Document 10981474

advertisement

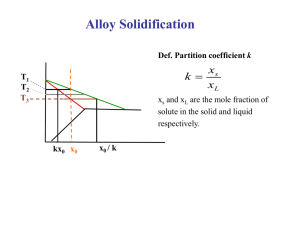

INTERFACIAL PARTITIONING DURING SOLIDIFICATION

by

JAMES C. BAKER

B.S.

Michigan State University

(1965)

M.S.

Michigan State University

(1966)

Submitted

in Partial Fulfillment of the

Requirements

for the Degree of

DOCTOR OF PHILOSOPHY

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June, 1970

Signature of Author

Dep-tment of Metallurgy

May 14, 1970

af

Certified by

·Thesis Supervisor

.'

~ ~<

Accepted by

Chairman, DepartmentalY

Committee

on

Graduate Students

Archives

JUN

8

970

ii

INTERFACIAL PARTITIONING DURING SOLIDIFICATION

By

James C. Baker

Submitted to the Department of Metallurgy and Materials

May 14, 1970, in partial fulfillment of the requirement

degree of Doctor of Philosophy.

Science on

for the

ABSTRACT

It has been demonstrated experimentally that departures

from local equilibrium at the interface do occur during rapid

solidification of zinc-cadmium alloys.

The resulting solid

compositions are larger than the equilibrium solid compositions at

any temperature, including metastable equilibrium compositions

below the eutectic.

This implies the solute chemical potential

increases during the freezing process.

Non-equilibrium alloy

solidification theories of Jackson, Borisov, and Baralis cannot

predict an increase in solute chemical potential, and therefore are

invalid.

There is a group of theories that do predict an increase

in chemical potential during freezing.

This set of theories as

well as the above set can both be derived from irreversible

thermodynamics.

The two types of theories can best be understood

in the common framework of irreversible thermodynamics.

Within this

common framework contradictory predictions can be made from

theories starting with identical assumptions. Therefore, the

validity

of both groups of theories is in doubt, and irreversible

thermodynamics as currently applied is untrustworthy.

A kinetic theory is developed which indicates that if

solute atoms are adsorbed on the liquid-solid interface then their

chemical potential increases during the solidification process,

even at low interface velocities.

Thesis Supervisor:

John W. Cahn

Title: Professor of Physical Metallurgy

TABLE OF CONTENTS

Section

Page

Number

Number

ABSTRACT

ii

LIST OF ILLUSTRATIONS

iii

ACKNOWLEDGEMENT

GENERAL INTRODUCTION

1

1.

Introduction

1

2.

Continuous Interface Motion in Pure

Materials

2

3.

III

Equilibrium

Segregation at Phase

Boundaries

5

Driving Force for Interface Motion

in Binary Alloys

9

5.

Continuous Interface Motion in

Binary Alloys

16

6.

Scope and Objective

4.

II

vi

S

of Thesis

SOLUTE TRAPPING BY RAPID SOLIDIFICATION

20

31

1.

Introduction

31

2.

Experimental

33

3.

Discussion

34

4.

Appendix

40

THERMODYNAMIC ASPECTS OF SOLIDIFICATION

PROBLEMS

50

50

1.

Introduction

2.

The Assumption

of Local Equilibrium

54

3.

Steady-State Binary Solidification

56

Section

Number

IV

Page

Number

IRREVERSIBLE THERMODYNAMICS OF INTERFACE

PROCESSES

65

1.

Introduction

65

2.

General

65

3.

Solidification

4.

V

VI

Principles

Theories

73

A.

Borisov Theory

73

B.

C.

D.

E.

Jackson Theory

Baralis Theory

Aptekar-Kamenetskaya Theory

Jindal-Tiller Theory

74

75

76

77

Discussion

of Theories

78

AN ALTERNATE APPROACH TO INTERFACE

PARTITIONING DURING SOLIDIFICATION

81

1.

Introduction

81

2.

Diffusional

3.

Graphical

4.

Appendix

Solution

Representation

81

85

90

SUMMARY AND GENERAL CONCLUSION

100

1.

Summary

100

2.

Suggestions

3.

References

103

4.

Biographical Note

106

for Future Work

101

iii

LIST OF ILLUSTRATIONS

Figure

Number

I-1

Page

Number

Graphical method for obtaining the chemical

potentials from the molar free energy

curve.

I-2

Graphical

23

construction

for obtaining the

equilibrium chemical potentials and

compositions from the free energy curves

I-3

I-4

for a binary system.

24

Graphical method for obtaining the total

free energy change of

when a mole of

material of composition C is added to a

large amount of

at composition C.

25

Graphical

illustration

of free energy AG

per mole reacted for diffusionless

reactions

I-5

I-6

I-7

of composition C

from a to S.

26

When the ratios of the reacting components

coincides with those of one of the phase,

the general tangent-to-tangent rule for

obtaining free energy changes reduces to a

tangent-to-curve rule. Here Cr = C .

27

It is thermodynamically possible to form

solid of any composition between C s ( l) to

C s (2) from liquid of composition C.

28

The domain of all possible solid compositions that can form from various liquid

compositions

at a given temperature is

enclosed within the curve OABEP.

curves OE and EP represent

The

conditions of

equal chemical potential for solute and

solvent respectively. They are straight

lines for dilute solutions.

Their inter-,

section E is the equilibrium condition.

The line OB is for a diffusionless transformation, with B representing the T

condition.

I-8

o

Schematic free energy curves to illustrate

the evolution of the curve OABEP of

Figure I-7.

29

30

iv

Figure

Page

Number

Number

II-1

Portion of phase diagram showing

equilibrium

composition of solid and

liquid.

11-2

44

Portion of eutectic

phase diagram

illustrating equilibrium metastability

of solid and liquid.

45

II-3

Zinc-cadmium retrograde phase diagram.

46

II-4

Plot of unit cell volume of zinc-rich

solid at -196°C against weight per cent

cadmium of initial liquid.

47

II-5

Electron micrograph of Zn-3.5 w/o Cd

which was splat quenched to -196°C.

130,000X.

II-6

48

Electron micrograph

of replica of

Zn-3.5 w/o Cd which was cooled by the

piston and anvil technique.

8,000X.

III-1

49

When there is a spinodal in the miscibility

gap the stable-metastable phase diagram

lines end when the solidus meets the

spinodal. Further extensions of the

metastable liquidus and solidus line are

unstable and intersect at a point on the

T

III-2

0o

line.

62

The domain of possible

liquid interface

compositions for steady-state solidification of an alloy of composition C

at

three different temperatures. At steadystate Cs equals C.

As indicated b the

arrows upward fluctuations is solid composition reduce the solute content of the

liquid and downward fluctuations increase

it. Steady-state cannot be established

by a system at point F in temperature

region II.

maintained

Local equilibrium cannot be

in region III.

63

V

Figure

Number

III-3

IV-1

Page

Number

Liquidus, solidus and T o curves defining

the three regions of temperature of

Figure III-2.

64

In the double primed set the free energy

change per mole of solid formed AG is

apportioned among a solidification

reaction AGs for which the driving force

is A averaged among the atoms in the

liquid at the interface and a redistribu-

tion reaction in which the differences in

Ap act to bring about the composition

difference

V-1

(CL - C ).

L s

80

Graphical illustration of the interdiffusion coefficient D(x) and the solute

interaction energy E(x) as a function of

distance x through the interface.

