Document 10973914

advertisement

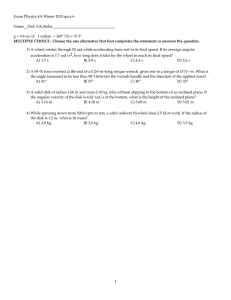

2006-07 Annual Senior Design Seminar Wednesday, May 2, 2007 ITC 7 3:00 – 5:00 pm Department of Industrial Technology, College of Natural Sciences. DC ELECTRIC TORQUE WRENCH PROJECT IN JOHN DEERE WATERLOO WORKS Presenter: Loren Leusink Faculty Advisor: Dr. R. Pecen Sponsor/Industry Supervisor: Brenda Dudley, Donald Swanson, John Deere Waterloo Works. Time: 3:00-3:20 pm Objectives include; (1) install one Cleco electric torque wrench for tightening cab mount bolts, (2) implement the torque wrench with the line automation, (3) mistake proof the cab drop zone to prevent any cab from dropping on the wrench, (4) collect torque data on each tractor for quality purposes. The flat-top conveyor is stopped if either one or both of the Cleco torque wrenches do not torque a joint to specifications. Some possible fault conditions are: high torque, low torque, high angle, low angle, or the tool was not used on the joint. The rundown data is stored in a database and tied to the tractor serial number for Quality Engineers to work with. UPS-Uninterruptible Power Supply Design Presenters: Jared Seltrecht & Dane Oelmann Faculty Advisor: Dr. R. Pecen Time: 3:20-3:40 pm This project includes design and implementation of a 500 W UPS circuit that includes a custom-design charger, a voltage controller, a comparator, a power amplifier, an inverter and a rectifier circuits. A UPS is basically a backup battery for loads like computer, TV, or any load that end users don’t want to experience a power interruption. Project combines testing and implementing power converting methods along with digital and analog monitoring and recording equipment. UPS provides electricity to certain number of loads when a power interruption occurs. ECO-FRIENDLY ZERO-EMISSION LAWN MOWER “” Presenters: John Gregorich Faculty Advisor: Dr. R. Pecen. Sponsor/Industry Supervisor: CNS SOAR Grant, Iowa Energy Center, Lawrence Gregorich, Sr., Ryder Transportation Services. Time: 3:40-4:00 pm With the growing concern of air pollution, environmental impacts and growing demand on fossil fuels, an ecofriendly lawn mower is developed at UNI. Operating a gas mower for 1 hr produces the same pollution as driving a car 1300 miles. Each weekend, about 54 Million Americans mow their lawns, using 800 M gallons of gas per year. An EPA study found that approximately 9 % of some types of air pollutants nationwide come from lawn & garden equipment small engines. This project included converting a conventional lawn mower to a solar powered unique machine called “UNIMow” by installing a PMDC motor, charging circuit, deep-cycle batteries, solar PV panels, switching, monitoring and safety circuits. Testing and demonstration efforts show that UNIMow may be a future lawnmower of our backyards for ecofriendly and more quite environment. The goal of this project is to develop a zero emission golf car that exhibits the same or better performance than its fossil fuel powered equivalent. With the results of testing, we hope to show that H-powered vehicles can prove viable sources of transportation that someday they could truly be replacement to their fossil-fueled counterparts. For this project it is unreasonable to build a full-scale vehicle with the resources we have, so we hope to prove that our system viability in a scaled fashion, hence why we are developing our project on a gulf cart chassis. System modules include a 500 Watt fuel cell to produce the electricity stored in batteries, a throttle with a "hall effect sensor", a controller, and a golf cart chassis. HYBRID BOAT DESIGN & IMPLEMENTATION (This is not the solar eBoat Project) Presenters: Michael Boomer and Ben Wagner Faculty Advisor: Dr. R. Pecen Sponsor/Industry Supervisor: CNS SOAR Grant, Iowa Energy Center, Douglas Bechthold, Bechthold Enterprise. Time: 4:20-4:40 pm The increasing cost of fuel has lead to renewed interest in efficient and environmentally friendly watercraft. This has also has changed the way that people use their boats. With prices hovering around $3/gallon last summer, driving to the beach and casting off is becoming a luxury. Our objective is to design and construct a hybrid drive train system to power a medium sized pleasure boat. This hybrid system will use a gas or diesel engine powering a generator to produce energy in the form of electricity. The electricity is then stored in a battery bank until it can be used at much more efficient levels. This is especially efficient because the generator will be running at peak efficiency at a supposed constant load, maximizing fuel efficiency. An electric motor is more efficient than using an internal combustion engine alone, even if the engine is allowed to run constantly at peak efficiency. V1 2 T1 120 V 60 Hz 0Deg 4 D2 B atteryPac k 1 48 V 2 3 M PLUG-IN HYBRID HYDROGEN POWERED VEHICLE Presenters: Cullen Hall & Neil Francois. Faculty Advisor: Dr. R. Pecen Sponsor/Industry Supervisor: Harris Golf Cars, William Controls, Optima Batteries, Alliant Energy, CNS SOAR Grant. Time: 4:00-4:20 pm MOTO R So larPanels 48 V AC/DC Conversion for Hybrid Boat Project. Two other senior projects; (1) design and implementation of a PWM based speed controller for 1 HP AC motor by Yao and Hussain, and (2) Ear Phone Design by Seth Reid are extended to May session for completion, testing and data collection. SOAR Grants 2006-2007.