FOREST PRODUCTS LABORATORY

advertisement

U. S. Department of Agriculture, Forest Service

FOREST PRODUCTS LABORATOR Y

In cooperation with the University of Wisconsin

TESTS TO DETERMINE THE TIME REQUIRED FO R

SILICATE OF SODA TO REACH ITS MAXIMU M

HOLDING POWER WHEN USED ON FIBREBOAR D

o-

By H . M . HAL E

Industrial Expert in Forest Products

.

'

-.; '

TESTS TO DETERMINE THE TIME REQUIRED FOR SILICATE OF SODA TO REAC H

ITS

?I,M%l SMOG POWER WHEN USED 0 t$RE BOARD

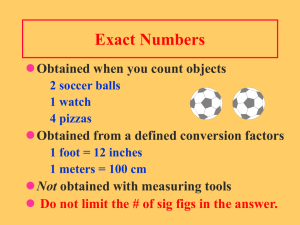

Introduction

. Following a series of e cperimeni_s ,on 150 fibre board boxe s

containing L one-pound condensed milk cams,• in which it was observe d

that 14 percent of the failures were trasea b ,l.'- e to failure at the fla p

joint when the box was sealed, the experients ineluded in this repor t

were made .

The details of the previous experiments are to be found in th e

First Progress Report, "Tests on Fibre Board Shipping Containers for th e

Improvement of Design and Specifications," by A . H . Mackenzie, approve d

December 30, 191 g .

The high percentage of sealing joint failures with the us e

el silicate of soda indicated the need for the de :ve,lopment of a sealing

method which would redure the percentage of joint failures before othe r

methods of improving the design could be takpm up .

The earlier teats suggested five possible so zrces of weaknes s

at the joint :

1 . The length of time required for the si irc 'e at' soda to set, and

the wet paper to regain its strength .

2. The composition and specific gravity of the silicate off` soda.

3. The temperature conditions under which the seal

4. Lack of sufficient pressure to insure coit .ac*

..

5. The temperature Q.f the box after aaaling .

8376

is done .,

+

1 ti

i •%-r

. - 1 '_ The first condition appears to be the controlling one ; the

*econd and third are negligible under ordinary conditions ; the fourth i s

important to the degree of insuring contact only ; the fifth has some effect ,

but just how much is difficult to determine .

i

~;•

1

SiOlI

ishould be noted that in the second condition but tw o

1of silicate of soda were observed and the chemical analysi s

teem to be very similar . The samples represented each c1 .ss .

Pressure sufficient to insure contact is necessary . qge t

unit**

ults . In tests on fibre boxes it was found that the sealin g

was

pendable when the covers were weighted with approximately 5 0

en with this weight carefully applied it is unusual to obtai n

t'C'0s1t tf joint contact between the flaps . The warp in the tw o

beards coax osing the flaps is sufficient to hold them apart for at leas t

i ,• .

- A

d doubtle s has an

The

ratura

'

a bl+1

ill ~!! 44re

S

.0~e . This is a deductio n

sis of the very short time required fo r

Bch can safely be made on t'

t* silicate tg_ ;.et Q, the emples at a temperature . of 120° F .

' Methods

ter '

• "

:--

'$ections of fibre 1o`aA'.' approximateTel inch by - 1/2 inche s

1/2 inches and joined with silicate of soda . The sample s

owed to dry for periods varying from 5 minutes to 20 hours .

2Dg,-Lilaw intervals of drying from 5 minutes to 20 hours were observed .

040 ■ak Or samples was dried under pressure of 2/3 pounds per square inc h

aAOWNPt . The other series was dried without continuous pressure . The

0 066

which were .O SO inch board rated at 200-pound Mullen test ,

the Reihle cement testing machine . The board unde r

* brea at 290 pounds per 1 inch cross section . Similar sample s

-OW hilted aft silicate applied to (1) one board, (2) to both boards .

uelzr

were

Resullwhich are shown in ,elMjg'~'-- in the attached tabulatio n

than

11% That

,

e applied ' a- lob

duces no stronger join

VS 'loth s •aces

frequeatly

re4lts

in a weaker one .