The

value of the solute interaction energy at

V-2

the center of the boundary EB will be

allowed to vary from EB << EL to EB >> E S

in the analysis.

90

Partitioning at interface

of imposed growth rate.

91

as a function

-vi

ACKNOWLEDGEMENTS

The author wishes to express his sincere thanks

to Professor John W. Cahn for his peerless guidance

and continued encouragement throughout this investigation.

Helpful discussions with Professors K. C. Russell

and M. C. Flemings are greatly appreciated. Thanks is

also due to Dr. B. C. Giessen for his contribution of

time and splat cooling equipment.

Special thanks are due to Mrs. Janine Weins for

her assistance

in the electron microscopy

portion of the

study, and Dr. Ronald Heady for computer programming

assistance.

The author is deeply indebted to his wife, Bonnie,

for colossal patience and understanding throughout the

course of the work.

The financial support of the National Science

Foundation is gratefully appreciated.

1

Chapter

I

GENERAL INTRODUCTION

1.1

Introduction

The purpose of this chapter is to give the reader

the necessary background

and a framework for understanding

succeeding chapters. Consequently, a number of distinct

concepts need mentioning, and for this reason the various

sections of this chapter may appear to be somewhat

unrelated.

An attempt will be made throughout the chapter to

show that the same principles

which apply to interface

motion in solids, such as during recrystallization,

can be

used to describe and explain liquid-solid interface motion

during solidification. The next section concerns itself

with interface motion in pure materials during solidification and solid-solid transformations.

A couple of

theories of both types of transitions will be discussed.

Section

.5 will later extend these suppositions to

describe interface motion in binary systems. The key here

is to account for the additional variable of composition.

Sections

.3 and

.4 pertain to aspects of

interfaces which are vital prerequisites in understanding

boundary motion in binary alloys.

The last section gives

a perspective view of the remainder of the thesis.

2

1.2

Continuous Interface Motion in Pure Materials

Before attempting to understand binary interface

motion and the associated interface partitioning, a brief

treatise of interface migration in pure materials will be

given.

There are two general atomistic mechanisms of

crystal growth from the melt.

(a) The first is when the

interface advances normal to itself.

For this case the

nature of the interface is usually thought of as being

"rough" (1,2),or the driving force being sufficiently

large(3).

Wilson(4)

in 1899 was the first to propose a

kinetic theory to describe this type of freezing in pure

materials.

His prediction

V

=

is of the form

-MAG

(1.1)

where V is the growth rate, M is an interface mobility

which is dependent on temperature,

the molar free energy

driving free energy).

and AG is the change in

(equal but opposite in sign to the

This relationship

is still popular

today.

(b) The second mechanism

is when the interface

advances by lateral motion of steps or layers one or more

interatomic distances in height.

advance of the interface,

There is no normal

growth of an element of surface

advances only when a layer sweeps by.

A possible genera-

tion of such steps has been proposed by Frank(5) to occur

3

at screw dislocations.

It was later shown by Hillig and

Turnbull(6) that the growth rate by such a mechanism

V

(AG)

is

(1.2)

Interface motion by steps is believed to occur when the

liquid-solid interface is smooth(2), or when the driving

force is sufficiently small(3).

Regardless of the fact

many materials are believed to solidify by this mechanism,

the remainder of this thesis will be committed to a study

of normal interface advancement.

It will be called

"continuous interface motion."

The first theories of continuous interface motion in

solids were proposed by Turnbull(7)

and Mott(8) for

recrystallization. They derived rates of motion of highangle grain boundaries by the use of absolute reactionrate theory.

Turnbull bases his theory on the assumption

that the atoms traverse the interface individually.

final conclusion

V

=

-e

His

is

kT

AG

()exp

(-)

where e is the Naperian base,

a,

() aS

(-RT)

(1.3)

is the atomic jump

distance, h is Planck's constant, N is Avogadro's

AG is the molar free energy difference,

of activation, R is the universal

number,

AS a is the entropy

gas constant, Qa is the

activation energy and T is the absolute temperature in

Kelvin units.

4

If the structure of the interface is always assumed

not to change then equation

form of equation

(1.3) can be written in the

(1.1).

Mott's approach differs in that he assumes the

interface transport process is one where groups of atoms

of the parent grain melt and then solidify as a group onto

the daughter grain.

Mott's end result is of similar form

to that of Turnbull's

V

=

-e

(kT)

nAG

nLm

nLm

(h--)R-,exp(RT-)exp(-R-T-)

m

(1.4)

where n is the number of atoms in each group, Tm is the

melting temperature and Lm is the latent heat of fusion.

Experimental boundary migration rates by Aust and

Rutter(9), Rath and Hu(10), and Gordon and Vandermeer(ll)

show agreement with predictions of Turnbull's singleprocess theory, while Mott's group-process theory predicts

a velocity of several orders of magnitude higher.

A similar approach to Turnbull's has been proposed

specifically

for liquid to solid transformations

in pure

materials by Jackson and Chalmers(12). This analysis is

more detailed, though, because it considers geometric

factors and the probability

that an atom will be accommo-

dated by one of the phases at the interface.

The essential

feature of the Turnbull theory that interface motion is the

result of an individual atomic process is retained.

5

1.3

Equilibrium Segregation at Phase Boundaries

If theories similar to Turnbull's(7)

are tested for

materials without ultra-high purity large disagreements

between theory and experiment result. The pre-exponential

term is found to be much too small(ll).

Hence, impurities

or solute atoms influence interface motion significantly.

It is believed the solute retards the interface motion by

segregating to the interface.

For this reason it is of

interest to digress temporarily to allow one to comprehend

the interaction of a solute species with an interface.

Before the role of solute on moving boundaries

is

considered, an attempt will be made to convey that which

is known about segregation at stationary boundaries or

interfaces.

A means of characterizing equilibrium segregation at

boundaries will now be given.

If one assumes the struc-

ture of the interface is different than the bulk phase or

phases and hence the affinity for solute atoms is also

unequal, then it is plausible

to express the solute

chemical potential of the system in terms of a solute

interaction energy E(x) in dilute solution as

B

=

kTZnC(x) + E(x) + constant

The superscript B refers to the solute species.

(1.5)

The

distance x is in a direction normal to the interface.

equilibrium

( = constant),

At

C and E will be constant in

6

the bulk phase.

But if the boundary is considered

to have

a finite thickness, then C and E may vary with position in

the boundary to maintain

= constant.

In this thesis EB

will designate the value of E at the center of the

boundary.

An understanding

of the solute interaction energy E

may be conceived by the following discussion.

Consider

the addition of a solute species to a pure material while

keeping the addition small to minimize solute-solute

interactions.

If there is an attractive or repulsive

force on the solute atoms in the vicinity of a boundary

then this force can be perceived

as minus the gradient of

The solute interaction energy E is

a potential energy.

this potential energy.

One would expect a higher concen-

tration of solute where the interaction energy is lower.

In equation

(1.5) the first term may be thought of as the

entropy contribution

For a given

to

and E the enthalpy contribution.

, such as at equilibrium,

the smaller the

solute interaction energy E the larger the composition C

will be.

At equilibrium, if one sets the solute chemical

potentials of the bulk phase a and of the boundary equal,

then the ratio of solute compositions

CB(eq)

C

C

(eq)

E

=

exp(

is given by

B

)

(1kT6a)

7

The subscript B refers to the boundary.

equation, it follows that if E

>

From this

EB then CB(eq) > C (eq)

and the solute is surface active (adsorption of solute).

