STATISTICAL VARIATIONS IN THE LAP-JOINT STRENGTH CIF METAL-I3CNIDING ADHESIVES AT ELEVATED TEMPERATURES

advertisement

AGRICULTURE ROOM

STATISTICAL VARIATIONS IN THE

•

LAP-JOINT STRENGTH CIF

METAL-I3CNIDING ADHESIVES AT

ELEVATED TEMPERATURES

February 1961

No. 1880

1

ibis Report Is One of a Series

'sued In Cooperation with the

ANC- 23 PANEL ON COMPOSITE CONSTRUCTION

i-OR FLIGHT VEHICLES

rf the Departments of the

#112 FORCE, NAVY, AND COMMERCE

FOREST PRODUCTS LABORATORY

MADISON 5. WISCONSIN UNITED STATES DEPARTMENT OF AGRICULTURE

FOREST SERVICE

n *operation with the University of Wisconsin

STATISTICAL VARIATIONS IN THE LAP-JOINT STRENGTH

,2

OF METAL-BONDING ADHESIVES AT ELEVATED TEMPERATURES-' —

By

EICKNER, Engineer

and

W. Z. OLSON, Chemist

H. W.

Forest Products Laboratory, Forest Service

U. S. Department of Agriculture

3

Summary

A statistical study was made to determine the sources and degree of variability in strength

obtained in elevated temperature tests of adhesive-bonded, lap-joint specimens of

corrosion-resisting steel. Four representative adhesives were included. Fixed effects

that were evaluated included operators, presses, and press-by-operator interaction;

random effects evaluated included days, bonding runs, and cleaning runs.

The coefficient of variation for the different adhesives, including variability introduced

by the fixed and random effects, ranged from 4.7 to 19.7 percent. There was some

indication in the bonds made with the adhesive showing the greatest degree of variability

that the fluid used in lubricating the specimen slitting saw may have penetrated the bond

line.

The significance of the fixed and random effects in contributing to joint strength variations was obtained by computing analysis of variance and components of variance from

the individual joint strength data. The press variable had a significant effect with all,

four adhesives studied, but the operator and the effect of different days on the work of

an operator was significant with only one adhesive.

The press-by-operator interaction had a highly significant effect with three of the four

adhesives as did cleaning rims and bonding runs. However in each case, different combinations of adhesives were involved.

-This

—This report is one of a series (ANC-23, Item 57-6) prepared and distributed by the

Forest Products Laboratory under U. S. Navy, Bureau of Aeronautics Order Nos.

NAer 01898 and 01974 and U.S. Air Force Contract No. DO 33(616)58-1. Results

here reported are preliminary and may be revised as additional data become available.

0. Yandle, Statistician, Forest Products Laboratory, aided in establishing the experimental design and made the statistical analysis of results of this investigation.

aintained at Madison, Wis. , in cooperation with the University of Wisconsin.

LD.

•

__/v1

3

Report No. 1880

Introduction

•

Adhesive bonding is finding wider application in the fabrication of flight vehicles in

which a large part of this bonding is done to corrosion-resisting steel alloys. These

bonds may be subjected in use to a wide range of temperature conditions, but the

strength properties are usually lowest at elevated temperatures. As much of the critical stressing of the bonds may occur when exposed to the elevated temperatures, it

is necessary that the bond strength at these temperatures be reliably maintained above

a minimum level. Completely satisfactory nondestructive test methods have not been

developed for the inspection of bonded joints, and therefore it is necessary to maintain

quality by rigid control of the bonding variables. Even with good control of the bonding

conditions, the coefficient of variation for the lap joint strength of bonded metal joints

may range normally from 6.4 to 16.2 percent.

It is virtually impossible to devise a single study that is practical, economical, and can

statistically investigate all the bonding variables which may influence the level of joint

strength. For this reason it was planned that this present study would be limited to a

determination of the strength variability obtained for bonded lap joints within test panels,

between test panels, between bonding runs, between surface treatment runs, and between

different operators and pressing equipment. Statistical design of the study was planned

so that the results can be analyzed and the degree of variability assigned to the various

influencing factors.

To limit the number of specimens, tests were made on only four adhesives using one

type of specimen, a standard overlap specimen of Type 301 corrosion-resisting steel.

This type of steel is frequently used in the fabrication of flight vehicle parts where

good: strength characteristics are required at elevated temperatures. The adhesives selected were also representative of types which might be used for bonding corrosion-resisting steel subjected in use to elevated temperature conditions of

300° F. and higher.

Procedure

Experimental Design

This study was so designed that the significance of the strength variability contributed

by the use of different operators, pressing equipment, cleaning runs, and bonding runs

on each of several days could be determined.

Three operators, each experienced in the use of metal-bonding adhesives, bonded

panels with each of the adhesive systems. Three presses--(1) an electrically heated

press with 9- by 9-inch platens, (2) a steam-heated press with 14- by 14-inch platens,

and (3) the same press with an oil-filled steel bladder laid over the panel to obtain

fluid pressure--were used by each operator in applying heat and curing pressure to

panels.

To also determine what effect might be obtained from different cleaning and bonding

runs by each of the operators on different days, three bonding runs were made by each

_Eickner,

Bickn er, H.W. General Survey of Data on the Reliability of Metal-Bonding Processes.

Forest Products Laboratory Report No. 1862. 1957.

Report No. 1880

-2-

•

•

of three operators on each of 3 days. Three separate cleaning runs with separate

fresh patches of solution prepared for each cleaning run were also represented by each

of the bonding runs. However, to limit the number of test panels required, there was

not a complete replication of panels by operators, by presses, by days, by bonding runs,

and by cleaning runs; instead, with each adhesive 27 test panels, 9 on each of 3 days,

were prepared by each operator, using the 3- by 3-repeating Latin Square arrangement

shown in table 1.

The nine panels prepared each day thus represented the results for three presses,

three bonding runs, and three cleaning runs. The different operators, however, were

not able, because of equipment and time limitations, to prepare the panels on the three

same days. Therefore the days-within-operator effect is statistically confounded.

Adhesives

The adhesives used in this study were:

(1)

(2)

(3)

(4)

Adhesive 59 (acrylonitrile-phenolic primer and film).

Adhesive 61 (epoxy-phenolic film).

Adhesive 63 (epoxy-phenolic film used with liquid primer).

Adhesive 64 (epoxy-phenolic film).

Fresh adhesive samples were obtained from the manufacturers for use in these tests.

The liquid adhesive components and Adhesive 59 film were stored at 40 °F. The other

films were stored at 0° F. as recommended by their manufacturers. The study with

each adhesive was usually completed within a storage period of 1 month.

Before opening of the cans of liquid adhesive components for use, the samples were allowed to come to room temperature. This was done to prevent condensation of moisture

within the cold samples. Samples of the film adhesives were partially warmed by placing them in the 40° F. condition prior to stripping off the protective parting film at

room conditions.

Type and Number of Panels

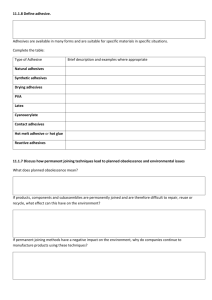

Lap-joint test panels (fig. 1) were prepared with each of the four adhesives by bonding

together two 4- by 9-inch pieces of 0.063-inch Type 301, 1/2 hard, 2D finish, corrosion-resisting steel (Specification MIL-S-5059 (ASG)), with a 1/2-inch overlap. A

total of 81 panels, 27 by each of 3 operators, were prepared with each adhesive.

Preparation of Panels

Corrosion-resisting Type 301 steel sheets (0. 063-inch) were cut to the size (4 by 9 inch)

required for the test panels by using a sheetmetal power clipper. The bonding edge of

each clipped piece was milled smooth to remove the burr that resulted from the clipping

operation. These milled 4- by 9-inch pieces were used in preparing the lap-joint panels

with Adhesives 63 and 64.

•

It was found desirable, however, as described under "Cutting and Testing of Specimens,"

to use preslotted 4- by 9-inch pieces in preparing panels with Adhesives 59 and 61.

Report No. 1880

-3-

Seven 3/32-inch-wide kerfs (fig. 1) were made in each milled piece so that it would not

be necessary, after bonding the overlapped pieces, to saw through the bonded area.

This made it possible to cut the specimens without the use of a coolant which might possibly affect the bond. The burrs at the edges of the kerfs were removed with a small

portable grinding wheel.

Cleaning of the Metal. --Letter markings and excessive oil were removed from the

steel pieces by wiping with a cloth saturated with acetone. Each piece was subjected

to additional cleaning by vapor degreasing in stabilized trichloroethylene using a small

commercial vapor degreaser. The steel pieces then were degreased for 5 minutes at

180° F. in a 6-ounce-per-gallon solution of a commercial alkaline cleaner. After degreasing the pieces were etched for 10 minutes at 150° F. in a solution consisting of:

10 parts by volume of concentrated sulfuric acid

(specific gravity, 1.85)

0.5 parts of a wetting and detergent agent for use with acid solutions

89.5 parts distilled water

The pieces were rinsed with distilled water, then immersed for 10 minutes at room

temperature in a solution consisting of:

10 parts by volume of concentrated nitric acid

(specific gravity, 1.42)

2 parts concentrated (60 percent) hydrofluoric acid

88 parts distilled water

After a final rinse with distilled water, the metal pieces were force-dried by air for

30 minutes at 110° F. The metal pieces were either bonded or prime-coated within 3

hours after cleaning. Fresh batches of chemical solutions were prepared for each of the

cleaning runs for groups of nine test panels as described under "Experimental Design."

Bonding Conditions. --The 81 panels prepared with each of the adhesives were bonded,

as precisely as possible, under the conditions listed in table 2. Each of the 81 panels,

however, represented bonding obtained by different operators, presses, cleaning, and

bonding runs on each of several days as outlined under "Experimental Design."