•

2 . Th4 1 ilicate of soda addiFieflWiNlithat no failures occur i n

t Sint

to the silicate

ly aft* 10 minutes and very seldom

at 5 minutes . The joint does not appear to get its maximum strength fo r

about 4 hours, probably due to a softening action in the kraft itself o r

in kraft chip glue .

3 . The application of pressure to the glued joints usually result s

in a slightly higher average breaking strength than when no pressure i s

applied . A careful analysis of the original sheets, however, shows tha t

the individual samples break at a much more uniform load when they hav e

been dried under pressure than otherwise ; in other words, the extremes ar e

narrower .

The conclusion is that the maximum strength is not reache d

until 4 hours have been given the silicate of soda for setting. Th e

intermediate findings between 5 minutes and 4 hours do not follow a

regular curve, either for the samples under pressure or no pressure . At

5 minutes the breaking strength is 55 pounds with one sample of silicat e

of soda and 54 with the other . This indicates no difference in th e

strength of the two samples of silicate of soda . At 4 hours one sampl e

shows a breaking strength of 109 pounds and the other 106 . Th e

inconsistent part of the results is found in the intermediate periods .

For example, the tests with one sample show the breaking strength a t

30 minutes to be greater than at 40 minutes, 60 minutes, 1-1/2 hours o r

2 hours . At 4 hours the strength equals that at 30 minutes . Probably a

softening action has taken place in the kraft itself or the kraft-chi p

glue, which is not overcome until 4 hours or more have elapsed . One

point is clear, namely that maximum strength at the joint is seldo m

reached in less than 4 hours . After 30 minutes or more setting th e

silicate joint shows an average strength of between 80 percent and 9 0

percent of the maximum strength .

It has been determined that the application of the silicate o f

soda to the fibre board softens the kraft liner, which is the larg e

factor in the tensile strength of the board . This absorption of th e

water from the silicate of soda weakens the joint by this softening

action .

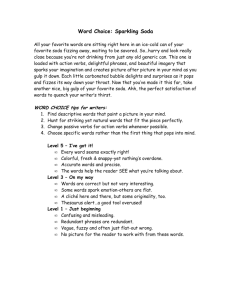

A possible explanation of the erratic results as indicated o n

the accompanying chart may be found in the fact that the silicate of sod a

was applied with a brush which makes the absolute control of the quantit y

applied impossible .

The absorption of moisture tends to weaken the silicate join t

between the kraft and the chip . Before the board can reach its maximu m

strength, this water must have been evaporated through it, which becaus e

of its thickness is a slow process . This accounts for the fact tha t

several hours are necessary for the joint to reach its maximum strength .

All failures occur in the joint by the kraft splitting or pulling fro m

the chips .

x376

-3-

-1

'tf soda, one obtained in th e

,41 ,c

e► it market 06oc.al drug OiWeo, the second from a large manufacturer o f

bested in 4etopacison to determine their relative strengt h

fibre boxeCy'w.

ode as the result of laborator y

in a join$ This iii a experir mte w

ai j oint failure s

record?s s-h 1

anti exe

Tonally Mgt' pe!x=

a

.' ' ,4laO

in a .series, 'bf drum tests on fd

texas . .

..

kv . The 140 00 two batc :Mk'

st revealed

An analysis of these samples by the :laborat p

loo d-- silicat e

no marked difference in their composition . The two s•

of soda were carried through a series of identical t€ ts, aid alined i n

lusivelo That the

cif this report . Results show c

the first pap ii silicate of soda purchased in the open market ways .izliy as ERo% if no t

better, than the article furnished by the box mere, %el teaure g' noted i n

earlier drum tests can safely be ascribed to in st fi€ -exit tip* having bee n

wstse/m4o eW 6e4m to set . No record was n !e of Wt *time allowe d

Strum

_

for Petting in the earlier experiments .