Conversely, if EB > E

then solute interface desorption

exists at equilibrium.

Several methods of calculating the solute

interaction energy EB for large-angle grain boundaries in

single-phase systems have been reported(13,14).

one assumes that the disordered

But if

structure of a random

high-angle boundary resembles that of the liquid(15), then

a natural extension is to set EB = EL and CB(eq) = CL(eq)

for a given temperature.

For this case, equation

(1.6a)

may be rewritten as

=

EB

B - ESS

kTZn

CS(eq)

[c(eq

L(eq)

=

(1.6b)

kTZn[K(eq)]

where K(eq) is the equilibrium distribution coefficient

(not to be confused with k which is Boltzmann's

K(eq) can be determined

constant).

from the equilibrium phase diagram.

Turning our attention now to liquid-solid interfaces,

a plausible

assumption for allowing one to estimate EB and

the corresponding boundary segregation might be to:

assume the liquid-solid boundary to be disordered

similar to the liquid phase.

C B (eq)

Then E B

and

EL and

CL (eq).

One possible means of experimentally determining EB,

at least semiquantitatively,

for liquid-solid interfaces,

8

is to utilize the famous Gibbs(16) adsorption isotherm

equation

B

_a

=

(1.7)

=B T,P

or for when the solute composition is small

-

rB

-

Da )

RT ( YnCTP

p(1.8)

is the number of solute atoms adsorbed per unit inter-

face area, a is the surface free energy per unit area, and

B

p

and C are the solute chemical potential and composition

present in the system that are being adsorbed.

From this

equation it is seen that if raising the solute composition

or chemical potential causes a reduction in the work a

required to form a unit area of the surface, then rB is

If

positive and solute is adsorbed by the interface.

addition of solute increases a then the solute species

will be rejected at the interface

a is experimentally

rB can be found.

(desorption).

Hence, if

measured as a function of (znC) then

But

rB

is the number of solute atoms

adsorbed per unit interface and not a composition at a

particular position in the interface. Nevertheless, from

FB the

nature of the segregation can be determined

and

also CB(eq) and EB (at the center plane of the interface)

can be estimated if one assumes a particular E = E(x) or

C B (eq) = C(x) for the boundary.

This method of characterizing solute equilibrium

segregation at interfaces by an interaction energy has

9

been used by Cahn(17) to develop a theory for boundary

motion during recrystallization (see Section

.5).

Cahn's approach will be extended in Chapter V to enable

the partitioning

at moving interfaces to be expressed as a

function of growth velocity for binary alloy

solidification.

1.4

Driving Force for Interface Motion in

Binary Alloys

Before discussing interface motion in binary alloys

it is worthwhile

to comprehend

the thermodynamic

funda-

mentals which allow such a process to take place.

At

constant pressure for binary alloys the composition

variable in addition to the temperature must be taken into

account if the thermodynamics

is to be understood.

One

can then predict when such a process is energetically

possible and determine

if it does occur.

the driving force for the reaction

These driving forces will be illustrated

graphically.

In binary phases the chemical potentials

(A

and

B)

of A and B are definedCl18

i

-

i

(~G/3n)

(1.9)

T,P,n

as the rate of change in the Gibbs free energy G when an

i-th component is added at constant temperature and

pressure.

The two chemical potentials

are related by the

10

Gibbs-Duhem

equation, which for constant T and P is

(1

C)diA + Cd1B

-

=

(1.10)

0

where C is the mole fraction of B.

This equation permits

calculation of the chemical potential of one component

from a knowledge

of the other.

The molar Gibbs free

energy, Gm = G/(NA + NB), is related to the chemical

potentials

by

Gm(C)

=

(1 - C) PA(C)

and by use of the Gibbs-Duhem

A

-

_

= Gm

(C)

(1.11)

equation

C( m

C

(1.12)

B_

B

Equation

+ C

Gm +

(1.9) expresses

chemical potential.

(1 - C)(--)

the important property of the

It is the increase in free energy of

the entire system when an infinitesimal amount of one

component is added reversibly (per mole added). From this

property we have the important condition that for equilibrium the chemical potential must everywhere have the same

value.

Equations

(1.12) form the basis of the popular

graphical methods of tangents(19). They express the fact

that a tangent drawn to the molar free energy curve in

Figure 1.1 at the composition of interest intercepts the

C = 0 and C = 1 vertical axis at a value of Gm equal to

11

the chemical potential of the component. Hence a common

tangent among two or more phases implies equality of

chemical potentials and equilibrium (see Figure 1.2).

A

tangent to a Gm versus C curve also has an important meaning for reactions of a phase with composition change.

equation of a line tangent to Gm at C = C

Gm(C,C

)

=

(1 - C)A

If an infinitesimal

(C ) + C

is

(Ca)

(1.13)

amount of material of composition

C were to be added reversibly to

of composition C , then

Gm (C,C ) would be the change in free energy of

of material

The

added as in Figure 1.3.

composition of material added.

per mole

Here C is the

It may be quite different

from C , the composition of a, which is the value of C

where the line is tangent to the

free energy curve.

The

free energy change AG per mole reacted for diffusionless

reactions of composition C

from

to

is obtained

graphically in Figure 1.4 by reading the vertical distance

between tangents at C

(incidently the distance between

tangents for the case coincides with the distance between

curve to curve at C0).

Analytically

the free energy

changes per mole of B is

AG,, =

(l-CH

O)

0a

-

AC + C (B a

~0jB

The free energy change AG per mole

B

a

(1.14)

formed in a closed

system that transfer small amounts of components from a at

12

composition C

to

at a different

composition of C

is

attained graphically in a similar way as before by reading

the vertical distance between tangents at C

1.5).

This free energy change per mole

expressed if C

AG

=

is changed to C

(1 - C) (

-

formed can be

in equation

) + C

&

(see Figure

(1.14)

- hB

(1.15)

This substitution is necessary because the free energy

change desired is per mole

formed and 1 is no longer of

composition C.

To inquire if a solid can form from a single-phase

liquid of composition C

one draws a tangent to GL at C0

and sees if the free energy curve of any solid phase lies

below the tangent

(see Figure 1.6).

The composition range over which G

lies below the

tangent gives the range of composition of solid that can

form.

At temperatures

above the liquidus no solid can

form.

At the liquidus one solid just touches the tangent.

It is the only solid that can form and it must form with

the equilibrium composition. At lower temperatures an

increasing range of solid compositions can form.

To take advantage of the isothermal aspects of the

graphical methods this same range of solid compositions

can be presented

isothermally

by varying the liquid

composition CL.

At a given temperature the range of

thermodynamically possible solid compositions C

that can

13

form from a liquid of varying

compositions CL, is shown

in Figure 1.7 as an area enclosed by the curve where

AG = 0 (OABEP).

The right-hand most point on the curve E

depicts the equilibrium compositions. The tangent to the

liquid touches the solid only at one point

in Figure 1.8).

(see tangent 1

As the liquid composition moves to the

left (tangent 2) the range of possible solid compositions

at first increases and then decreases

again.

The maximum solid composition(C(T o ) in Figure 1.7,

tangent 3 in Figure 1.8) is the composition where the two

free-energy curves cross.

Only one liquid composition,

C(To), can give this solid.

If the liauid is either more

or less supersaturated this maximum solid composition

ceases to be possible.