There was no temperature or humidity control of the rooms within which the bonding

was done. The bonding with a particular adhesive was done within a 3-week period and

therefore conditions during this period should be fairly constant. This lack of control

of room conditions, however, may be a factor contributing to variability in day-to-day

bonding. The bonding was also done by each operator in sequence. Each operator completed his bonding with a particular adhesive before the next operator started. This lack

of randomization may have an influence on the variability associated with operators.

Cutting and Testing of Specimens

Each bonded panel was cut into six 1-inch-wide test specimens (fig. 1). The panels prepared with Adhesives 63 and 64 were not preslotted before bonding, and these panels

were cut into individual specimens with the multiple metal slitting saws shown in figure

2. The saws were each 4 inches in diameter and cut a kerf 3/32 inch wide. A wateremulsion oil cutting fluid was used in cutting the panels prepared withAdhesive 63.

Fluid was wiped from the specimens immediately after they were sawn. This method

of cutting produced smooth cuts with practically no vibration or heating.

Report No. 1880

-4-

•

•

Meanwhile work in another experiment indicated that, for some adhesives, the wateremulsion oil might penetrate and deteriorate adhesive bonds. Therefore panels bonded

with Adhesive 63 were mill cut using only water as a lubricant. Panels bonded with

Adhesives 59 and 61 were prepared with preslotted panels (fig. 1) so that the only cutting necessary after bonding was done on the outer ends with a metal-cutting band saw,

used without lubricant. A jig was used to hold the panel during this cutting operation

to reduce vibration.

Only alternate specimens were selected from each panel for test. Specimens bonded

with Adhesives 61, 63, and 64 were tested at 500° F. , and specimens bonded with

Adhesive 59 were tested at 300° F. These tensile shear tests were made in accordance

with the general provisions of Military Specification MIL-A-5090B.

Templin-type wedge grips were enclosed in a large Hevi-Duty oven heated by electrical

resistance heaters. Air was circulated by fans within the oven, and temperature was

controlled bya Brown Electronikcontroller for rapid heating and close control (±2° F.)

of the test temperature. The specimen was placed in the grips so that the jaw ends of

the grips were 2 inches from the edge of the overlap. Thermocouples were placed on

the faces of the lap area of the specimen to indicate the specimen temperature, and a

load was applied in tension to the ends of the specimen with a universal-type hydraulic

testing machine. A loading rate of 1,400 pounds per square inch per minute was applied

10 minutes after the specimen reached the testing temperature. Failing loads were read

to the nearest 5 pounds. Figure 3 shows the test machine, oven, controller, and potentiometer used. The same equipment was used by the same operator in making all of the

tests.

The width and length of the test areas of all specimens were measured to the nearest

0.01 inch prior to test, and the failing strength values in pounds per square inch were

computed on the basis of these measured areas. The type and magnitudes of bond line

failures were also noted.

Results

The individual strength test results obtained at 300° or' 500° F. on the corrosionresistant steel lap joint bonds prepared with four adhesive systems are given in tables

3, 4, 5, and 6. Results are grouped together for the three tests made from each panel

prepared by a particular operator, in a given press, day, bonding run, or cleaning run.

The statistical analysis of variance for these data, and the grand average, standard

deviation, and coefficient of variation for the data obtained with each adhesive are given

in tables 7, 8, 9, and 10. The analysis of variance for these data follows standard

statistical practice except for checking the significance of the day-within-operator effect, which was statistically confounded. Here an approximate method of fitting a chi

square distribution to the distribution of the mean square was used. 5

The components of variance for the four random variables--days within operators,

bonding runs within days within operators, cleaning runs within days within operators,

..53. L. Crump. The Present Status of Variance Component Analysis. Biometrics,

1(7):1-16. March 1951.

Report No. 1880

-5-

and residual random error obtained from the studies with the four adhesives --are computed and summarized in the Appendix.

•

Adhesive 59

The average lap joint strength for the Adhesive 59 bonds (table 7) tested at 300° F. was

918 pounds per square inch with a coefficient of variation of 12 percent. The betweenpanel variance was significant at the 1 percent level, indicating that much of the variability was caused by the random and fixed effects under study. Effects of presses,

bonding runs within days within operators, and cleaning runs within days within operators

were significant at the 1 percent level.

The analysis of the components of variance for the random effects indicated that the

effects of bonded runs within days within operators and cleaning runs within days within

operators each contributed about 40 percent of the total random variation (Appendix).

Adhesive 61

For the Adhesive 61 bonds (table 8), the average lap joint strength at 500° F. was 1,962

pounds per square inch with a coefficient of variation of 5.9 percent. The betweenpanel variation was significant at the 1 percent level. The random effect, cleaning

runs within days within operators, and the fixed effects, presses and presses by operators, were significant at the 1 percent level. The cleaning runs -within-days-withinoperators effect contributed 57 percent of the random variability (Appendix).

Adhesive 63

For the Adhesive 63 bonds (table 9) the average lap joint strength at 500° F. was 931

pounds per square inch, with an average coefficient of variation of 19.7 percent. This

strength is considerably lower than stated for this condition by the manufacturer, and

this coefficient of variation is large.

It is believed that some of this lower strength and variability may have resulted

from penetration of the lubricating fluid into the bond line during the cutting of the

specimens. The between-panel variability, however, was highly significant to the

1 percent level. This indicated that much of the variability was contributed by the random

and fixed sources and not by the residual experimental error between specimens, which

might be contributed by an uncontrolled factor such as specimen cutting technique. The

general level of strength, however, is considerably lower than obtained in other studies

with this adhesive system.

The press -by-operator interaction and bonding runs -within-days -within-operators effects were significant at the 1 percent level, and the operators, presses, and days-withinoperators effects were significant at the 5 percent level. Further analysis indicated

that 63 percent of the random variability was contributed by the day-within-operators

effect (Appendix).

•

Report No. 1880

-6-

•

Adhesive 64

For Adhesive 64 (table 10) the average lap joint strength at 500° F. was 1,696 pounds

per square inch with a coefficient of variation of 4.7 percent. This is a low coefficient

of variation for bonded joints, and most of this variability was caused between panels by

the random and fixed sources being evaluated.

The variations resulting from the fixed and random effects were significant at the 1 percent level, except for the days within operators, which was not significant when checked

by the modified chi square method, _5 and the operator effects, which were not significant.

The analysis of the components of variance for the random effect again indicated that

most of the random variability was contributed by the days-within-operator effect (Appendix).

Conclusion

With all four adhesives studied, the press variable was found to have a highly significant

effect. Only with Adhesive 63 was the operator variable found to be significant. The

press-by-operator interaction, however, was highly significant for Adhesives 61, 63,

and 64; for cleaning runs involving Adhesives 59, 61; and 64; and for bonding runs involving Adhesives 59, 63, and 64. The days-within-operators effect was significant

with only one of the adhesives.

Appendix

Components of Variance

The components of variance for the four random variables --days -within-operators,

bonding runs -within-days -within-operators , cleaning runs -within-days -within-operators ,

and residual--were also calculated after first determining the terms comprising the

mean square expectation for each source of variation. The method used was that conventionally stated in statistical texts, including "Statistical Theory in Research."_

These expectations of total mean square for each random variable are:

Source

Days /operators

Bonding runs/days/operators

Cleaning runs/days/operators

Residual

o- e 2

(•e !

o-b `

o• d 2

Degrees of freedom

Mean Square Expectation

2

2

6

o-,2 9o- 1,2 + 9o- e + 27o- d2

9

2

182 cr+

ecr b

2

182

+ 9a c

quee2

192

= variance for residual

= variance for cleaning runs/days/operators

= variance for bonding runs/days/operators

= variance for days/operators

6

_Anderson, R. L. , and Bancroft, T. A. Statistical Theory in Research. McGraw Hill,

New York, 1952.

Report No. 1880

-7-

By equating these mean square expectations to the corresponding mean square estimates

in the analysis of variance (tables 7, 8, 9, and 10), it was possible to compute an estimate of the variance for each of the four random variables.

Percent of the total random variability contributed by each of the random factors was

obtained from the weighted ratio of cr e2 /total number of tests (243), 0- c 2 /number of

cleaning runs (27), crb /number of bonding runs (27), and cr d2 /number of days (9) to

the sum of these values. The calculations were as follows:

Adhesive 59

E(MS)

; Degrees: Mean

: of : square

:freedom:

Sources of variation

Operators

2

: 41, 138 :

Presses

2

: 612, 312

Operators/presses

4

:

Days /operators

6

: 13,241 : cre 2 + 9' b2+ ?,o- c2 27o-d2

6, 877 :

: 18

16, 237 : v e 2 + 917 b2

Cleaning runs/days/operators : 18

: 15, 994: cr e2 + 90-c 2

Bonding runs/days/operators

Residual

: 192

Total

: 242

cre2 = 4, 812

o-c 2 = (15, 994 - 4, 812)/9 = 1, 242

crb 2 = (16,237 - 4,812)/9 = 1,269

°d2 = (13,241 - 11,182 - 11,426

Var (y... ) = (rd2

9

b2 +

9

e2

27

4,812 : o-e

z

: 12,057 :

7

4,812)/27 = 0—

o-e 2

243

= 0 + 1' 269 + 1' 242 + 4' 812

27

27

243

= 0 + 47.0 + 46." + 19.8

= 112.8 (total random variability)

0

x 100 = 0 percent of random variability attributed to days.

112. 8

7A value of 0 is assigned when the computed value for the component of variance is negative.

Report No. 1880

-8-

•

•

47 x 100 = 41.7 percent of random variability attributed to bonding runs.

112.8

46

x 100 = 40.8 percent of random variability attributed to cleaning runs.

112.8

19.8

x 100 = 17.5 percent of random variability attributed to residual.

