A CONTROL THEORIST'S PERSPECTIVE ON ... TRENDS IN MANUFACTURING SYSTEMS

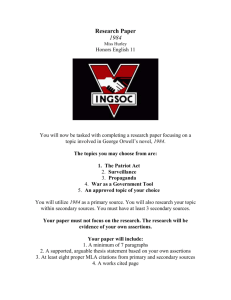

advertisement