Document 11045694

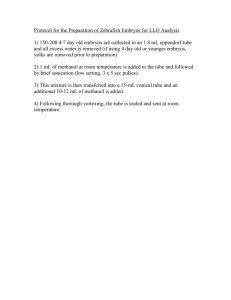

advertisement