112.8

Adhesive 61

Source of variation

E(MS)

:Degrees: Mean

: of : square

:freedom:

Operators

2

: 61,526 :

Presses

2

: 85,092 :

Operators/presses

4

: 39,435 :

Days/operators

6

: 30,120 : a- e 2 + 9crc

e

re 2+ 9crb2

Bonding runs/days/operators

:

18

: 14,240

Cleaning runs/days/operators

:

18

2 9 2

: 29,309 : (r e + trc

Residual

: 192

Total

re

ma c'

: 242

2

2

9,787 : o-e2

13,614 :

= 9,787

= (29, 309 - 9, 787)/9 = 19,522/9 = 2,169

= (14,240 - 9,787)/9 = 4,453/9 = 495

vd 2

= (30, 120 - 19,522 - 4,453 - 9, 787) = 01

Var (y... • ) = 0- e + 03 2 + crc 2 + cre2

27

243

27

9

495

27

9, 787

2, 169

+ '

243

27

=0 v — '

= 0 + 18.3 + 80.3 + 40.3

= 138.9 (Total random variability)

•

0

x 100 = 0 percent of random variability attributed to days.

138.9

Report No. 1880

-9-

+ 9o- b 2 + 270-2

18.3

x 100 = 13.2 percent of random variability attributed to bonding runs.

138.9

•

80.3

x 100 = 57.8 percent of random variability attributed to cleaning runs.

138.9

40.3

x 100 = 29.0 percent of random variability attributed to residual.

138.9

Adhesive 63

Source of variation

:Degrees: Mean

of

•

: square

:freedom:

E(MS)

Operators

2

: 731,508

Presses

2

: 91,848 :

Operators/presses

4

: 159,938

Days/operators

6

: 140,376 : c • e 2 + 9ir c 2 + 9(rb

Bonding runs/days/operators : 18

Cleaning runs/days/operators : 18

Residual

: 192

Total

: 242

cee 2

2

2

+ 27a- d

51,907 : ae 2 + 90' b2

: 15,557 :

19,804

Te l

+ 9a c

2

a-e2

: 33,659 :

,

= 19,804

Tc 2 = (15, 557 - 19, 804)/9 = 07

•

= (51,907 - 19,804)/9 = 32,103/27 = 3,567

cr d 2 = (140,376 - 32,103 - 19,804)/27 = 3,277

2

Var (y...) = 2151- +

9

_ 3,27

9

2

2+

27

+

27

2

243

3,567

19,804

27

243

+ - + 0 +

= 364.1 + 132.1 + 0 + 81.5

= 577.7 (total random variability)

364.1

577

. 7 x 100 = 63.0 percent of random variability attributed to days.

132.1

x 100 = 22.9 percent of random variability attributed to bonding runs.

577.7

Report No. 1880

-10-

•

•

0

x 100 = 0 percent of random variability attributed to cleaning runs.

577.7

81.5

577

. 7 x 100 = 14.1 percent of random variability attributed to residual.

Adhesive 64

•

•

E(MS)

:Degrees: Mean :

: square

of

:freedom:

Source of variation

Operators

2

: 43,227 :

Presses

2

: 33,802 :

Operators/presses

4

14,773 :

Days/operators

6

40,068 : cr e 2 +

Bonding runs/days/operators 18

Cleaning runs/days/operators

18

Residual

Total

8, 480: cr

e2

c

2 + 9vb2 + 27o- d 2

+ 9o- b2

11,734 : cr e2 + 90-c2

: 192

3,870 :

: 242

6,448 :

0

e2

cre2 = 3,870

2 = (11, 734 - 3,870)/9 = 7,864/9 = 874

2

0b = (8,480 - 3,870)/9 = 4,610/9 = 512

2

=(40,068 - 7,864 - 4,610 - 3,870)/27 = 879

cr d

2 + Le_2

z

Lk +

Var (y.., ) = Ir d

243

27

27

9

cr c

=

9

879

+

512

27

874 + 3,870

243

27

= 97.7 + 19.0 + 32.4 + 15.9

= 165.0 (total random variability)

97.7

x 100 = 59.2 percent of random variability attributed to days.

165

19.0 x 100 = 11.5 percent of random variability attributed to bonding runs.

165

S

32.4 x 100 = 19.7 percent of random variability attributed to cleaning runs.

165

15.9

x 100 = 9.

165

Report No. 1880

6

percent of random variability attributed to residual.

Table 1.--Schedule of partial replication of test panels for 3 operators,

3 presses, 3 cleaning runs, and 3 bonding runs on each of 3

days

Operator :

1

Day

:

1

1 : : Press

: Bonding run: Press 1—• : Press 2—

1

1

2

3

A

C

B

:

:

:

B

A

C

C

B

A

:

4

5

6

F

D

E

:

:

:

D

E

F

E

F

D

I

G

H

G

H

I

J

K

L

L

J

K

:

2

2

:

:

:

:

3

:

:

:

7

8

9

H

I

G

:

4

:

:

10

11

12

K

L

J

13

14

15

M

0

0

N

N

M

N

M

0

5

6

:

16

17

18

R

P

Q

Q

R

P

P

Q

R

7

:

19

20

21

U

T

S

T

S

U

S

U

T

8

:

22

23

24

W

V

X

V

X

W

X

W

V

:

3

:

:

:

9

:

25

26

27

:

:

:

Y

Z

g

:

Z

:

IT

:

Y

:

•

31

g

Y

Z

-Letters indicate the different cleaning runs used in preparing a test

panel with each of the operators, day, bonding run, and press variations.

Report No. 1880

•

•

Table 2.--Bonding conditions for preparation of test panels

Adhesive

59

61

63

64

:

: Application

: of adhesive

:

Curing :

:Drying time:

:

:temperature:

.•

Air :Oven:

:

dry : dry:

:

: Hr. : Min.:

°F.

Min.

P.s.i.

: One thin spray : 18 : 15 :

: coat of primer :

: (at :

: to each surface.:

: 180°:

: F.):

: After air and :

.

: ovendrying, the:

film was at-

:

:

:

: tached to one :

: surface.

:

350

60

100

: One layer of

: film.

330

30

20

2

: One thin coat of: 18 : 60 : -540 diluted primer!:

: (at :

: was sprayed on :

: 150°:

each surface. :

: F.) :

After air dry- :

ing of primer, :

the film was :

attached to one:

: surface and

: precured along :

with the primer:

: coating.

2

-30

2

-100

45

25

: One layer of

: film.

: None: None:

: None: None:

•

Curing : Pressure

during

time

:

.

cure

1

:

:

350

-Equal amount of primer and thinner mixed by weight.

2Tanels prepared with this adhesive were in the press at a platen temperature of

200° F. and a pressure of about 6 pounds per square inch. Pressure was increased gradually to full pressure in 12 minutes. Temperature was increased

to the final cure temperature in 15 to 30 minutes. Panels were then given

a cure for 30 minutes.

Report No. 1880

•

•

CU

00

ol

,4

W

M

e

1:14

.

O

1 1

•4

0

o4

• ..

•4

•

O.

03

04

..

•

en

C)

04 el r... ul 03 00 cm 4 C)

is- Cm ..../ CD CD r- CD CM C4.4

C)

cm C) ml CD .4 C) N. 01 CO C4 0%

s .4 cm

ul r...

.4 VD 0% 00 OD OD Cas

.

0) 0%

CD CM CD .4 cm oo C)

C)

.4 a CD CD CD CD CD Cm CD CD CD ON Cm 00 r- CD

.

.

es •••

es

.

es

a et

etooftneen

.

•.-1

.-4

1. r r4

.-I

1-4

,-4

,

rA ' -I

-I ,4 r4 .--II

o-1 .4 .-4 .--I

.. .. ..

q. WW r. d .

••

•• •• .• •• s • •• •• ••

VD ,t C4 CD CD 4 VD 03 C4

. C4 00 77

e4 cD ......t 00 V) v0 C) .41. VD

C) WO CO VD .4

.4 CD 0.- CM 4 V, en CO 4

0 0 N C. c1 u10 u10

CA rs CD ON u11- .4 .1 00

CA C) Cm C) OD CM r4 op cD

e4 cn CD 00 r- CD C) C)•• cn

e4 cm Cn CD C) CD .4 cm CD .

.

.

ft

••

in

.

.

•-i

.-1

il

,4

r4 VI 1-- ul C4 ,-4 .4 rA iil C4

e4 r4 on on ..t Ul C4 rn CD on

7

.. .. ..

m

OS MI

0,

r4 ,.I r-I r4

In1

r4

.. ... .. .. .. .. .. .. ..

r-I

..1

r.4

••

••

-•

•••

r•

••

.-I o-I

SI

••

n I

•• .. IR

.. .

. . .

.

.

r4

ir4 ,4 r4

rA

o-C 1-1

.-4.

,4 r4 1..4

p4

O

7.a)

•• .. •• .. .. •• •• - - ..•• r4

4

0)

CO

4

W

o

O

eh CO 4% •n 4%

r4 1.4 v4 r4 rA v4

04

4.

GS

•n ••n

4%

•

rA r4

.

•S

(0

C0

Ti▪

.

W

M

• . • ••• ..•

00

r4

0

,b

v4

0

0

.. .. .. ..

r4 y4

r4

r4

1-4

,4

r4

1J

',IA '1.1 2)) IA I CI cCI :g gg

C) CA CD r4 CM 1-.. CD 00 r4

e4 e4 01 C4 CV . . .1" cm -1 CD

0 ol r-. r- ...1. ir- cl ri CV

CD C) CD cD CD cD cm CD CDCl. Cm CD 00 a) CD 00 cDnCm

.

r4

CO

..4 ca N 0 VD CD CD OD CD

MD 4 03 '.0 0 4 N 0 -4

a)

r.... 01 e4 vD e-1 03 Ul 00 cm 00 CD on '4 V/ V/ CN CD CC cn ;1 4.1

r4 03 00 ol CD ol c4 r4

cm LOCH ON

CINC1.-1 Cs1 In s4' r- as .-4 e-i C0014 c0

r- 0, 4 al° esli 0.• 0% c-- sr,

C) 00 00 03 OD Ch CO OD O n ID

ch r.. C) 03 ON C) CD ON cm ch cm OD Ch OD ch cn co 03 cD cm CD

g

.. a.

