Document 11012863

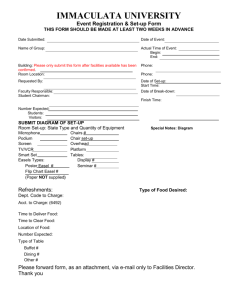

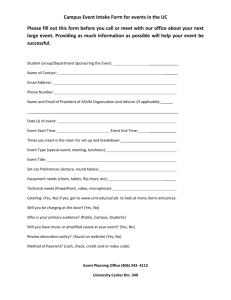

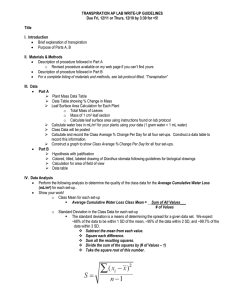

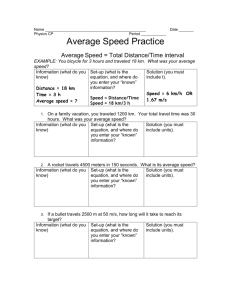

advertisement