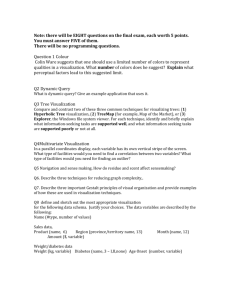

An Approach to Strategic Capacity Planning Using by

advertisement