Diffusionless

transformations,

shown as a line OB of slope 1 in Figure 1.7, can only

occur if the liquid composition

is below this crossover

composition(20). Following the useage in other transformations(21,22),

we shall call the condition of equal free

energies the T

condition and the composition C(To).

phase diagram T

solidus lines.

On a

forms a line between the liquidus and

The line marks the upper limit to the

liquid compositions and temperatures for diffusionless

transformations.

compositions

It also marks the upper limit to the

and temperatures

of solid that can form

isothermally from liquid of any composition.

14

interest are shown

Two other curves of thermodynamic

in Figure 1.7.

These are the lines where chemical poten-

tials of a component are equal in liquid and solid.

line

E, APB = 0; for line PE, AA

lines cross we have equilibrium.

For

Where the two

= 0.

These lines bound the

regions of the figure where a particular

component

solidifies with a decrease in chemical potential.

In the

triangular region OEP both components would experience a

decrease in chemical potential upon solidification. In

this joint composition range the line tangent to the solid

free energy versus composition curve lies everywhere below

the line tangent to the liquid.

Both components

independently experience a decrease in free energy upon

solidification. Outside the triangular region but within

the AG = 0 curve the tangent lines cross and although the

overall free energy decreases upon solidification, one of

the components experiences an increase in chemical potential.

Solidification

in this domain can only occur if the

two species do not solidify completely

one another.

independently

of

One species enters the solid with an increase

in its chemical potential because it is either passively

trapped by the advancing solidification front or because

it is a required participant

in an independent

solidifica-

tion reaction mechanism involving several species which

leads to an overall free energy decrease.

In either case we

will define "trapping" of a component to occur at an

15

interface when that species experiences an increase in

chemical potential there.

It is worthwhile

to describe the above conditions

quantitatively for one simple case, that of dilute solution

for both liquid and solid.

Then the chemical potentials

are given by Henry's Law for the minor component

B

=s B

B

L =BL

+ RT

n ys C

(1.16)

+

n yL CL

(1.17)

RT

where the B's and y's are related constants that depend on

temperatures and reference states. We may eliminate the

constants by noting that the chemical potentials are equal

at equilibrium when C s = C s (eq) and CL = C L (eq), then the

change in chemical potential across the solidification

front is

B

AP

B

PUs -

B

L

=

RT

n

C s C L (eq)

Cs (eq)

s

In terms of the distribution

(1.18)

~L

coefficient K at the inter-

face, defined as Cs/CL, and its

equilibrium value,

K(eq) = C s (eq)/CL (eq), this becomes

AP

B

=

RT

n

K/K(eq)]

(1.19)

The minor component experiences no change in chemical

potential when

Cs

=

K(eq) CL

(1.20)

16

This is a straight line OE with slope K(eq) through the

When K < K(eq), A B < 0.

origin in Figure 1.7.

This is

The area above line OE

the region below the line OE.

For the major component

corresponds to "solute trapping".

Raoult's Law hold and

CL (eq))

- C(1 - C

RT Zn (1 - C(eq)) (1 - C

5

L

A

A

=

(1.21)

The major component experiences no change in chemical

potential when

[Cs (eq) - Cs]

=

- C(eq)][CL(eq) - CL]

[1 - C(eq)/

........

.(1.22)

This is a straight line PE of slope [1 - C(eq)]/[l

- CL(e q ) ]

[Cs(eq), CL (eq)] in

= 1 through the equilibrium point

Figure 1.7.

The regions above and below the PE corresponds

respectively

to AiA

less than or greater than zero.

Solvent

trapping would occur below PE.

The AG = 0 curve is given by

(1 - C)

s

A

+ C

s

ASB

=

0

(1.23)

This curve must pass through the points 0, B, E, and P.

1.5

Continuous Interface Motion in Binary Alloys

In Section 1.2 it was shown by Equation

the response of an interface in pure materials

(1.1) that

(one

component systems) to the conditions at the interface can

17

be expressed by

V

=

-MAG

(1.1)

or in general, in terms of the variables V and T

f(V,T)

=

0

(1.24)

For binary systems the additional variable of

composition must be taken into account and two interface

response functions are needed to describe the interface

motion.

For an a+- transformation

fl (Ca ,CV,T)

=

0

f 2 (Ca ,CV,T)

=

0

where C a and C

the

and

these functions are

(1.25)

are the solute interface compositions of

phases.

Such response functions could equally

well be solved for the response, V and Ca, in terms of the

temperature T and

interface composition C.

V

=

gl(T,C)

Ca

=

g2 (T,C)

(1.26)

Such a form of the response functions are especially

valuable when considering a solid state transformation

under steady state conditions.

For this case C

equal to the overall solute composition C

is

of the system

and the temperature T is the imposed variable.

18

For steady state solidification te

desired response

functions are

since C

= C

T

=

hl(V,C

CL

=

h 2 (V,C s )

s

)

(1.27)

and the growth velocity V is now a

conveniently controllable parameter.

It should be noted

no matter which form of the response functions are chosen

they describe the same relationship

and are equivalent.

From this view point it is readily evident that the

principles

of solidification

are equivalent

to those of

interface motion during solid state transitions, and basic

approaches

applicable to one should be satisfactory

for

the other.

For solidification,

due to the high diffusivities

the liquid and the usual comparatively

velocities,

in

small growth

it is customary to assume the liquid and solid

interface compositions are not substantially different

from equilibrium compositions. Such a condition is called

"local equilibrium"

this assumption

at the interface.

The significance of

is that the interface compositions

independent of growth velocity V and dependent oly

interface temperature T.

and solid compositions

are now

on

For any temperature the liquid

can be read from the liquidus and

solidus lines on the equilibrium

response functions are known.

phase diagram; hence the

19

If the above assumption

is not made two common

approaches have been used to determine the response

functions for the solidification process: Absolute

reaction rate theory and irreversible thermodynamics.

A theory for determining the response functions for

binary solidification using the absolute reaction rate

approach has been developed by Jackson(23).

It is an

extension of the work by Jackson and Chalmers(12)

component systems.

to two

Such an extension can easily be made

since an inherent assumption

of the previous work is that

the atoms traverse the phase boundary individually. Hence

the following convenient assumption of the Jackson theory

was a natural one:

the rate at which j atoms of each

species leave a phase and traverse the interface is proportional to the mole fraction of the species in that phase.

This assumption allows Jackson to develop an analysis which

lends itself

readily to physical interpretation. Details

of this theory will be given in the next chapter.

The more popular approach to the problem for binary

solidification

has been through the use of irreversible

thermodynamics. The starting point for these theories is

by assuming a relationship

similar to equation

(1.1) for

each atomic species, that is the flux of each species

across the phase boundary is linearly proportional

to the

gradient of its chemical potential. A thorough analysis of

these theories will be given in Chapter IV.

20

Since it is well known even traces of a second atomic

species retards interface motion during recrystallization,

Cahn(17) has formulated a theory to account for the interface drag of a second species on interface motion.

It is

assumed when the material is pure equation (1.1) is valid.

When a solute species is present its drag on the interface

is determined and in turn the resulting response functions

can be found.

The nature of the above solute effect

depends on the magnitude

of the solute interaction energy

EB relative to the interaction energy in the bulk phase.

These are the same equilibrium solute interaction energies

as found in equations

(1.5) and (1.6a).

An extension of

this Solute Drag Theory to binary solidification is given

in Chapter V.

