THE SAP OR MOISTURE IN WOO D q Revised January 1959

THE SAP OR MOISTURE

IN WOO D

Revised January 1959

FOREST PRODUCTS LIBRAR Y

FOREST RESEARCH LABORATOR Y

OREGON STATE UNIVERSITY

No. 768 p ►q-c

FOREST PRODUCTS LABORATOR Y

MADISON 5 , WISCONSIN'

UNITED STATES DEPARTMENT OF AGRICULTUR E

FOREST SERVIC E

In Cooperation with the University of Wisconsi n

THE SAP OR MOISTURE IN WOOD-,

By

E . C . PECK, Technologist , . -

Forest Products -Laborator y,-Forest Service

U . S . Department of Agricultur e

S

Meaning of "Sap "

By ".sap" is meant the moisture in wood and all material it holds in ,solution .

The amount and kind of materials dissolved in the water of the sap vary wit h the species, part of tree, and time of year, but constitute only a small amoun t cif the sap .

In drying lumber it is principally the moisture that evaporates, leavingth e soluble materials behind, although some acid and volatile oils also pass of f in the form of vapor . In pine, Douglas-fir, and some 1cedars the volatile oils .

constitute an appreciable part of the evaporated materials .

_

The'

$• olublst materials in the sapwood are mostly sugar, and a very

'mount of trrineral matter, while 'in the heartwood they are tannins, resin , dyestuffs, and other materials . To what extent these materials affect th e utilization of wood is not definitely known, and, if they' do practical means of removing them .

.

small affect it there in water for a year or more dry more easily and shrink less, but-definit e proof is lacking .

is no

3 It has been said-that logs that have' bee n

Kiln drying and steaming do not remove the starches, sugars, albuminou s material, and the like to any appreciable-extent, , as it has been sorinetimne s claimed . If they are removed, the wood would not become , stronger, nor mor e decay resistant . _ Heartwood might be less decay resistant because such materials as the tannins help it to resist decay . Sapwood is not natural cly decay resistant, and the removal of materials would not 'improve its resistance .

!Report originally published August 1953 .

ZMaintained at Madison, Wis . , in cooperation'with the=.Unvrsitj~ of'1?isEO,nsi .

_Ponderosa pine has been seasoned by treatment with .a solvent does remove resin, and other materials, but the . grocess . .is appa -ently limited in its application .

liquid ', w i a

Rept . No . D'76~

In kiln drying, operators speak of the moisture content of the wood an d ignore the soluble materials in the sap .

How the Amount of Moisture in Wood is Expresse d

It is customary to express the amount of moisture in wood in terms o f percent of the weight of the dry wood substance . For example, if a piec e of wood weighing 120 grams contained 100 grams of wood and 20 grams o f water, its moisture content expressed in the usual terms would be 2 0 percent . This term is relative and does not give a measure of the absolut e amount of moisture unless the density of the wood is taken into consideration. A piece of oak at 20 percent moisture content contains more moistur e than a piece of pine of the same dimension at the same moisture content .

Fiber-Saturation Point

The moisture in green or wet wood is held in two ways : (1) within the cel l cavities, and (2) within the cell walls . When wood dries, the cell cavitie s become empty before the cell walls begin to give off moisture . When dr y wood takes up moisture, the cell walls become saturated before the cel l cavities fill up . The condition in which the cells are empty but the cel l walls are saturated, is known as the "fiber saturation point. " It is generally considered to be about 30 percent moisture content .

In drying wood, _parts of it may be below the fiber saturation point and shrink , or attempt to shrink, while other parts may be above the fiber saturatio n point and do not shrink . As a consequence, severe stresses are set u p within the wood .

Variation in Moisture Conten t

In Green Wood

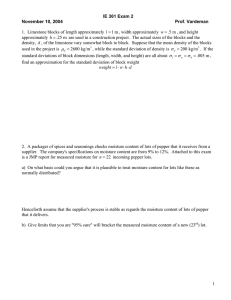

The moisture content of green wood varies from about 30 to about 250 per cent, as shown in table 1 . Figure 1 at the end of this report, shows th e maximum possible moisture content values based-on the specific gravity o f the wood.

Sapwood usually contains more moisture than heartwood, but the heartwoo d of some hardwoods and of cypress is also very wet .

Rept .~ .' No . D768 -2 -

Butt logs usually contain more water than top logs .