01 ....t

.

a) 04.

..1 r.4

r4

v4 r4

,4

44c)

..•• ••.

c•-)

C4 '04 00 V) VD VD OD -4

VD c•4 .1. c4 -7 CO '0 co '0

C) Ma e4 '.O .4 Oc4 C4 CO

• 4

as 01 01 CD 00 rs VD CD C4

r4 F.,

.4 MD .4 Cm

a do

O

W

0

CO 7

..

04

r4

a)

m

O

.

I

Cu

co

a

a)

•

AI

• •

.-4

• • •

o

r4

••

r4

al

..

.. .•

..

..

..

I>

•• •• •• •• GO

v

r.4

.

W

to

•4

14

W.

O

W

.47

••

r.4 e-4

44.

r4

.•

$4

.1.1

• •

• •

'O 'D c) VD VD mD mD CD mD

.. CD C) ...t VD .4

cD C4 r4 01 01 mD ...1 V1 ntr4 r4 cm 01 V) a 03 0, -4

C) 00 oa 00 Cs cm oa CO CDO.

Cn Ch CD GO Ch CD CD Ch cm

•• •• •• •• •• •• •• •• •• ••

ca

. .

••••1 ,•I

.

•••I

• •

• .

• •

• •

44

• •

1.1 gg .14. g 2 A gi g g 2

4)

.4 CM 03 00 00 00 04 00 00

.

0

r4

,400 C4 C) .7

.

w

1:4

Ii

4. DO GO .. .. .. ..

ul r4 00 V) .4 CI Cs. CD .4

Cm CO 03 03 Ch Ch 03 ch C,

• •

W

43

al

ua 4 ma 00 4 00 m) st m) 1)

cm

el r- r- r- 1.1 CO CD CM

4..)

cD CD 00 03 cn cm 00 02 00

vD v)

r-I r--1 .4

1-4

m

a el.

,4 1.4

r4

co c4 OD CD C4 C7 . ..t

.

0A op co 0•• 04.o••0.%

a)

00 Cm 00 03 Cm CA 0% 00030'

••

04 4 CD 4 CD a0 7 CD 4

.4 cm ....t mo .....t 04 00 .4 CO

•

0

vl 03 4

03 CA r, Cm CD. CO 0% 05

.. .. .. .. ..

44

0

C)

.

r4

r4

•••4

1..1

• ..

.

N

W

O

r• O

•

.

.

0

.

0 n0 rn N. W100.400 CO C) 00CD. 00 CA Cm .4.CA ch

.

W

03

.0

v.,

v4 v4

•• ••

m4

•d

0

'8

0c.)

•• •• ••

•

VD C) CD

CD CD 03 o0 Ca CV

ol 01 el cD /4 4. n. cm ul

CD•• Ch CD0 .4••Ch CA CM CO 1n44.

mD C) C4 ,t C) OD C4 .4 04 VD CD c0 C4 C) ...., CD 00 .1

0.4 vD.1cp Ul 1....

C4 v0C) ul ul c4ol C4 CO

•

a)0 ..01c4......t

i.

CM CD ON cm r- .-4 CD CD cn

r4 CD r.4 Ch CD CD CD Ch cm o

$4

la

0

..

A.

•I

..

.•

ra

N

a)

w

.1O

41

r4

o

1.1.

• •

,-.4 tva o. r.-- 7 (NI o•n 0.1 Lin 7

VI 01 WD rA 01 U1 01 V) Cm CD

rn t,1 . .t ,..0 ,I•01 I-1 0, so o cr. C4 v4 1-... ra

. . o a, In

cn r03

OD cm r- 00 00 00 03 00r, 03

00 r- CO 03 00 00 03 CO

0 "ti

MO

Ch (N

in .°'

4n

a 00

c•s

;1 oo

ul 4

r-- 1. o

, .-4

..

oa oa op I--00 r

CO

oa r..e

0

w

P4

W

.. .. .. .. .. .. .. " .. .. .4 c0 C4 CD vO CO c0 C4 .4

o -.1- csi

CD .4 4 CD c4 CD CD C7 CD

..4. 1- 01

on vD el 04 .1. N 01 CD

....t CD VD r-. C) e4 mD r- ol

el COu1

03 03 Cm OD 03 r... 00 N 00

00 CD 0, 03 00 00 00 N- 03

OD 00 OD OD 00 03 03 00 03

el3

4

o

ca

O

54

04

a)

0

-I

•

ca

C0

.

04

0 ,-0 -.7 .4 0

CM C) 01 N 0

.-I

>

•• •• •• •• •• •• •• •• •• .•

..

.1

Ai

.4

.

g 5; I 8 !: 8 g g .1'4

al

0

0

7.

O

r4

••

•• •• •• •• •• •• •• •• •• ••

•• •• •• •• •• •• •• •• •• ••

94

.

CD -.7 CD OD 00 C4 C4 CD -I

....1 .0 c4 .1 ,T r-I 00 C0'0

N.. 00 03 r'S 03 cm r- 00 00

.../. mD c4 CD C) C4 4 VD c4

r4 cm ..../- vD vD CA r4 .0 vD

00 co 00 OD r- CA 00 03 h..

0.

1

..

.•

O

I

O 0

03

0

W C4

,-1

,4 r4

CD

Report No. 1880

. . 1.

.. .. .. .. .. .. .. .. ..

00 N 00 N. 00 N 00

00000

A

1.1

C.) 0)

03 4

W 1-1

•

P1

P

• ••

•• •• ••

00

ai

0 s.

O.

..4

0 JO

VD VD 04 WD 04 04 03 OD C)

C4 r4 01 CM C4 04 4 00 CD

00 00 r- 00 OD 03 03 co rs..

OD ch N. CO 030'. 03 00 0D

..1

W

..

. .

00 CD CD C4 C) -I ..t ..t C4

ol rs. ul rn r4 C) ol

01

M

e

vi

0

0.

•IJ 0

a

IA

•• •• •• ••

r4 N

•• •• ••

• •

. • . • • •

M0

4.).. 0

to

0. VD r...

0 0

S4

ai

O CI)

14

01

W jj

14

cv cD .4 Cq ol --t orl ..0 r-. GO

ol . .1 WI 03 r... 03 cm

rA

$.4

r-I r-I r{ ri r-I r-I 1-4 ri

(.1

14

a) 0

00 4-1

07

a)

00 4-)

0 0

0

0 0

7 00.

-4

0

• • • • • •

Fn. • •

01

0-

• •

Ir.. Ch 03 ,C, 1...

o 0

1-i

. •

-..1 00 '.0 WD C) CD CD 00 C4

CA CD vD VD 00 CD Cr% 04 03

rs

0

41

.•

3-1 I-1

7 0-

.44

0

:.• P

CV 1,

-I. vI VD r-

Cm CD e4 N CD

N c4 c4 N c4

4-4 C4 C4 CA

4 4.1

4..1

o .1.3

00 4.1 CO

0 01 co

1. 1.4 .-4

V ,4

.

41

•

•

4J

W

W

•

0

00 ”4

id

•

W

CO

>

44

••

0/

0.1

•

0

C. tO

01

W

44

P4

•

•

4

N.

•

P4

co

•

N.

ea . •• •• so

W

al

P4

•

111

••

• ••

••

•• •• ••

•• •• •• •• •• •• •• . ••

a•

• • • • .•

C) C) C) CD 0 C) CD C) CD

an r4 1.4 cn 01 Ch Ul C) CO

0'. CT Ch Ch r4 CM OD Ch CAa

4 a A •• •n A •• •n

r4 r4 r4 r4 C4 r4 w4 r4 r4

CD CD C) 0 CD C) 0cr.

C) 0

CO 1/410 Ch Ch ul 01 ...7 rm

CA CD 0. CM C) CDAC)••

00 a

ODa

a, 4 0 •• ••

rg eg 1-4 r4 04 C4 CV rg r4

C) C) C) C) C) 0 0 CD 0

C) CV VD Ch %Co ul Ch 4 Ch

00 r4 C) 00 eg C) CD CM C)

4. a A ••

4 A a A

r4 CA Cg rg eg CV CV rV C4

•

W

O

:3 a i 51 2 2. gi gi

C) 00 03 Ch••

CDA

CD••ChaCha rg"

A A la

CI r4 r4 r4 e4 CA r4 r4 C4

•• •• •• •• •• •• •• •• •• ••

•• •• •• •• •• •• •• •• •• ••

••

•

•4

0

C)

w

W

••

•4 •• M. •• ••

ril

•

0)

C) 01 rm CD 01 01 I. C) 01 N Pm I. 01 rm 01 01 01 N. el r4 4.1

00

•• ,•••

•

hg

0/ 011. 01 N. C) 01 N. Oro

oo 00 rm rg U1 C) rm. rg OD

•

0 rg CV C) Ch C) CD CO c si v, ,4 ,i. 00 0 0, 0 60 ,t 0 4 e4

01

Cn

g

Ch CD OD 00 C) C) CD OD

r

CA CO CN 00 Ch

r g rg CD rg CD Ch CD 03 r gaCD

GO

C) r4 rg Ch•••CA

14

44•144•••n •• A

4. a O. a

•• 4

w •n a n.

4

•

II, VW on

0

r4 C4 r4 r4 CA C4 CV 1.4 CA r4 g

g Cg CA

r4 r g rg r4 rg

CV

C4 CA CA rA r4 CA Cl C4 C4 C4r

P4

0

..4

••

•

••••

P3

O

01

W

14

tI

••

C) C) C) C) 0 CD C) CD C)

CD C) C) 0 C) CD C) CD C)

a

eg Ch rm 4 01 V) CV 01 UN

el 03 Cl Ch rg 1-4 CD U1 00

el CA CD ...400 CM Cm

00

00 rA CD Ch r4 Ch Ch 00 00

W

4 A MI a a •n 4 a 1.

4 A a •• A •• •• •• Oh

Cl eg rg CV 1.4 r4 rg rgrg rg rg rg CV CI rg rg rghl

P4

111

01

W

•

r4

1

m

•

•• ••

• •

• •

•• •• •• •• •• •• •• •• •• ••

.

