepreciation Interest per acre (5 per cent) Bldings ............................................... Orchard Total interest 9.514 31i..16 Acres per orchard ............................. Tonsproducedperacre ...................................... Loose boxes produced per acre 3 10.97 Machinery . . .............................. 14.7 5.8 263 3 9.01 12.37 36.66 $ 55.014 1.214 53.1414 5.9 8.14 363 Age of the Trees The orchards typically have trees of varying ages ranging from a year up to maturity (Table 7). The usual practice followed by most growers is to replace any dead or undesirable trees and thus tend to perpetuate the orchards. Therefore, depreciation on orchard investment was not included in computing the cost of producing fruit. Table 7. AGE OF TREES: Distribution on 21 Farms Studied, Hood River Valley, Oregon, l9L9. Age of trees Apples Winter pears Per cent Per cent Less than 6 years 6 to 9 years 10 to lt years 12 11 6 71 100 12 8 10 lL years and over ...............70 All trees 100 .................. . W j 114.0 U LLk) UI. US C0 flflQ 11') U SILLS. 12U.CLL LIZ Bartlett pears Total Bearinga Per cent Per cent 27 31 0 10 3L Lh 100 100 LI.JILI}JIA USL% LU 01 .15 p4. J'J.L¼. U3.J&Z IJOUWOC JLJC LI%JILIJCS .1.115 trees comprised an abnormally high proportion of the total Bartlett pear plantings on the farms studied. About four-fifths of the apple trees were 10 years old or over. Over three-fourths of the In the case of the Bartlett pears only Ii.2 per cent of winter pear trees were 10 years or older. the trees had come into full bearing. One-third of the trees were just beginning to produce, In order to make while more than one-fourth were less than 6 years old when this study began. the three orchard enterprises studied more nearly comparable, the latter group of trees (less than six years old) was excluded in computing cost of production. Thus 16 per cent of the Bartlett pear trees covered in the cost study were less than full bearing age (under 10 years), and L per cent of the trees were in full bearing. Varieties Newtown and Delicious (Red, Striped, and Golden) comprised the major portion of the apple D'Anjou is the principal winter (storage) pear, and acreages on the farms studied (Table 8). the Bartlett is the canning pear. Table 8. VARIETIES OF TREES: Distribution on 21 Farms Studied, Hood River Valley, Oregon, l919. Winter pears on farms studied Apples on farms studied Variety Newtown Delicious Variety Percentage 314 D'Anjou ......... Bosc ................... Easter Ortley ...... . ...... ... 5 Spitzenherg ............ 14 Cornice Other .................. 14 Other Total 100 Total Percentage 86 10 2 1 1 100 7 Orchard Invesfmenf The capital value represented by the plantings was estimated by the growers from a conConsideration was given in the appraisal to the age and variety servative, long-term standpoint. of trees and to the location and character of the land. The present (depreciated) values of buildings (other than operator's dwelling) and all dther equipment were allocated proportionately to the various enterprises according to the use made thereof (Table 9). Table 9. ORCHARD INVESTM!NT: Average Value of Capital Investment on 21 Farms Studied, Hood River Valley, Oregon, l9L9* Item Orchard Value per orchard 3 9,907 $ Buildings ...............2,86 $ 612 Bartlett pears Winter pears Apples Value Value per per acre orchard 8,262 3 Value per acre Value per orchard 761 3 14,3L7 Value per acre $ 733 177 1,976 182 1,067 130 3,302 2Ot 2,I451 226 l,I71 21L8 3,238 200 2,171 200 1,186 200 $]J,863 319,312 $1,193 Total investment ..... * See Table 10 for acreages per orchard studied. $1,369 8,071 31,361 uipment Cash for operating .. $ Apple enterprise The estimated werth of the capital, represented by the apple enterprise on the 21 farms in the study, averaged $19,312 per orchard. Nearly half of the total capital investment for apple production, or $612 per acre, was for the plantings. Buildings (exclusive of the operator's dwelling) averaged $2, 86 per apple orchard. The equipment inventory, averaging 33,302 per apple orchard, includes irrigation equipment as well It does not include the automobile (charge as the machinery, tractors, trucks, and small tools. for the uSe of automobiles was computed on a mileage basis). Winter pears The investment for winter pears averaged $]J.i,863 per orchard. The value of the plantings averaged 38,262 per orchard or $761 per acre. The investment in buildings and equipment per acre of pears was similar in amount to that shown for apple orchards In this study. Bartlett (canning pears) The investment for bearing Bartlett pears averaged $L,317 each or $733 per acre. 5,07l per orchard. Plantings represented Land Use The size of the 21 farms in the study averaged 57 acres per farm (Table 10). Orchard plantings comprised 35.14 acres per farm. This was 814 per cent of the total cropland or 62 per cent of the total farm acreage. The remainder of the cropland was chiefly in hay or used as pasture. Much of the untillable acreage is steep, rocky, and covered with trees nd brush. Table 10. Utilization of the Land on 21 Farms Studied,* Hood River Valley. Orecon. 1919. FRUIT FAR1.S: Number Land Use of farms 20 21 21 Other ...................13 21 Total orchard Apples 3artlett pears Winter pears Acreage per farm reporting Acres 16.2 Average acreage per farm Acres 15.14 Percentage of total farm area Per cent 27.0 7.6 7.6 13.14 10.9 10.9 19.1 2.6 2.5 1.5 --35.14 62.1 Other cropland 11 3.5 14.14 7.7 21 2.2 Farinstead 2.2 3.9 Nontillable 16.6 26.3 19 15.0 --57.0 Total. ................ 21 100.0 acres in orcnaru, appie trees occupieu i).!4 acres per jarm. roai. pear winter ne .z ui and canning) acreage slightly exceeded the apple orchards with 13.5 acres per farm. Thirteen of the 21 growers in the study had cherry olantings. These averaged 2.5 acres per farm reporting cherries. Purpose and Nature of the Study The purpose of this study was to obtain information from growers that would provide basic facts on yields and on costs of production. This information, when carefully adjusted to reflect changes occurring in yields and in the price level of farm production cost, provides a basis whereby cost of production can be readily estimated for any given year if no changes have occurred in production techniques. The cost of production reported herein is the average-acre cost of the entire plantings in the study. Thus, the man-hours-per-acre (See Tables 2, 5, 6) is a figure that is applicable to the entire acreage of a crop within an area such as a county and indicates the average amount of labor that may be required per acre for all of the acreage in that crop in the area even though each acre nay not have been covered by each operation. The same holds true of the other items of cost. Acknowledgments The authors gratefully acknowledge the fine cooperation received froffi the 21 growers who kept detailed daily records which provided the data for this report. Special mention is made of the financial assistance contributed by the Hood River Traffic Association. Without the active participation of both these groups, the study would have been impossible. Leroy Childs, Superintendent of the Hood River 'Branch Experiment Station, Paul C. Newkom, Apple Growers Association, Robert Nunamaker, fruit grower, and A. L. Marble, formerly County Agricultural Agent of Hood River County, were instrumental in helping to plan and initiate this project.