There is practically in different seasons no difference in the moisture content of wood cu t of the year, as shown in table 2 .

In Air-Dry Woo d

The variation in moisture content in air-dry wood is due to difference s in climatic conditions (table 3), length of time in the pile, position i n the pile, and kind of stock .

The following tabulation of moisture content of small blocks of woo d thoroughly air dried at New Haven, Conn ., indicates that wood reache s about the same moisture content regardless of species .

Species Moisture

Percent

Ash, black

Ash, white

Chestnut

Douglas-fir

Maple, hard

Pine, loblolly

Pine, longleaf

Pine, white

Spruce, red

Sweetgum

Average . .

14. 9

14. 4

13 . 8

14. 1

14 . 9

14 . 7

13 . 3

13 . 4

15 . 0

140 9

14. 3

Some southern yellow pine 8by

16-inch timbers were found to contain 2 2 percent moisture in the core and 17 percent in layers from the surface t o one-half of the distance to the center after 21 months of air drying unde r cover . Redwood timbers 8 by 16 inches contained 17 percent moisture i n the outer layers and 33 percent in the core after 20 months of air drying .

In Kiln-Dried Wood

Variations in the moisture content of kiln-dried wood are caused b y mechanical inefficiency of the kiln, insufficient length of time in the kiln , and inherent differences in the drying characteristics of individual pieces .

Repte No . D768

Some years ago the Laboratory collected considerable data on the moisture content of kiln-dried softwood lumber at the time of shipmen t from the .s.awmills . .The following tabulation give.R

she of these data on the average moisture content and ranges for all the principal'

sates

woods .

Uppers . . .:;:r

Common

Moisture conten t

Average

. Range of 80 per cent of the stoc k

Percent Percent

16

.5 - 16

1

8,- 2 2

Hardwoods are usually first air dried and then kiln dried at-the point of . .

consumption. When a charge of hardwood lumber is put into a dry kiln, • • the moisture content is lower and the difference between individual boaxd .s

is less . For these reasons, and becaus .e the drying usually longe r , time in the kiln is "

,- the range in moisture content among the hardwood board s at the time of discharge is generally less than in softwoods .

In Storag e

Lumber in storage usually becomes more uniform in moisture content ;' that is, the boards of higher moisture content los e' moisture while thos e of lower moisture content take on moisture . Whether the average mdis.ture content becomes lower or higher depends upoti the average moistur e content when placed in storage and the conditions in the shed . f Lumber in storage is usually solid piled so that only a small area comes in contac t with the atmosphere of the shed . Consequently, where dry lumber is store d under relatively moist conditions, both the average and the variations i n moisture content among the individual boards are increased .

A monorail package of-Douglas-fir lumber that was in a storage shed fo r

'2 .

11, 2 years, illustrates the change in moisture content during storage . The initial . average moisture content was 6 percent and the final average was 1 1 percent, brought about by a gradual' pickup of moisture during the period o f storage .

Rept. No, D768 -4 -

In Service

Wood in actual service will be found to possess variations in moistur e content brought about by the changing . conditions to which it is exposed .

A study of the moisture content of woodwork within dwelling house s indicates what these variations are for this class of material . The chie f determining factors are climate, season ., and position in the dwelling .

Tables 4 and 5 illustrate the variations in moisture content due to som e of these causes .

Rept. No . D768 ' -5- .

Table 1 . --Average moisture content of green wood

Species Moisture content].

------------------------------------ -

Heartwood Sapwood! Mixed heartwoo d and sapwood '

Percent Percent Percent .

SOFTWOODS

Baldcypress

Cedar :

Alaska-

Eastern redc_edar

Incense- .

Northern white-,

Port-Orford-

Atlantic white-

Western redcedar .. .

.

i

121

32

3 3

40

50

58

171

166

21 3 t

98 . .

1

249

: :n• . .;

5 5

. ..,

3 5

. . .

Douglas-fir :

Coast type

Intermediate type

Rocky Mountain type

Fir :

Alpine

Balsam.. .

.

California red . .

Grand

_Noble,

Pacific silver . . .

,White

Hemlock :

-Eastern

'Western

37

34

30

9 1

3 4

5 5

98

97

85

115

154

112

13 6

115

0

16 4

160

11 9

17 0

0 . .

.

A ..

47

:. .1,k:l: : .