0)

M

0

14i

CD C) CD CD

51 5? 53 g 2 *AD 01 CO •.4

rm CD 00 00 CA Cm C) 00 r4

a a a a a a a a s

rg N rg rg rg rg CV vg CV

01:

.. .. .. ...

••

•• . . . •• •• •• •• ••

P>

•

•

M

•

04

•• •• •• •• •• •• •• •• •• ••

1 •1

•• •• •• •• •• ••

.

0 C) C) CD C) C) C) C3 CD

VD Ch C4 4) r4 VD VD .7 U1

o3 Ch CD rg CD cn 00 Ch rm

a 4 A 4 •• a IA a

rg rg CV eg Cs) rg r4 r4 r4

C) C) C) CD CD C) 0 0 C)

...5 Cl C) 0, CA CV CV eg 03

rg rg C) CD

CD r.4 1-1 00 CA

a • 4 a •• ft 4

NCI eV r4 r4 CA C4 C4 CA

.0

4-)

04

44

•• ” ••

i•+

J.J

Cl

W

0

0

0

cr)

4.1

OS

.4

O

0)

01

4

r4

li

P.

ei1

CV

0/

0

r4

O

Or

••

r4

0

0

rg

O

•• •• •• ••

•

44

•

W

04

....••

••

.

4

••

•4 ••

•• . . •• ••

•• •• e•

•• 41

••

..

••

114•47047 CT

•-I

•• ••••

•• •• ••

•• ••••

•• •• .1

••

••

••

••••

•• •• ••

•

.1

•

••

•• ••

••

••

.

51

2 53 g

i...1 2

03 CA 04 CD Ch Ch Ch

04

CV rA r4 r4 C4 CA r4 r-1 rA

0 an

•I1 a a •• •• ft

....••

••

••

rg rg eg eg

••

••

••

00 C) C) 00 Ch CO Ch CO Ch

• n • 4

a

•• • II 1 • n I • • • • •

0404C.4,11,41.40•1,1

.....

•• •• •• g• •• •• •• •• ••

••

••

••

•

0 0 0 0 0 0 0 0

a% 4 co U*1 C., CM 01 in o

CD C) C) CD C) CD C) CD CD

1•4 U1 VI CD 01 :4 C) Ch :4

03aCD

r4 0 00 0% cn cn Ch

a a a a a A a

C) C) CD CD CD C0 CD C) C)

03 CO Ul 01 OD eg 01 CD CO

Cn Ch CM 03 Ch C) Ch CM 00

a •• 4 A •• a 4 IR ••

1.4 r4 r4 r4 r4 CA r4 r4 r4

a a a

W

0

1.1

10

14

•• •• .•

. •• . ...41

. . •• ••

••

000000000

rm

r4 .7 03 ...7 ul ul 01 Ul

C) C) Cm ch co 00 rm

01 m00

A a A • II A •• a a

0 0 0 0 0 0 0 0 0

Ch 03 1 .... 01 01 CD 41 CO 01

Ch 03 C. 03 CD CD OD CA CM

A A •• 1111 A I. ft •• a

r4 TA r4 1.4 CA CI rA 1.4 r4

,41.1

41

•

014

•

••

0 0 0 0 0 0 0 0 0g

C) CD CD C) C) C0 C) C) C0

C) C) CD C) CD CD CD C) CD

01 4 1001 ul CD ul CO r Ch 4 ..r rA rm 01 rg CA V)

CD 41 r4 0.0 CA .1 CO 00 41

Cm 0 Cn Cr% CD Ch 03 C) CA

CM 03 Cn 00 00 00 03 03 00

t. 03 P. C.. r, Ch 00 0 m

4 a I. 11. A 4 A 4 a

• IA •• A A A. •n a A

IN 1111 •• A 4 A VI A MI

rg rg rg rg 444 444 1.4 CA Hrg rg rg rg 444 rg rg 1.4 rgrg N rg r4 N1.4 r4 04 r4

•

• ••

.

•

a v.

eta“

•• . •• . •• •• •• •• . e•

44

W

0

01 CD rm CD rm CD C4 01 0/ rm 01 rm rm rm CD 01 rm

M 0104

00 hg 01010001004 CD

CD

C.. 01 r4 rm ..7 41 CA 01 CD0%r4CD

U1 Ch CD Ul r g Ch %0 CD MN MN 00 r4 ../ 01 03

O

ch

ch 0% CA 03 OD CO CA CO C) C) Ch Ch Ch

LO

CM CO 00 00 CD CA 00 CD Ch Ch CAaeha0%

14

. 4. 4o

i•

a noi .4

4 .

in ao.4“.4141.4 44

4P

r•I r4 r4 rA CA r4

r..1 ro rA rA 1.4 r-1 r4 •••1 444

44•1 1.-4 1.4 1-1 N rl ri asl 1-4

114

t

'CS

0

•• •• O., •• •• •• •• •• •• ••

•• •• .10 •• •• •• •• •• ••

•• •• •• •• •• •• •• •• ef ••

••

4J

C0 C) C0 C) C) 0 C) CD C)

C) 01 47 c4 0 01 v) 01 01

rg r4 C) Ch r4 r4 CD CM r4

4•4414•61.4-••••

CI CV CV r4 C4 CA C4 1.4N

l•

et is

•

n7

..100 •• ..•• •• •• •• . . •• •• •• •• 0/

'4

0

CD C) CD <7

5R g 5R 5? CD

CD CD ,ci 0 0 0 c) 53 c)

44

0 0 0 0 0 0 0 0 0

01 rm C4 CA CD

rm

VD U1 VD 0, Ch 03 P,

•

.7

0)

an CO rm .7 00 rg

4.)

00

CD

C)

Ch 03 rg

h

Ch

CD

A

00

Ch

Ch

03

rg

g

C)

Cn

ra

r

,

g

O

Cn

CD

to

CD

CD

CD

C)

r

w

en

W

•n

••••

•n

•••••n

•••n

a .. a •• A •• A A a

4b...4“....ner.r“

•O4 04•

r4 CA r4 r•4 C4 C4 r4 r4 C4

r4 Cl . r4 CI r4 rA r4 r4 r4

r4 CA C4 CA C4 CA C4 CI CA

0>.14

•• •• ••

td

••• pi. •••

• •

•

1. ♦

W

O

1.4

JO

0

U-1

•• •• ••• •• •• •• ••

..

• • • • . •

C) C) CD CD C) C) 0 C) CD

rA Ch.00 r, r4 rm 01 e4 cn

CM CD 1"*. 0 cD OD co cm rm

asaaaaaaa

r4 C4 rA N CA r4 rA r4 04

OD 01 rg CD 04 rm Cm 0 c0

CA rg 04 03 CA 0 0 rg rg

44411144444

rg C4 eg rg rg CV CV CV C4

•

CV

• •

C) C) C0 0 CD (0 C0 CD C)

m4

0 04

. e ••

•• •• •• • • •• •0 • • . • 1111

a.

4%

4%

rg

r4

•• •• •• ••• •• n 11 •• ••

•• •• •• •• ••

es..

ro

sd

••

•

CV

C) C) 0 C) C) C) CD C) C)

hg

CD CD C) CD CD (0 C0 CD CD

,4) 01 ul .7 rg 01 01 00 VD

U1 in r. Nul N 0 01 01

•

U

MCA

CA CM CM '-4 Ch Ch 00 OD

0

al a •• •• •n •• A 0 dA

C°.n...t 01 'Cin a.:, 71•1 001, al 04

rg•

r4 Hr4 r4 CV r4 ..4 .-4 1.4

rg CV rg r4 r4 C4 CA r4 CA

P4

4

4-1

••

ea • • •• •• Of •• •• ••

C) 0 CD CD C) 0 C) 0 C)

N. ch 4 CD 01 V) C) U1 r,

C) CO Ch 1.4 Cl OD CM CA

•• al •• A A a ill• a PI

rg Cl rg rg 04 CA rg rg rgvg

•

in

0

r4 r4 rg rg CV N

r4 CA r4 HCV N 1.4 r4 C4 rA 1.4 CA r4 r4 CA r4 r4 r4 1.4H

•,. ••

,/

W

r4

•

,•1

es es

is. 01 0 CD CD C7 r m CD r, 0101s

r, C) r, 0 01 01 01 CD C) ...? Ors 01 el c7 rm

Ul .0 es r-1 .-4

ON Ul r, rl 4 MD 4 Mm c4 u1 CV rm cn ul r, rm rm V) ul 4 c) uD

CM 0000

00 Ch CD • 0

00

Ch

01

00

r,

03 rg 0% 00 rA r4 ON CM CD Ch CM CD Ch Ch CD Ch Ch 00

A a A •• A A 4 4 A

4 •• a IA 4 •• ••• a 4 A

la A •• a •• . 4 4 a •• A

rA r4 C.4 1-4 4.1

44

.

44

CV CV CV rg rg rg rg rg

•• . •• •• •• •• •• •• •• ••

•• 0

Ca

,11

4

t.) V

0H

01,4

.0

1441

0

VW 0,

a:1

•• WI 41

0

0

1-1 0

W CO

r4 rg 04 01 4 U -S ‘0 r, OD Ch

00

0

.1-1

i.4

0

0

404

0

0

r4

i-t

4)

C4)

•

Report No. 1880

NCO ,g eg oh 4

r4 rg Hr4 rg

k

rJJ

CO 4-1

W W.

O.

14 1.4

W W

> P.

0

..c o

Ul

r

g

01 ch CD r4

eA ell- ulm, 1-...

