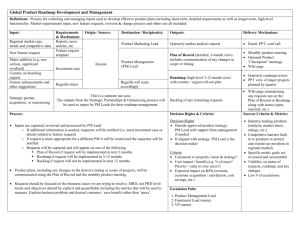

Reducing Instability In A Transforming Organization

advertisement