-«r J

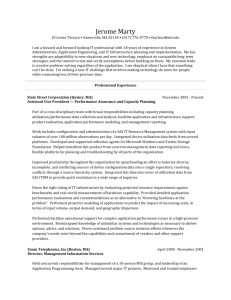

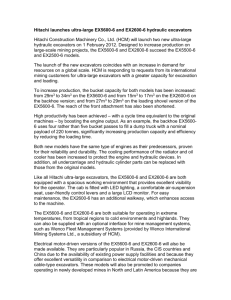

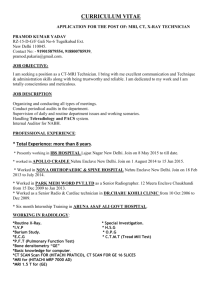

advertisement