The necessity of this alternate approach to

determine the interface partitioning during binary solidification was found to be needed since there are defects in

the previous two methods.

These deficiencies will be

covered in Chapter IV.

1.6

Scope and Objective

of Thesis

The purpose of this investigation

detailed examination

is to make a

of the response of a solid-liquid

interface to various conditions at the interface.

Specifically, this study has been made to gain insight

into the relationships between solute partitioning (solid

and liquid interface compositions), the interface

21

temperature, and the growth rate during binary alloy

solidification. Such relationships are called "response

functions."

A knowledge of the response functions is of utmost

importance in the field of solidification

since they are

needed boundary conditions to differential equations which

are capable of describing

Such a mathematical

the kinetics of solidification.

analysis in turn can help in

predicting and controlling cast alloy properties.

If it is assumed that the interface is highly mobile,

then even for small deviations from equilibrium the interface velocity is expected to be large.

For this case it

is expected that the solute partitioning

should be a

function of only the interface temperature and not

dependent on the growth rate.

interface compositions

Such a condition where the

are close to the equilibrium

compositions is called "local equilibrium." Since most

solidification

studies are carried out at low velocities

the condition of local equilibrium

has gained wide

acceptance as a valid form for the response functions.

first objective of this investigation

The

is to test the valid-

ity of local equilibrium under extreme solidification conditions.

In Chapter II it will be shown that compositions of a

resulting solid after freezing were found to be larger than

the stable or metastable

solidus composition at any tempera-

ture and therefore a departure

from local equilibrium

at the

22

liquid-solid interface occurred. This investigation was

performed by studying the zinc-rich solid phase in zinccadmium alloys after splat cooling.

Chapter III will then

concern itself with thermodynamics aspects of solidification when the solid composition lies in various regions of

the equilibrium phase diagram.

With the above experiments in mind, previous theories

on non-equilibrium

partitioning

With the aid of the experimental

are examined in Chapter IV.

results in the zinc-

cadmium work, serious deficiences have been found in each

of these theories.

Since most of these theories are

irreversible thermodynamic

in nature, special attention

is

given to this type of method and surprising conclusions are

drawn.

Chapter V will be concerned with attempting to

overcome the above shortcomings by using the solute drag

approach.

Before proceeding

to the next chapter it should be

noted that the major portion of Chapters II*, III**, and

IV** have been published.

J. C. Baker and J. W. Cahn, Acta. Met., 17, 575,

(1969) .

** J. C. Baker and J. W. Cahn, "Solidification,"

Soc. for Metals

(1970) .

Amer.

23

Cn

-4

4-i

-4c-J

G)J

Z

w9 '3N3

338

0 -1tV1

24

IIQZ

::L

I!

Zi

0n3

LI)

'I

4-J

(~~~)

C~~(

C

Cr ~

-

-

t

biJj-

W 9E' Agd3N3

33.

V1OA

,1

:tt

25

vL

,E

,2L

.-

Z

X

°

1o~~

C

o

.H

.

Gc *C

Z

Ik!3N3

333 A

N OVW

<

C

C-o

'

26

mr cQ

0

04.

0

0

-

o

o.~

0

E

0]0

0J4H

o

C-)

0

LiJ

II

C.-

.

0

1)

C

o-C

*'-1=

cn

,00

W

w9 ' AE)93N3 3-3DJ

:

27

cn~

M t

Cd

Cd

4JO

Cd

Cd-

Cd

Cd

Cd

Ci

2;

I

O4J

Q

Cd

Cd

Cd

o

c

c)

Cd

oi-

'I

0

Cd

0

Cd

Cd

0

Cd

Cd

Cd

CC

9d: N] 33

A D 8]3N]3

3J

V0<

a

HV-10

Cd

Cd

Cd

28

u0

I

i

v:

0

0

'0

E

©

0

ZJ

0 C

z Js

'~4 -

cn~~0

0 -

-

0<<CDL

)

~.

