LEAN TECHNOLOGY DEVELOPMENT by Salim Bouzekouk Ing6nieur Polytechnicien, 1998

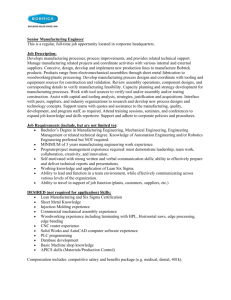

advertisement