..

u~

;: : ; :.;} . ::

11 7

10 8

----------- -

Larch, western

Pine :

Eastern white

Lodgepole .

. . .

Ponderosa

54

41

40

119 • :

120 .

14 8 n

6 8

. .

Rept . No . D768 (Sheet 1 of -5)

Table 1 . --Average moisture content of green wood (continued)

Species Moisture contend

: Heartwood : Sapwood : Mixed heartwoo d and sapwood

Percent : Percent : Percent

SOFTWOODS (continued)

Pine (continued) :

Red

Southern yellow :

Loblolly

Longleaf

Shortleaf

Sugar

Western white

Redwood:

Second -growth

Old-growth

Spruce :

Eastern

Engelmann

Sitka :

:

3 2

33

31

32

98

62

86

34

51

41

.

134

11 0

10 6

12 2

21 9

148

210

128

173

142

127

Tamarack

HARDWOOD S

Alder, red

Apple .'

Ash :

Black

Green

White

Aspen (quaking and bigtooth)

Basswood

Beech

:

:

49

81

95

46

95

81

55

.

.

.

: 97

74

58

44

113

133

72 . .. .

Rept . No . D768 (Sheet 2 of 5)

Table 1 . --Average moisture content of green wood (continued )

Species r .

•

:

---------------------------------------

Heartwood : Sapwood : Mixed heartwoo d

and sapwood

:

Percent : Percent :

:

Percen t

--w?v F

HARDWOODS (continued )

Birch:

Paper

Sweet

Yellow

Buckeye, yellow

Butternut

California-laurel

Cherry, black.'

Chestnut

Chinquapin

Cottonwood, black

Dogwood, flower-ing

Elm :

American

Cedar

Rock '

Hackberry

Hickory :

Bitternut

Mo.cke rnut

Pignut

Red

Sand

Water

:

:

: : :

:

:

:

:

:

89

75

74

58

120

162

80

7 0

7 1

69

6 8

9 7

9 5 .

6 6

4 4

6 1

Y

72

70

72

146

92

61 •

66 -f

5 4

52

52

50

62, •

•

•

:4

:

14 1

104

65

134

6 2

. . . .

:_

;i;• Ti q

~ : -

-

.-

,Rept. No . D768

(Sheet -3 of 5_ )

57.

. --Average moisture content of green wood (continued)

Moisture content!

Heartwood :

Sapwood a

Mixed heartwoo d and sapwood

Percent : Percent a Percent

: . 8 2

Maple :

Silver (soft)

Sugar (hard) s

Oak:

California black .

Live orxlrnared oii+rr}_ x ed

._.

Soub ern. swamp

~,

White

:

: 76

8 0

83

79

64

97 . . . . . . . . . . . . . . . . .

72 . . . . . . . . . . . . . . . . . .

75 ,

6

9 75 . . . . . . . . . . . . . . . . . .

66 . . . . . . . . . . . . . . . . . .

78

89

. . . . . . . . . . . . . . . . .

8 7 ,

10 1

150

13 0

115

108

11 6

(Sheet 4 of 5 )

Table ].--Average moisture content , of green wood (continued)

Species

HARDWOODS ' (continued Y

Walnut, , black

Willow, black i

Yellow-poplar

.Based on weight when oven -

:

:

;

Moisture conten d

Heartwood :. Sapwood :

.

Mixed heartwood sapwoo d and

Percent Pe]cent^ : - - • • Percent '' "

90

83'

73

:

: 106

' :139

: .. . :

Dept . No . D768 (Sheet 5 of 5)

Table 2 .--Percent of moisture in green wood cut during different season s

Doug- : Average : Average :

Month : Arbor- : las- : of.24 . .. : , of 5 : Chest- :

: vitae : fir : European : European : nut

:_m

:hardwoods : conifers :

Loblolly pine e m

,Sapwood : Heartwood

Jan .

Feb .

,

40

,

47

: 47 : 48

, e

60)

58 ) :

91

-

Winter 109

®

Mar .

: --

Apr .

: 82 :

49

38 :

44 -

43 .

:

59 )

54 ) : 89 : Spring 107

May : 74 40 : 43 60 )

------ -

.84

July : 84

'Aug, : 77

.

.

33 41

28 : 45

• 39

61 )

60 ) : 89 : Summer 107

)

• .

59 m_,m---mom-a~®ee e

48

57

Sept .

:

71

Oct .

Nov .