S4-

C

0~~~~Jr

-

'

~~~~~

-4

U>

00_

l

i)

0

Ad3N3 33WJJ VtO0J

,°

<

I

'-4E

29

iE

I

-

,

o

4-~ .;4

-

4-4

C

C~0(D-4-,

CUOC.

-~ CC

4_

r-:

tCH

-

aC

r

O

C.n

C.CCJ

~ Zn

C. -400

-

O0

0

- .

-

0;

2 ,.)~- 0

all0

5

~

W

0004-

02

C)

1-4

SO '30V8J31NI 1V NOIISOdVJOD clOS

~-'

0

4

Zn

X

02

*~

Z

)

0

C4-4

.0 C

-1) 0-- r0

o o~--a

C)

0

C C.) Zn

C)

C.iCr) Zn

Zn '4-r

0 H;

0> >Hr'

rLxU

0

j-~2

~$_,'4-j

: -oo rO

0

J-

"

4J

V

CC1-4 z 0 0 --~

0

CY

0

'. 4Jz0s

C.

U C

-z

I-

0

Z~T,~.-Q

C.

Zn-i

OC1);.)

o

. ,_~h

r1

c*1

-;C)0

m~~~1-

C) 4-1 Zn ,r

0A

C.)

Z

C.

4Zn

- -

30

-J

C0

0%>

C

cr

0

-4

4t

_

Li

CJ

v,

X_

oW

O<

-

U-

O

11

U)I

7a)

co

0

h a

4-4

1

!Dd3N3 338

dWV1OIN

31

Chapter II

SOLUTE TRAPPING BY RAPID SOLIDIFICATION

II.1

Introduction

Equilibrium between solid and liquid phases of metal

alloys implies that the position of the phase boundary is

fixed, i.e. the net rate of growth, V, is zero and that

both phases are of uniform composition, but the compositions

of the solid and melt are usually different.

brium compositions

These equili-

are dependent on temperature; the

possible compositions of solid and liquid correspond to two

lines on the phase diagram, the solidus, below which in

Figure 2.1 the solid is stable and the liquidus, above which

the liquid is stable.

If the liquid-solid

small rate

interface is allowed to move at a

(Vsmall), the solid and liquid phases need not be

of uniform composition.

But for all practical purposes, the

solid phase at the interface

can be assumed to be in equili-

brium with the liquid at the interface

CL(i) = CL(eq)).

(Cs(i) = C(eq)

and

In this thesis the above condition at the

liquid-solid interface will be referred to as "local

equilibrium."

For large growth rates it is questionable

condition of local equilibrium

if the

at the interface holds.

Consequently,

the objectives

chapter are:

Cl) to obtain high growth rates by the method

of the investigation of this

32

of splat quenching

and (2) to ascertain if there is a

detectable departure from local equilibrium at the interface for the case of large growth rates.

If we measured the temperature at the liquid-solid

interface during rapid solidification we would know the

equilibrium composition of solid from the phase diagram for

that temperature.

Then we could check the validity of local

equilibrium at the interface by comparing this equilibrium

composition with the actual composition of the resulting

solid.

But it is a major experimental

the temperature at the crystallization

problem to determine

front.

If this

temperature is unknown during the solidification, then for

most alloy systems any observed solute redistribution

be rationalized

can

from the assumption of local equilibrium at

the interface, since the composition of the solid can be

made to match a stable or metastable equilibrium solid

composition by choosing the appropriate solidification

temperature

above or below the eutectic as indicated in

Figure 2.2.

It is possible to avoid this problem of temperature

determination by selecting an alloy system with a retrograde

solidus (see Figure 2.3).

since a retrograde

The reasoning is as follows:

system has a maximum in the solidus

[Cs(eq max) > C(eq)],

if a composition of the actual solid

can be measured which is greater than the retrograde maximum

in the equilibrium

solid composition

Cs(i) > C(eq

max)], a

33

positive departure from local equilibrium at the interface

must have occurred

Hence, for this case

Cs(i) > Cs(eq)].

we can measure a departure from local equilibrium without

the temperature being known.

II.2

Experimental

The zinc-cadmium

investigation

system was chosen for this

(see Figure 2.3).

The solidus of the zinc-

rich end of this alloy phase diagram was reported to be

retrograde by Owen and Davies(24).

The retrograde

solidus

was confirmed by the present author using X-ray lattice

parameters to measure solid compositions at various temperatures.

High-purity

zinc (99.99%) and high-purity

(99.99%) were sealed in an argon atmosphere

melted together, and quenched

in water.

in

cadmium

vpyrextubing,

Portions of these

master alloys were then remelted and splat cooled to -1960 C.

The shock-tube method of splat quenching

al(25) was utilized.

of Duwez et

This technique employs a shock wave to

eject liquid metal through a small hole in a crucible,

atomizing the liquid in process.

The liquid globules

are

rapidly spread on a copper substrate.

0 C and

The resulting metal foils were kept at -196°

analyzed on an X-ray diffractometer.

Unit cell volumes

(0.866 a2c) of the zinc--rich phase were calculated

and

plotted versus weight per cent cadmium of the initial liquid

from zero to 5% (see Figure 2.4).

34

II.3

Discussion

The unit cell volume of the zinc-rich phase in Figure

2.4 can be considered

as a measure of the concentration

cadmium in solid solution.

of

Since we find that the unit

cell volume is linear with respect to the composition of

the initial liquid, we conclude that solid of compositions

up to 5 wt. % cadmium have formed.

The maximum composition

of equilibrium solid in accordance with the retrograde

phase diagram is 2.6 wt. % cadmium.

Consequently,

the solid

solubility has been increased beyond the maximum solidus

composition and a positive departure from local equilibrium

at the liquid-solid interface has occurred in the solid

composition, i.e. C(i)

> C(eq).

We are now in a position to compare the result of

increasing the actual solid composition beyond the

equilibrium composition of the solid with present theories.

There are two basic types of theories that are shown invalid

by this experiment; one by Jackson(23)

is based on reaction

rate theory, the second by Borisov(26)

is a thermodynamic

approach.

Let us first consider Jackson's kinetic description

of alloy solidification.

two assumptions:

It is developed on the basis of

(1) reaction rate theory can be applied

independently to each species, and (2) the rate at which j

atoms of each species leave a phase and traverse the

35

interface is proportional

in that phase.

to the mole fraction of the species

From these two assumptions Jackson attains

the equations for each atomic species

Vj

m

=

KJ C(i)

VD

F

=

K3

FLCD(i)

m

S

(2.1)

where Vm is the rate at which atoms of the j species cross

the interface to join the liquid, V

is the rate at which j

atoms cross the interface to join the solid, and

K j = AGjvNJV

j

exp(-QJ/RT)

(in the notation of the cited

paper) is a function of temperature but not of composition.

The net rate of growth of each species is equal to the

difference between V

Vj

=

From equations

and Vm and is given by the equation

VF -F V m

(2.1) and

(2.2)

(2.2) it can be shown Jackson's

analysis predicts a negative deviation in local equilibrium

for the solid at the interface, C(i)

< C(eq),

contrary to the results of this investigation.

as follows.

For species B at equilibrium V=

which is

The proof is

0 and equation

(2.2) becomes

VB

F

=

=

VVB

m

(2.3)

36

Combining equations

(2.3) and

Km C S (eq)

=

m

(2.1)

B

KF

F CL (err)

VB is positive for solidification

equation

(2.4)

and is given by

(2.2)

= VB

VvB =V

Combining equations

K

C

L

F

and substituting for K

(2.5)

(i)

(2.5) gives

-

K

B

m C S (i)

from equation

m

VB

VBm

(2.1) and

BB

V

-

B CL(i)

=C(eq)K

L

F

[

()

(2.6)

(2.4)

CS (i)

CS(eq)

(2.7)

For solidification we must have a decrease in free

energy, hence it can be easily shown any deviation

local equilibrium in the liquid composition

from

is such that

the liquid composition at the interface is less than the

liquidus composition

CL(i)

Equations

<

CL (eq)

(2.8)

(2.7) and (2.8) yield

C S (i)

<

C s (eq)

(2.9)

Hence, Jackson's theory predicts the wrong direction for the

deviation from local equilibrium

and the theory is invalid.

37

We now turn to Borisov's theory, which makes the

thermodynamic assumption for a binary system that the

chemical potentials of both species must decrease during

solidification,

i.e. the values of the chemical potentials

at the interface must satisfy the following condition:

A (

0

<

i)

USL

(2.10)

PB(i)

Equations

-

<

BL(i)

0

(2.10) will now be shown to be inconsistent

with the experimental results, C(i)

> C(eq),

hence making

Borisov's theory also incorrect.

At equilibrium for species B

B

1L(eq)

=

ps(eq)

(211

(2.11)

Except at critical unmixing points and spinodals we have

the following condition for each species in any stable or

metastable phase

, (i)/C (i)

>

0

(2.12)

For solidification with a decrease in free energy equation

(2.8) holds true and when combined with equation

L(eq)

>

vL(i)

From our experimental result, C(i) > Cs(eq), and

equation

(2.12)

(2.12) gives

(2.13)

38

US(i)

Combining equations

vS (eq)

(2.14)

(2.11), (2.13), and (2.14)

_

-B(i)

S

Therefore,

>

L

the assumption

0

>

p(i)

of equations

(2.15)

(2.10) and Borisov's

theory are invalid.

It should be pointed out that equations

(2.10) are

not necessary thermodynamic conditions for solidification.

The thermodynamic

transition.

requirement is AG < 0 for the overall

This permits A

>

0 for one of the species.

It is now of interest to see why theories like

Jackson's and Borisov's fail to agree with our experimental

result.

Both types of theories make the inherent assumption

that some spontaneous activity is required of each species

during solidification.

the solid are inactive.

The atoms that do not traverse to

Thus each species must lower its

free energy on solidification. Experimentally we find that

the cadmium atoms experience

potential.

an increase in chemical

This means that if the cadmium atoms could act

independently

they would attempt to avoid the solid.

the time the cadmium's potential

passive.

During

is being raised it must be

The cadmium is trapped in the solid by the

solidification

front and if it could have been active

would have remained in the liquid.

it

39

There is one atomistic theory which has in it the

basic passivity of the solute and which therefore predicts

the correct deviation in solid composition from local

equilibrium.

This is Chernov's

of surface active solute atoms.

theory(27)

These solute atoms seek

the interface and are subsequently

of the crystal grows.

for the trapping

buried as the next layer

It is during the burying that they

are passive and their chemical potential

is raised.

If

they can diffuse they attempt to remain in the surface.

The author believes Chernov predicts the correct

departure because it is inherent in his beginning assumptions and not a product of the solution to his diffusion

equation. The disputed assumption is:

the initial composi-

tion of the new solid layer is identical to the interface

layer from which it formed.

Any later change in composition

of this solid is then due to diffusion

in the solid.

Hence,

for a surface active solute species this total initial

capture of solute atoms is independent of the layer's

lateral growth and neglects

solute escape by interface

diffusion ahead of the moving layer

(the author feels this

may be an important effect especially at small layer growths).

An analysis believed to be more realistic than the one

above is given in Chapter V.

It also predicts a positive

deviation in solid composition from local equilibrium when

the solute atoms are surface active.

40

II.4

Appendix

A.

Verification

of the Retrograde

Solidus in

Zinc-Cadmium

The validity of the conclusion of this experiment

requires that the solidus including its metastable extension

below the eutectic never exceeds the composition value at

the retrograde maximum.

But theoretical and experimental

tests were performed to check that the solidus indeed has a

maximum, and the metastable extension was shown theoretically to continue to decrease monotonically.

The various equilibrium solidus compositions were

calculated by utilizing available thermodynamic data from

the literature(28)

and the following expression derived by

Thurmond and Struthers(29).

kn

(A +

LB)--Bs

+HL)

C (eq)

(AHf

]

C

(e q )

CL

L (eq)

=

T

RT

AB

AfA2B

-

-RT

(2.16)

Both the liquid and solid solutions are assumed to be

regular solutions.

AHf and ASf are the heat of fusion and

entropy of fusion at the melting point of solute B, AH- and

-B

AHL

s

are the differential

heat of solutions of the solute in

the solid and liquid phases.

For regular solutions the

B

above three AH's and ASf are constant.

side in the Zn-Cd system they are(28):

For the zinc-rich

41

AHcd

Afif~

153

~cal.-C

f

= 201530

cal.

=

~~

