Document 11013433

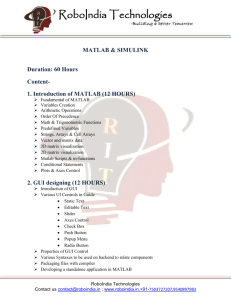

advertisement