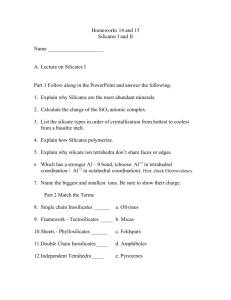

Vib sQialysis of the silicate of soda sainp&e

OW4 is as follows :

. Per- :Percent :Silicate :

Sample

:Specific : Per- : cent : silica : n- umber :Original : Organi c

number and :gravity : cent : total : T .S . - :% silica :

: matte r

description :

: Na 20 :solids : Na20

: %Na20 .

No . 1 from

:

C . M .& L . Co . : 1 .3918 : 8 .1+5 : 37 .17 : 28 .72 : 3 .40

No . 2 from

dru- stare

:

:

. 1 .3979 : 8 .72 : 141 .27 : 32 .55 : 3 .73

:Colorless

. Non e

.

:Caramel : Consider abl e

.

Effect of Temperature on Rate of Drying ,

e.Testmado rinethfcoempratunh

strength of the silicate joint at varying periods of time after joining s

were made on sample strips of fibre board . The results show that fo r

normal working temperature, that is, between 450 F . and 760 F ., the

influence is so slight that this factor could not be detected .

That temperature has a marked effect on the rate of drying unde r

extreme conditions was demonstrated .

8376

-LE-

'j

1

It

-,

.

r_

J

1I -

-I r

At 120° F. the joint reached W percent of its maxis= strength

in 2 minutes . The average maximum strength -circler these temperatur e

conditions was reached in 5 minutes . Humidity was not determined, but as

the work was done in an ordinary electric drying oven the humidity w

not be excessive . At 32° F . more than 3 hours were required to reac h

approximately the same result .

fi

'for

L1

1 _ _1• .

Ill

• D.

-C4

►•

ug-• •

t.

~1

1

n

"9

w

r =,

:~,~

II

-

.

~r'

I

" I il 47_ 1 1111H•

8376

-{

r.

IA1' P

►

` nl

+

_r-.

II

L

-4

r

'

C7

L7

E-i

TESTS ON SODIUM SILICAT E

Box Mfgr . Sample 2 Nat S103

Working Temperature 68° F .

0

CD

[7

~, ~;

a w

Time

1

5 min .

10

II

20

II

30

,I

40

,I

6o

Ir

90

n

120

tl

!l1~1

Ar,f

~, . .

r5

11

72

8

43

10

64

6

53

9

8

10 9

°

1O

83

6o

10

82

10

5s

10

85

10

56

_19

5a

9

91

.-.. J

20

C

10 8

2

17

81

16

90

I

4

• ,.

/

,/f7 z

i

r

-_

■ffil,7 .wry '""'' /7 a/

Air

.rr

AFTAWIlWAPIrdGMA

-?

s~~xsi

Ga '

.~i1"1.~r

.t_ _

wjr nr.~nr~r~rar

r_ __,,,,j

I

lI

E

. .,

1f

/~

,rs

Pressurai

No pressur e

Pressure 2/3 lbs . per sq. in,

i

I

r

54

8

~.~rtasa

240 I I i7I

.1.i~.1T~r'rr/

20 hr .

10

I

O

1G V

40

y._

0

f

Time

i1

20

u

CI_T

777-77;i

't

4o

It

60

t,

..r

rr

1

--

garrAs.

►~

~..r ,rr~r .r

■.

22

„r

!~

90

sArrrrr~~r

}i

120 s

t

240 n

_

7

7':Z

.l.mW

rr

40 R

.g

ym

,■

-:

r®r

J

~►~ '

g5

61

10

g

11

59

9

10

93

39

10

89

5

7s

10

86

10

67

0

10

73

52

10

72

75

"T .77 71

AP71r

10 5

S

D

2

L

.

-

t

Pressure 1

I No pre s sure; 7

Pressure 2/3 lbs . per sq. in.

55

56

10

- ].0

-

t:,

24

Ar

j :;-~ ;7-

°

a) 4

,

PI Elf)

c)

9

13

_

_,

r

r+ 4

o

-

e► r~r r~■Orr

30

a

N

m

T

5 =in.

10

+,

TESTS ON SODIUM SILICATE

Drug Store Purchase Sample 2 N A2 51 03

Working Temperature 68° F .

2

].1

12 0

83