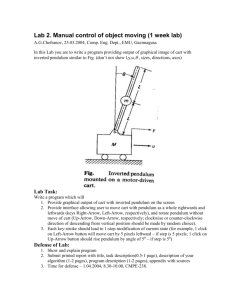

Stabilizing the Dual Inverted Pendulum: A Practical Approach Taylor Wallis Barton

advertisement