Document 11040501

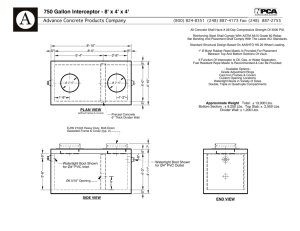

advertisement