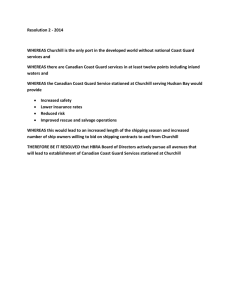

organizational change in the Coast & Analysis

advertisement