87

80

---~

34

42

T

43

40

58 ) :

58 )

) 88 Autumn 100 47

Dec .

90 39

Table 3 .--Approximate moisture content of thoroughly air-dry stock bymonth s for different regions_

Forest regio n

Jan . : Feb . : Mar . : Apr . : May :June :July :Aug . :Sept . :Oct . :Nov . :Dec .

California pine

Redwood

Inland

Empire?

: 20 :

24 :

18 .

25 :

16 :

22

14

20

▪

12 : 10 :

18 : 16 :

9 : 9

15 : 15

10 : 12

16 : 17

16 : 18

19 21

: 20 : 20 : 18 : 15 : 14 : 14 :12 .5 : 13 : 14 : 15 20 20

Oregon an d

Washington 15 : 16 22 . 26

Southern pine 20 : 13 : .

14 14 14 r 16 17 20 l In the arid Southwest during the driest portion of the year air-dry lumbe r dries down to between 5 and 10 percent moisture content .

.

?

.Northwestern Montana, Idaho north of the Salmon River, Washington east of the

Cascade Mountains, and the northeastern tip of Oregon .

Rept . No . D76 8

26 : 24 • 22 : 18 16 :

• 15 :

12 : 13

Table 4 .--Variations in percentage of moisture content of wood i n dwelling houses due to geographic location and seaso n

City

Moisture conten t

: High : Low : Range

New Orleans, La .

San Francisco, Calif .

Portland, Oreg .

Washington, D . C .

Madison, Wis .

Alburquerque, N . M .

13 .4

.

11 .6

.

10 .9

.

9 .6

.

11 .9

.

.

10 .2

.

9 .2

8 .2

.

1 .8

1 . 7

1 . 4

8 .2

.

3 .7

6 .4

3 . 8

8 .6

.

5 .4

.

3 .2

Table 5 .--Variations in percentage of moisture content of wood i n dwelling houses due to position in the house l

Location

Moisture content

: Summer : Winter : Range

Cellar (over heating plant)

Cellar (other parts)

Living room, kitchen, bedroom , and bathroom

Hall

Attic

=Houses in Madison, Wis .

.

13 .1

:

.

13 .8

:

: 10 .2

.

.

11 .0

.

7 .3

.

5 .1

.

8 .0 -

8 .o

.

5 . 8

6 .4

.

3 . 8

7 .5

3 .5

9 .2

: 1 . 9

Rept . No .

D768

400

350

300

250

200

/00

50

0

0 0.5

/.0

SPEC/F/C GRAVIT Y

(GREEN VOLUME, OVEN-DRY WEIGHT)

/.5

Figure 1 . --Moisture content limits of wood of variou s specific gravities .

Z M 90364

SUBJECT LISTS OF PUBLICATIONS ISSUED BY I n

FOREST PRODUCTS LABORATORY

The following are obtainable free on request from the Director, Forest Product s

Laboratory, Madison

5,

Wisconsin :

List of publications o n

Box and Crate'Construction and Packaging Dat a

List of publications on

Fire Protection

List of publications o n

Chemistry of Wood and

Derived . Products

List of publications on

Logging, Milling, and

Utilization of Timber

Products

List of publications on

Pulp and Paper

List of publications on

Fungus Defects in Forest

Products and Decay in Tree s

List of publications on -

Glue, Glued Product s and Veneer

List of publications on

Growth) Structure, and

Identification of Wood .

List of publications on

Seasoning of Woo d

List of publications on

Structural Sandwich, Plasti c

Laminates, and Wood-Bas e

Aircraft Component s

List of publications on

Wood Finishing List of publications on

Mechanical Properties an d

Structural Uses of Wood and Wood Product s

List of publications on

Wood Preservation

Partial list of publication s for Architects, Builders ,

Engineers, and Retail

Lumbermen

Partial list of publication s for Furniture Manufacturers ,

Woodworkers

Woodshop and Teachers of

Practice

Note : Since Forest Products Laboratory publications are so varied in subjec t no single list is issued . Instead a list is made up for each Laborator y division. Twice . a year, December 31 and June 30, a list is made u p showing new reports for the previous six months . This is the only ite m sent regularly to the Laboratory's mailing list . Anyone who has aske d for and received the proper subject lists and who has had his name place d on the mailing list can keep up to date on Forest Products Laborator y publications . Each subject list carries descriptions of all other sub ject lists .