Document 10983481

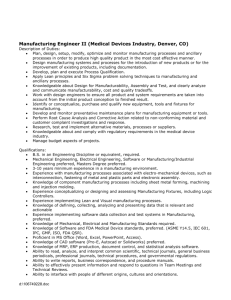

advertisement