I. HC°4 C.4 NNCA 'NC.] N

UD r--- 00

HHrg

0

00....1

W

ca td

s-.

O c,

> a

1...

.1 0

..t V,

i

4J

a

44 W'

ICI I-1

144

•r1

4-41

41-1

•

0

00

A4

k

m

.

0

W

.q

DO

•

01

-a

0

Li

0

AJ

C.3

CO

to

0

14

0

rd

C4

01

VD

W

,-4

10

ID.

CV

W

r

cd

I:.

..

c, r4

rl 4-1 •I ul CD 00 In

r4 CM CT CA AA r4 el C) ch 01 N. r... 01 CD .-41.4 At ul VD CD r4

rl DO C.4 ul aD c4 CD C) C E

40 CM OD 01 01 VD op N r... r4 04 4 cp 1-- .4 cp 4 01 vi cp

0 c. t

Ch r- 4D r- ch 00 r -. r.... N. op CD Cn •4 cn el CD r- Ch 00 cm Ch r, CA r, r, on ,A

A ...

. .

. .

.

.

I-I r4

r 4

r-I r4

.-4

77

•

••

•

•• • 0 • • • • •• •• • 0 •• •• • •

•• •• •• •• 811 .• •• •• gg ••

CD ,t 4 CD CD 4 4 CD 4

C' 43 40 CD Ch Ul r, r- r....

0' 00 0, 00 CM 03 A, A, r,

CD CD CD CI CD CD 4 CD CP.

44

.

M

.

W

• ••

.

84

W

O

W

.. ..

4J

▪

*

... 4. 0 le

CD CD CD 4 C7 CD CD CD CD

ch on r4 4-4 Lel Cr, r, cr. ul

C7

Cn Cn 0, 47 CO h- on CD4..

A

11 ,4

.4

.. .. .. .. .. ..

"-I

4-1

C

o

u.

W

ca

.

ft

4-1

'q

.0

.. - - - - • • • • - • . - - .. • •

Al

4-4

A

.-1

g

11

CD CD CD CD 4 cp 4 cp 4

Ch 4 Ul CD r4 Ul .7 01 4

0 co ..-♦ (Trio. InONO

.

wr ..

.

•• •• •• •4I M• • • ••

CA As VD VD OD 00 OD AA A,

0

•

04

•

.

r44

M

•• • • •• •• •• ••

CD 4 CD CD CD CD C) C) 4 Cm 1-... co r... 4 N. 01 r4 CD

..

C> CD CD CD C, CD CD CD Ci

ch al 4 4 C) .4 el NO

N. r, r, r- .0 4D on 0' ON

1-4 Ch C4 01 00 4.7 CM C4 VD

00 op •-1 00 C4 00 00 CDo.4-4A

4-4 14

.-.4

. -1

ft

a• •• •• ..•

.1.

4 4

4 C) 4 CD CD CD 4 C) C3

ICON

C4 4 CO MD ...T rn 4,

Ch C, V) r, Ch 03 r..... 03 CO

tn.

CU

0.

.. ..

.. .. .4

LJ

CD -4 CD C) C) 4 4-,C)r...CD

,4

VD 4-4 CD C4 CD C...[ r

C) CD C) CD CD 4 4 4 4

CO 4-4 4 CO 01 r4 Ch ifl C) 4-4 1.4 cp r4 r4 CI C, 03 CN

Awn...

rA rA r4 r4 r4 ,4

.. .. 00

CA 4-I Ch C) CO

.

.

I-I

..

.. -- .. .-

41

q

W

r.

id OM

0

C3', C.1 C)

. ft

w

:4• '-.4d

$4

mD Ch 4-4 O. un r- I-- CD un r-- L.1

h, V) CD Al r, 00 40 00 r, ...*

01 01 01 oD u1 r4 CO un ON

aD CO's

in 03 C) 4D Ch Ul 01 r•••• CM C4

00 r4 00 CD C4 NON al C4 MD

qD

Id

0' r/..0

CD

r,T::

,, cO 0 co ,10

Ch 0chQD

r, c--.

CD 0 0

03 ON CA CA CD r4ACD

co

r, r, CD 03 u1 OD 03

0000

14

.

0

A

A

A

.

a

.

A

W

.4

0

r4

r4 r4 4-4 r4 ,4 ,4

r4 4-4a

r4

P.

<41.1

..

4)

•• •• •• •• • • •• •• •• • • ••

•• •

.•

-- .. -• •- •• •• •• ••

CU

60

44

,4

...I

00

CO

In

4.1

0

g

U3

•

OD

,I

r

q 4

P4

Cd

w

>

..

..

CO..

•

C4

0

P•

.A

•

4-4

W

Ft

CO

0 •

.

rA

r4

1-4

10

CO

.

n

..

4)

.

r4

44

U

cn

0

AA

Sd

..

..

CO

Ow

W

>

.. .. ..

r0

00

DC

W

W

PI,.

W

01

4.1

ca

0

0

r4

•

4

CD

co

M

CI

W

u,

1:14

1 -4

tn

>

..

C4

w

0

r4

r4

•c:b

es

44 . .. .. ... " ..,

1J

93

44

AA

44

1)

.0

43

0

0

..

w

ft

..

•

.. .. ..

Oil. •• •• • • •• •• •• • • • • ••

•4

CD 4 CD CD CD C) CD C) CD CD CD 4 4 CD CD 4 4

un C4 un 03 ,t on 04 4 CD

N. g g., g Q

1"

2 ir:3 g...1

Ch C) cD cl 00 00 Ch CD

. n ft .

41. A

. .

...

P4

4-4

r4 r4 .4 1--I ..-4

e-I A-I

1-1 r-I A4

4

CD CD CD 4 4 CD 4 4 CD

CD A, Cl CO 03 C4 C4 r4 A,

C4 Ch CD r... OD A, OD Ch ,la

co

4.

-

rAl

-

1-4

•• •• ••.

...

.. ..

CD C) cD CD -/ r- 4 CD CD

00

CD 4 .4 C) .4 C) CD cD

VD Cm .--1 r, 01 r4 N4 VD C4 rA CD ,t r4 r, VD

000. Ch C) CT N. N. CD CDa

a. CO CM CO 00 CO 0D.0 OD

.

al /-1

CL.,4

0 .11

4.1

c..1 al

rd XI

aV 1.1

• . • 0 •• • • •4 •• ••

-,

•

co

•

4-4

1,4

04

...

00

r4

p

gl

40i

CU

rd

C.)

tu

g.

0

v-4 $.4p

Report No. 1880

m

CC

,-I

0

P,

'CI

OD co 01 OD C) Cr r4 CD r- CD CD 43 ,4 nci

00 CD Ch VD a) 03 ON al C3 ,t CD r- CD r4 M ul 00

el .4 4 .D 01 C) c4 ,ND VI 00

A, OD .4 e4 r- r..... 04 VD co co

C4 op cm ,r, cp r4 r4 VD .4 ..,1

r4 r4 CD M

CD

---1 C) cn 4-4. CA C4

r- r- Ch ch CD Cr,

04 C).C).C4

C) 00 ON rn OD 03 03 A , A, 00

. . .. .

. . .

.

.

.

W

e4 ,4 ,4 -A

r4

.4 4-4 r4

r4 rA 4-4

rA

r4

/4

0

" " " " " '

.. .. .. .•

.4 ..

.. 4-4 .. .. .. 4.

CD

0

cD

4

CD

CD

C)

CP

CD

7 CD 4 C> CD CD 4 CD 0O CD CD C3 CD CO CD CD CD

44 A

CA ,JD a:, r4 rl Ch OD .4 CM

CD Ul VD r4 4 C, Ch 4 CV

4 rA ul C) ....t ch r4 r4 C)

0 0

00 CO CO A-. Cr, r, C).01.Ch

r4 C4 r4 01 uI r, C) CDA4-4

Ch CO CD r, r, CO CO r, VD

1J

•Cl

A

.

Ana.

CO

4-4

rA

,4

r4

r4

r4

r4r4

r4

r4

34 -i0

P4

..

..

..

•

co

.

..

,..1

..

3 4 0 0 0 0 0 4

7 2 n? Ill' g .:".1 2 -1 CA 03 '4 ch r2 .i .4

CA ch r- r- un 43 .-4. 03 CD

1-4 C4 Ch OD (7 r4 .4 CD C)

.

A

A

A

A •n

. .

1 -1

rI

4-4 r4

r4

,4

..4

r4 r4

.. .. .. .. "

.. .. ..

CD 4 4 4 4 a 4 CD CD

C> CD CD 4 CD C) CD C) CD C) CD C) CD CD ,t CD 4 CD

al •-s. va C4 el aD WI Ch Ch

r4 al 4 al ri 4 C4 C) vl

x1010

CA r- CD C4 C) 00 C4

r4 CD co 03 C., C.3 A4 00 r4

VD ► , OD 03 ul 03 CA 000.

CM CD r4 CD C4 Ch Ch Ch CA

A A A A

.4

r4

r4 r4

r4 1.4 rA 4-4

A4

P4

1-4 r4

4-1 4..4

.--I

CD CD CD C) 4 CD C) CD cD

on vp

r.- r4 01 V) 0.74

N. CO cp 03 VD OD 03 Ch 00

•

.

13.1

..

10

cll

0

r4

0

A

W

.13

Li

IA Ift A fli

ik It

.. .. .. .. .. .. ..

.14.

W

>

;4

Ul

4 CD CD C) CD 4 4 4 CD4 cD CD 4 CD CI C> CD CD

0 v) c0 CD 00 cc) r- v) Cr,

A. 2 5; 'A 070 r, •4 on VD Ch CD u1 04 C)

03 r- NO 03 al al Cn CO Cn

C4 01 c0 OD OD 4 r4 C4 CD

CO CO CD CO VD CA C, OD CM

44

.

•• ••

••

•• ••

•• •• •• ••

r4 04 01 4 un ‘..0 r...

oo ch

..