~~~~~~L

Cd

ASf = 2.58 cal/°.

TCs

=

6904 cal.

Using CL(eq) values from the phase diagram, Cs(eq)

values have been calculated

at the temperature where the

experimentally determined phase diagram predicts a

maximum

(600°K) and at the eutectic temperature

The two calculated

solidus compositions

600°K) and 1.23 at/o (at 539°K).

0 K).

(539°

are 1.30 at/o

(at

Hence, these two

composition values predict a retrograde

solidus, and are

in close agreement with the equilibrium hase diagram

values(24) of 1.39 at/o and 1.20 at/o.

Let us now study equation

(2.16) in detail for the

Whenever

Zn-Cd system.

-B

AHs

the right-hand

B

-B

(2.17)

>> (AHf + AH)

side of equation

(2.16) is always negative

and increases in absolute magnitude as the temperature T

decreases.

The above implies

n[Cs(ea)/CL(eq)] + -A and

Cs(eq)

0 as the temperature T tends toward zero degrees

Kelvin.

For the zinc-cadmium

system expression

(2.17) is

obeyed strongly. So strongly that heat capacity differences

cannot produce appreciable

changes in it.

Hence, below the

eutectic temperature the metastable equilibrium solidus

compositions will continue to decrease with decreasing

temperature.

42

For a maximum to occur in the stable portion of

AHs and ETmA - T (eutectic)

a solidus, it is desired that -B

be large.

For systems where AHS < (AHf + AHL) the

solidus cannot have a retrograde maximum at any temperature.

The maximum in the solidus was checked experimentally

by X-ray lattice parameter measurements.

First, alloys of

3.5 w/o Cd were heated into the two phase liquid-solid

phase diagram region and were allowed to equilibrate at

the supposed temperature where C 5 (eq) is a maximum and at

a lower temperature.

Both specimens were quenched in

water and examined by X-ray lattice parameter measurements

at -196°C.

It was found that the specimen with the

higher equilibration

temperature had a larger unit cell

volume at -196°C and hence was of higher composition.

This

in turn supports the retrograde nature of the solidus.

B.

Verification

Solid Phase

of Presence of Only a Single

The second precaution

was to examine the various

splat cooled alloys by transmission electron microscopy.

The test was to determine

if only the zinc-rich

phase in

Figure II.3 was present as indicated by X-ray analysis,

or if the cadmium-rich

amounts.

phase was also present in small

If the s-phase is the only phase

alloy compositions

resent when

greater than C (eq) maximum are splat

s

cooled, then all the cadmium is in solution in the ~ phase

and C s > C (eq).

s '

This is what was found by the

43

transmission electron microscopy (see Figure II.5).

Only

one phase appears to be present and the grain boundaries

are clean.

If a phase particles

invalidate the experimental

But the actual finding of no

had been found, it does not

conclusion

that C s > Cs(eq).

phase present does support

the conclusion that the composition of cadmium in solution

is greater than the equilibrium composition.

One would expect if the cooling rate was decreased

sufficiently, the system would tend toward equilibrium

during the freezing process and form both

and a phases.

The necessary segregation needed for the formation of

these two phases most likely would occur by dendritic

solidification.

Figure II.6 is a micrograph of a

replica of the surface of a Zn-3.5 w/o Cd alloy cooled

by the piston and anvil technique(30).

appears to consist of

particles.

The specimen

dendrites and a interdendritic

The rate of cooling in the piston and anvil

technique(30)

is believed to be 105(°C/sec), where as

the splat cooling methods

leads to a cooling rate of

approximately 107(°C/sec).

44

e

._

©

0

.-4

F -CT

.

o

E

©n

r~

0

0

0Hu

--

-4

r

3 n 1v

3d

3i

45

cJ

(J

o

-j

o~~ ©

0~~~~~

u ,

C'4

0~~~

I-~~~~~~~~~~

3 n

v d3d vq31

0

a _

46

0

0

C~~~~~~C.1

(~~~~~~)

~

0~~~

z~~~~

s

2~~~~

a~~~~~a

C

Q

lpIC

_I

C

0',I

t~

D

U~~~~~l

_

CC~~~~~~~~~l

;~~~~~~~~~~~~~

,0

cO

E

B3

W LJVW13 dV3-L

N

47

30.40

0

o

C0(0

I

<r

30.30 D

-_

0

-J

-J

0w-

2.00

1.00

WEIGHT

Figure II-4.

3.00

4.00

% CADMIUM OF INITIAL

5.00

LIQUID

Plot of unit cell volume of zinc-rich solid at

-196°C against weight per cent cadmium of

initial liquid.

48

Figure II-5.

Electron micrograph of Zn -3.5w/o Cd which was splat

quenched to -196°C.

130,000X@

-

49

rC'

.

-.4e

L..

'

r

S

l ~ br

c

t

,

Y

a

V

f

_

t.

v~-

8i,-O X

.t

'- ,,'f

9~ ~ ~C ,r ~i ~ (~~Y

-

Figure II-6.

t

Electron micrograph of replica of Zn -3.5w/o Cd which

was cooled by the piston

and anvil

technique.

8 ,0OOX.

50

Chapter III

THERMODYNAMIC ASPECTS OF SOLIDIFICATION PROBLEMS

III.1

Introduction

The mathematical

analysis of an N-component

solidification problem with one solid phase consists of

setting up 2N differential

(2N-2) for interdiffusion

equations;

2 for heat flow and

in the two phases.

In addition

the initial conditions and the boundary conditions must

be given.

Of these, (2N+2) boundary conditions pertain

The reason this number of

to the liquid-solid

interface.

boundary conditions

are needed is that the interface

not at a fixed position and additional

is

conditions are

needed to specify the interface velocity. The interface

boundary conditions are:

(1) Continuity

of temperature.

It is believed

that the heat transfer across the interface is sufficiently

rapid that even in the most extreme heat fluxes temperature remains continuous across the interface.

