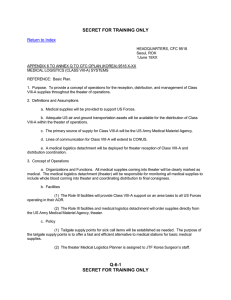

Distribution Operations Joint Publication 4-09 05 February 2010

advertisement