..

..

..

..

.1

• •

0 bl

n n

0

0 -1-,

CO a]

cd k

94 cu

0 0,

0

4

.4 r4 r4 r4 r r4 .4 r4

V

1-1

0.

0,4 0 4-4 04 rl 4 al m3 I-, 03

.4 .4 .4 r4 ,4 ,4 ..-1 .4 .,

P

0 0

C> C> -4 4 CD C) CD CD ,t

O. VNI

04 q444

433

c" ,"-'.° O. ,

1::.; ',LIL.91 el. ,-r

4. . A

A

co g

A

A .

un 4p r,

. 4C4 CA C4 C4 C4 C4 C4 N

VI Ch CD r4 04 01 4

r••n

C

o) 4-'

tn tt

0 1.4

14 w

o.) 0.

0

,•4

I-I

or

a) a)

w 1-1

14 4

4 4J

.1.3

0)

41)

43

05

44 r4

at

tn ttl

k •4

0 F.74

,"II

4

•

•

•

W

CD P. el CD CT r. ul

cD P. P. rs In CO Ch r4 OD 4, Ul r4

co on t, o, in 01 01 OD r, 01

0 00 CA CO 41 .4 1- ♦ 03 VD 01 0 Ch 0 CO

0 0 WI OD P. r.4 "0 01 Cm cm 0 op cq ,1 VDVD

P.

VD

Ps

MO

41 4) Ps VD OD Ps

rPs

Ps

Ps Ps Ps P. r...

03 r, r, VD VD 43 4, Ps. 1/40 VD

A a a A a a a a ••

fro ..• a a a •• a a P I.

on 6. . a on e. a n a It .0 os

r4 r4 r4 1-4 v-4 r4 r4 1-4 r4

v4 r4 r4 r4 r4 ”4 r4 r4 c-+ v4

1 rr4 r-11-1

,4 r4 r4 ,4 1-4 1-4

(10 ,..1

•

W

to

44

•

1

4•

AI

.4

s4

•

CD CD CD CD 4 4 CD CD CD

e01 Ps r- -4 1-4 CA 1-4 01 C)

oD N op VD VD ,0 Ts N 03

m

a Vs a a a 0 a a a

r4 1-4 1-4 r4 r4 r4 ,4 r4 r4

P4

•

0

O

r4•

C.3

W

U

P.

••

4.4

1/1

00

m

C4

4-1

St4

0

C0

•

,-,

CO

I

•••

.4

II; •

P4

O

• ••

OP

••

•

M

•

VI

•

04

•4

0

PI

D

- -

c n1

to

ta

N

k

Ok

••

I-1

0

0C0•

•

v4

dP

al

4-1

O

•

014

4 ••

•

14

01

.4

1-1

4.i

to

••

04

1:1

0

cd

••

I

•• •• •• •• •• •• ••

•

P: P.' a; 8,

O

O

• • • • • • •• •

r4 r4 r4 1-4 r4 r4 r4 r4 1-4

C3 o CD 4 C) 4 C) CD

! g

Z.17 n421 '43 g"..! zi: P.Aa;••7.-.•n

c?

a V.

a Ph a In a a wa in

•O

a a a a a a

a.

Ul

r,a

u)

•

04

CA 41 Ps r4 41 OD CD r4 Ps

Ns

• t Vs Vs Vs Of Vs V t VS

CD CD CD C) C) 0 4 CD CD

CD VD C4 4 VD VD u1 ul VD

1-i

0

$4

0

Report No. 1880

• '

• • ..

• •

...? 0 0

rs P. VD VD Ps VD 41 VD Ps

r4 r4 r4 r4 r4 1-4♦ r4 r4 r-1 r4 r4 r4 r4 v-4 1-4 r4 r4 r4

a • - a a •• wa a a a a •• a a a a in la

• •

• •

• •

•.-

Q0

4

0

4

• •

4

• •

• '

• •

••

k

4

44

••

Ps

.7 0.4 MI C) OD CA

Ps VD MD r. r- m) r.- 4, op

a a a A in a a a a

a a a a a f.

CD r4 f4 CI

r4

r4 r4

M t:N

0 Cd

4.1

0/

14 11

0) 14

13. •r4

0.0

44

41

Ca) (1)

41 ..W

W 4.1

/4 CI

re-4 mp

%0 r--ult--i-, 1.11,0

01

14

40Q400000

0 0

M44

0 0 0 -..t

sr)

r, 01 01 uI oo 1/40 ,4

,0 %D

• • •• • • •n • FE • • •• •• • • ••

4-1

.0 ' • • • • ' • .'•

0 t .4 CD 0

01 ....7 03 0 II OD VD r4 VD

pn VD Ps rs VD 41 N CO r.

•• SO •• •• •• •• •• •• pp • •

0/ 4 ul m) r- CO cm

•n

1.4 r4 r4 r4 r4 r4 rA r4 r4 • •

r4 rA 1-4 r4 r,4 r4 1-4 vi r4

ti

••

CD CD 0 CD CD CD 40 CD

r4 rA 1-4 r41 r• r4 r4 rA r4

r4 r4 r4 r4 r4 r4 r4 1- ♦ 1- ♦

r•

4)

0

CD C> CD CD CD CD CD .4 C)

03 4 0.4 4 CD 03 Ii 00 P.

VD Ps VD Ps OD 43 VD 41 Ps n W. a a a

. a in

a ...

a a a a a a • ell

(I,

•0

ell

4 4 CD CD 0 4 C) .4 4

.

N r.. cm CD CD 411 ul 4 00

040

44

.011 .0 N .0 VD Ps 4) VD

•

t

Vs

f

s

a

in

V.

f•

. t V.

1:3

r4 r4 r4 r4 v4 r4 r-11-4 r4

••

0 0 0 0 0 0 0 0

1`, VD 01 VD Ps Ms V1 C4

Ps VD 43 MD 41 41 41 ..0

4.1

w0)

a

r4 1-4r4 r4 v4 r4 r4 r4 r4 rA 1.4 r4 1-4 r4 1-4 r4 r4 rA

U

-I

•

a a

N

0)

r4 r4 r4 r4 1-4 v-4 r4 r4 r4

.4

O

r4 r4 CO CO 01 Ps CA N r.c0 I)

01 r.. ,4 en 1-4 CD ”4 41 1-4 CO

-4 ul cm r. op op 4 01 COCA g

P•41 Cn C) r. 4 c4 r4 ml P. •Ps

VD 4) VD 43 41 Ps P. r.mp

40 P. 0 r, r, q) WD ,..0 pn g)

Vs It Is its ft Vs V t 4 t fq 4".

Of ft

a in a n a 0 a

a)

r4 1-4 r4 ,4 r4 ,4 r4 ,4 v4V4 r4 1•4 r4 r4 r4 ,• r4 r4 r4 r4

•• •• • • e• •• •• •• •• •• o•

•••

•

•

••

11. a in a

•

r4 r1 TA r4 r4 v4 1-4 1-4 1-4

CD 4 At C) C3 CD CD CD CD

1-4 V1 4 CA OD '.0 0 CA VD OD '-0 '0 41 VD 41 00 Ul 0

.14

r4

W

ge

4.1

CU

CD CD .4 CD 4 0 CD CD CD

NC) WD VD 4, U1 CA 01 01

43 VD 41 1. m1 r. Ps. r.. VD

g..)

w. a a a Fa In a a a

a In a in a In Vs al a

r4 ,4 1•4 r4♦ r4 r4 r4 r4 r4

•

M

•

04

I 0

E•4,

0

rA r-1 ri r4 1-4 r4 r4 1-4

r4 r4 1.4 r4 rA r4 r4 r4 r4

4 CD C> C> CD 0 4 4 CD

CD

CD

00 t-, V, VD r- 1 43 Ps VD

•

•

M

cd

gD.

4 0 0 0 0 0 0 0

U1 04 CA 01 r4 r4 VD CA 4

v,

r, .1 ul .0. I. v) r-. e--

0

• • •• •• •• •• •• •• •• ••

.r1

•

>

rl

MAD s g

a a a a ••• a n a a a

•

.14

10

it)

•• .- - .. •- .. .- .. .•

8 ,91 2 8 `g 3 IR F. ‘g

.4) CO v) co P. vs ND VD OD

r4 r4 r4 r4 r4 r4 r4 r4 ,.• r4 CU

P

..

CD CD CD C) CD 4 C) CD C)

.0 ,-4 CO CD Ch 01 cr, r) 1-4

co r, 4) N 0 MD VD P. mD

a a •• a a a a In a

r4 r4 r4 rA r4 1-4 r4 r4 r4

co)

CO

(3)

PI

Lai

CD CD At CD CD CD CD CD CD

04

P.

0

0. • • •

Ai

02

0

0

W

O

4

•• an. n a 1% •• • n a a

1 1-1 r4 1-4

• • r4 r4 r-1 s-4 v-

I-4 vi r-1 1-4

..

•

134

I]

...7 r4 r4 00 OD C) Ps CA 01

v) ^pn 0 0 VD Ms Ps 00

Is

• - - - - -

v 1 r 1 9. 1 r 1 r .1

O

C? C) CD C) CD CD .4 CD CD

CD CD

CD 4 p CD CD CD CD C? C)

Ps

CD

V3 Ps VD VD VD r.. Ps MD 1-..

a a It a. Ot a n a a

r4 r4 r4 r4 'A r4 r4 rA r4

• •

• •

• r • . • .

• •

• • • •

- .

CA OD In Oon r, r4 1-4 Ps 01

%.0 rA r4 41

03 rA MN CT M'.0

r, Iss 43 VD VD ul .c) VD VD VD

•

0)

Cd

4

•• e• • • •• • • •• 00 •• •• • •

W

00.1-I

•

W

Cd

sI

CD CD cD CD CD ,t

CD 4 CD CD C) CD CD C) CD

CD CD CD 4 CD CD C) 4 4

N. P. h. T -1 01 1-4

NN a 4

in

ul mi r. r4 Ch 01 r.