(2) Conservation

of heat.

This condition includes

a term for the latent heat of fusion L

and thus involves

the velocity V

Ks(VT.n)sm - KL (VT .n)L

=

L V

(3.1)

51

(3) N conservation of mass equations; one for each

component

Ds (VC.n)s - DL(VC.n)L

=

(Cs - CL )V

(3.2)

These also contain the velocity.

(4) N "response" functions which describe the

response of the interface to the conditions at the

interface. These would give N quantities, e.g. the

velocity of the interface and the composition of the solid,

in terms of the instantaneous

temperature,

conditions; the interface

the composition of the liquid, and the orienta-

tion and defect structure of the interface. This section

will consider the thermodynamic aspects of these response

functions.

For a single component system if we ignore the last

three factors, such a response function would be

f(V,

AT)

=

0

(3.3)

or equivalently when solved for either V or AT

V

=

g(AT)

(3.4)

AT

=

h(V)

All three equations express the same relationship

should be fully equivalent.

and

If we impose a velocity

note the interface temperature and then in another

and

52

experiment apply this AT we should observe that the system

responds with the same V.

For a binary system the two response functions

would be

Cs, V, T)

=

0

f 2 (CL, Cs, V, T)

=

0

fl(CL

(3.5)

which might be solved for the response, V and C,

in terms

of the interface temperature T and CL

V

=

gl(T, CL)

(3.6)

CS

=

g 2 (T, CL)

Such a response function could equally well be expressed in

terms of the compositions that would be found for a given T

and V.

CS

=

m 1 (T, V)

CL

=

m 2 (T, V)

(3.7)

As we shall see this form is convenient

from a thermodynamic

point of view. Another way of expressing the respone

functions would be to express the temperature T and CL in

terms of a given V and C

53

T

=

h1 (V, C)

CL

=

h 2 (V, Cs)

(3.8)

This is a valuable

form for steady state solidification.

These four ways of expressing the response function are

fully equivalent

to each other and an experimental determina-

tion of one form should be adequate for reexpression

the other forms.

in all

Because they are boundary conditions to

differential equations one form or another may be convenient

for a particular

experimental

geometry but for a particular

system the relations should be universal.

Thermodynamics places only general restriction on the

response functions.

It does not specify them.

For the

single component it specifies that the sign of V be related

to the sign of AT.

For the binary system it specifies only

that for a given T, solidification

(V > 0) requires that C

5

and CL lie inside or on the boundary of the curve OABEP of

Figure 1.7. For purposes of mathematical analysis such a

general restriction is insufficiently precise. We have to

know more about the response functions.

Because these response functions are boundary

conditions to a solidification

problem it is difficult to

perform experiments that isolate them sufficiently clearly.

Ideally interface compositions, temperature, and velocity

should be measured directly.

Even in the single component

54

system the interface temperature is often inferred from

bath temperatures with or without a heat flow correction.

In multicomponent

systems as we shall discuss, equilibrium

at the interface is usually assumed(31) without even an

attempt at experimental verification.

III.2

The Assumption of Local Equilibrium

If we assume that the boundary is so mobile that V

is large for any deviation

from equilibrium,

functions become the conditions

the response

for local equilibrium,

of which there also are N in number.

Hence, for one

component

AT

=

0

for all V

and for two components

(3.9)

the compositions at the interface

are

Cs

=

C s (eq)

=

m 1 (T, 0)

(3.10)

CL

=

C L (eq)

=

m 2 (T, 0)

for all V.

The assumption is valid whenever the deviation from

equilibrium,

expressed as AT, C s - C s (eq), or CL - CL(eq)

is small compared to the total temperature and composition

ranges in the problem.

Although

appears in these conditions,

vation conditions

can proceed.

the velocity V no longer

it still appears in the conser-

(2) and (3), and the mathematical

analysis

55

The popularity

of local equilibrium

as an

assumption rests on its expected widespread validity for

most solidification problems which involve rather low

interface velocities,

and the fact that it gives a form

to the response function that permits one to begin calculation of solidification

of the assumption

problems.

The test of the validity

could come from two kinds of experiments:

the simultaneous measurement

or checking the applicability

of all the interface variables

of predictions of calculations

made using the assumptions. The former test has never been

made and the latter test is most usually made qualitatively.

Qualitative predictions from the assumption can only

show consistency or inconsistency.

For instance we can, by

using the assumption of local equilibrium, predict an

enhancement of solid solubility in a eutectic beyond the

maximum phase diagram value simply by invoking the assumption that the eutectic has been suppressed and solidifica-

tion proceeds on metastable liquidus and solidus extensions

below the eutectic.

(Figure 3.1)

However unless we

simultaneously measure the interface temperature, we will

not know whether we produced a deviation from local

equilibrium or actually suppressed the eutectic reaction.

Thus even the enhanced solubility produced by rapid

solidification is by itself inadequate to prove that a

significant deviation from local equilibrium was produced

because the metastable solidus usually continues to

56

increase in composition.

In the Zn-Cd system which has a

retrograde solidus, the equilibrium solid solubilitv has

a true maximum and the metastable

lower compositions.

extension continues to

The maximum was exceeded by rapid

solidification indicating that under extreme conditions

the significant deviations from local equilibrium can

be produced as shown in Chapter II.

It is interesting

to note another case where

local

equilibrium ceases to exist during solidification. Even

though the equilibrium

shape of a crystal may be faceted,

when originated during solidification the faceting is

usually a result of the growth kinetics.

Since such

shapes are not solutions to the differential

condition of local equilibrium

hold.

For instance, Glicksman

equations, the

at the interface does not

and Vold(32)

found faceting

during the freezing of Bi at small velocities,

but rounding

of the interface during melting at small growth rates;

this indicatesan

inconsistency with the condition of

local equilibrium

at the interface.

III.3

Steady-State Binary Solidification

Of the various experimental and theoretical methods

of dealing with solidification the steady-state planefront condition is an exceptionally

useful one.

We impose

a velocity V on the system and assume that after an initial

57-

transient the temperature and composition profiles and

the position of the interface will move with the

velocity V.

solid C

C

Under these conditions the composition of the

must be equal to the alloy's overall composition

0

C

Because C

= C

"diffusionless"

=

(3.11)

C

the process has some aspects of

solidification,

that there will be a diffusional

but it is highly likely

layer ahead of the inter-

face and the composition of liquid at the interface CL will

differ from C .

Under steady-state conditions this layer

remains unchanged with time and may be hard to detect.

It

will have a thickness of order DL/V, or less than 11 when

V exceeds 1 cm/sec.(33).

A study of steady-state solidification thus permits

us to fix V and C

and if we determine experimentally

the

value of T and CL at the interface we would be evaluating

the response functions. The functions although evaluated

by a steady-state experiment should be universally valid

for other geometries

state experiment

in that system.

If in a non-steady

the interface found itself with the same

value of T and CL as found in the steady-state experiment,

it should respond with the same V and C s .

Figure 3.2 shows Figure 1.7 redrawn for purposes

of steady-state

solidification.

The horizontal

line

58

represents the alloy composition

that is equal to C s .

The possible values of CL are those that lie on the

horizontal line but within the curve OABEP appropriate

The OABEP curves are given for the

for that temperature.

various temperatures, each representing a temperature

lying within three distinct regions of the phase diagram

given in Figure 3.3. Let us now examine steady-state

solidification

of an alloy of composition C