P. 00 mp N VD r. CO N 00

r. r, ul r... MD 43 4 VD Ps

in •• •• a

•• 0% •• •• a in a ft V.

r4 r4 r4 r4 1 .4 r.4 r4 r4 r-1

rA r1 r4 r4 r4 1-4 1-4 r4 r4

•

O

•• ••

Il. a a

•• •• •• •• •• a• •• a• •• ••

to

vi

IH0

.ti

• .

*A

....

•

r4

.14

1-1

••

•• •• •• 4,0 •• e• •• • • •• • • ..,1

0

O

O

a

C) r4 r4 Ps Ts v4 f, cD r4 01 r4 v-4 0 Ps. VI op Ul ul coco

CD op cD r4 Ps 0 c) op 00 U1

r-, cm r. U1 C4 VD cl CO r4 C1 r4 v-4 en 4 CA N4 CA 011•

VD r4 01 CO cm P. en mp oP rn

VD VD VD C• ul 1"--, 11-n VD r....0

VD f. .0 r. P. r. r- .0 00 r...

Ps r. vD VD 4) VD VD m) VD ,.0

a Ii. a! II% a a Pi •• a

n •• v. 4. •n tr, a. • 0 •••• ft •• a V. .I, a a a a

r-1 .4 rA r4 r4 r4 1-4 r4 r4 ,-4

r4 r4 r4 1-4 r4 r4 ,-4 r4 r4 r4

r4 r4 r4 ,4 r4 •-4 1.4 v-4 r4 r4

04

›

cQ

•• •

lJ

f t es

1.4

•

00 w4

•

W

U)

44

•

0)

4-P

••

Vs

••

0

wi

r4 r4 1-4 r4 1-4 r4 v4 r4 r4

CD CD CD CD 4 0 C> CD 4

4 C) CD 0 CP 4 CD 4 CD

CA VO VD C4 r- C) CA 01 AT

01 OD on 4 o.... CIO on on ri40 CO

r• Ps 43 P s. 1,03 CO

r„ 43 r- .0 g) ul .0 Ps VD

ael a. 4. •• •• al a a a

I. A •• ••• •• A es w

r4 r4 1-4 r4 r4 r4 r4 1-4 r4

r4 r4 v4 r4 ,4 r4 r4 r4 r4

•

U

to

O

1

-4•

Cd

11.n a In vs I t a •• a W.

l PA PA vl r-4 r-1 vi r-1

•• •n • •• e• •• •• •• •• ••

rn

r4 r4 1.4 r4 r4 1-4 1-4 r4 r4

0 MD 01 CD 4 C4 41 41 C4

coar-.ar,aN. opar.aP.ar.aP.•n

VD VD 41 OD 4 1/40 Ul 41 Ts

op 40 '.0 1-- r- ul VD Ps ,C.

•

cd

.4

4 CD CD 0 CD CD 4 C? st

4 C) .4 Cm r4 CA VD 4 CO

'VD N N in N P. mD co r..

a 141 a a a a n

CD 0 CD CD CD CD CD CD CD

•

U)

r4

nt

MD

CD CD C) CD CD CD 4 4 CD

VD 4 CA N CO VIN CT CD

ps rs. VD op N ul CO N C°

•••

0

;4

• • • • •• •• •• •• •• • • •• ••

• • •

•

01

U

01

uD Ps op

r4 r4 r4 .'4

sa

11 0

est,

H

• cl)

▪

o

CW M .7 v-1

Ch CD PA

ri c4 C4 C4 C4 C4 NN CV

Table 7.--Analysis of variance of strength (300° F.)for specimens

bonded with Adhesive 59

•

Source

a Operators

b

Presses

Press by operators

c

Within operators

F :Significance Testi

:Degrees: Sum of : Mean :

termlevel

of

: squares : square : ratio : .

.

:freedom:

•

.

: Percent

2

'2

4

•.

!

.

.•

•.

•

.•

•

6

Days

d' (test term for days) : 26

d

.

1

79,447 : 13,241 :

: 27,419

:

:

.48 :

Bonding runs

Cleaning runs

Remaining interaction

: 18

: 18

: 30

:

.

•

: 292,274 : 16,237 : 3.37 : : 287,900 : 15,994 : 3.32 : : 403,021 : 13,434 :

Total between panels

! 80

:2,397,049 : 29,963 : 9.32 : Within days within operators : e

f

g

82,276 : 41,138 : 3.11 :

:

:1,224,623 : 612,312 : 27.25 :

6,877 : 1.43 :

:

27,508 :

162

: 520,808 :

3,215 !

g+h Total residual

: 192

; 923,829 :

4,812

Total

; 242

:2,917,857 : 12,057 ;

Total within panels

h

N.S.

1

N.S.

d

ftl'h

g+h

N.S.

d'

1

1

: g+h

: g+h

1

:

h

:

:

••

▪.

:

1

-Symbols

refer to corresponding symbols in first column under source.

Grand average--918 pounds per square inch.

Overall standard deviation--109.8 pounds per square inch.

Coefficient of variation--12.0 percent.

Table 8. --Analy sis of variance of stren gth (500° F.) for specimens

bonded with Adhesive 61

Source

Operators

a

Presses

b

c Press by operators

•

•

•

:

:Significance: Test

F

:

:Degrees: Sum of : Mean

: terml

level

: squares : square : ratio :

of

:freedom:

. . .

:

.

: Percent

:

:

:

2

2

4

Within operators

: 123,052 : 61,526 : 2.04 : : 170,185 : 85,092 : 8.69 : : 157,741 : 39,435 : 4.03 : •.

:

.

••

••

:

Days

d'

(test

Bonding runs

Cleaning runs

Remaining interaction

: 18

: 18

: 30

Total between panels

! 80

: 256,318 : 14,240 : 1.45 :

: 527,563 : 29,309 : 2.99 :

: 663,156 : 22,105

.

:2,078,733 : 25,984 : 3.46 : Total within panels

: 162

:1,215,867 :

g+h Total residual

: 192

:1,879,023 :9,787

Total

; 242

:3,294,600 : 13,614

e

f

g

h

:

:

N.S.

1

1

: g+h

: g+h

:

:

7,505

.

1

-Symbols

refer to corresponding symbols in first column under source.

Grand average--1,962 pounds per square inch.

Overall standard deviation--116.7 pounds per square inch.

Coefficient of variation--5.9 percent.

Report No. 1880

: d'

N.S.

19..

:

•

d

: g+h

g+h

:

.89 :

: 180,718; 30,120 :

:

6

33,762

term for : days)

:

:

••

•

•.

••

Within days within operators :

d

N.S.

1

1

:

h

•

Table 9.--Analysis of variance of strength at 500° F. for specimens

bonded with Adhesive 63

Source

•

.

•

•

•

F

:Significance: Test

:

:Degrees: Sum of : Mean

level

: term: squares : square : ratio :

of

:freedom:

: Percent

a

b

c

Operators

Presses

Presses by operators

:

!

2

2

4

:

:

6

14

:1,463,016 : 731,508 :

: 183,695 : 91,848 :

: 639,752 : 159,938 :

5.21 :

4.64 :

8.08 :

5

5

1

:

:

:

g+h

g+h

d

842,254 : 140,376 :

: 47,660

2.95 !

5

:

d'

Within operators

d

Days

d' (test term for days)

:

:

•

Within days within operators :

..:

e

Bonding runs

:

f

Cleaning runs

:

g

Remaining interaction

:

18

18

30

:

:

: 934,332 :

: 280,022 :

:1,052,257 :

51,907 :

15,557 :

35,075 :

2.62 :

.79 :

1

N.S.

:

:

g+h

g+h

3.97 !

1

:

h

Total between panels

:

80

:5,395,328 :

67,442 :

Total within panels

: 162

:2,750,155 :

16,976

g+h Total residual

: 192

:3,802,412 :

19,804

Total

: 242

:8,145,483 :

33,659 :

h

1

-Symbo/s refer to corresponding symbols in first column under source.

Grand average---931 pounds per square inch.

Overall standard deviation--183.5 pounds per square inch.

Coefficient of variation-19.7 percent.

Table 10.--Analysis of variance of strength at 500° F. for specimens

bonded with Adhesive 64

•. Source

.•

•

:Significance: Testi

F

Mean :

:Degrees: Sum of :

: termlevel

: squares : square : ratio :

of

.

:freedom:

: Percent

.

a

b

c

2

2

4

Operators

Presses

Press by operators

:

:

:

06,454 : 43,227 : 1.08 : 67,604 : 33,802 : 8.73 :

59,093 : 14,773 : 3.82 : N.S.

1

1

d

g+h

g+h

Within operators

•

d

Days

d' (test term for days) 6

23

: 240,407 : 40,068 : 2.45 :

: 16,344 :

:

N.S.

: d'

Within days within operators :

•

•

Bonding runs

Cleaning runs

Remaining interaction

: 18

: 18

: 30

8,480 : 2.19 :

: 152,644 :

: 211,215 : 11,734 : 3.03 :

5,861 :

: 175,828 :

1

1

Total between panels

! 80

! 993,245 ! 12,416 : 3.55 :

1

Total within panels

: 162

! 567,173 :

3,501 !

g+h Total residual

: 192

: 743,001 :

3,870

Total

; 242

:1,560,418 :

6,448

e

f

g

h

1

-Symbols refer to corresponding symbols in first column under source.

Grand average--1,696 pounds per square inch.

Overall standard deviation--80.3 pounds per square inch.

Coefficient of variation--4.7 percent.

Report No. 1880

g+h

: g+h

•

Figure 2. -- Technique of cutting lap-joint panels with multiple saws.

(ZM 110 203)

a

Figure 3. --Universal-type test machine, oven and controller, and potentiometer

used in tensile shear tests at elevated temperatures.

(ZM 79837 F)

•